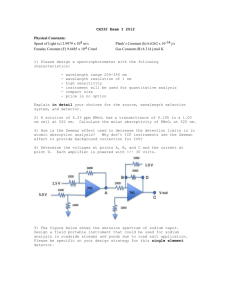

Ross Thesis - Clemson University

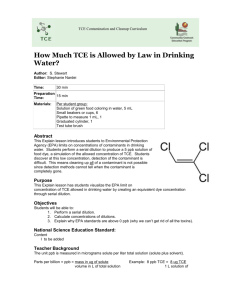

advertisement