WORD - virtualpharmtox.pharmacy.arizona.edu

advertisement

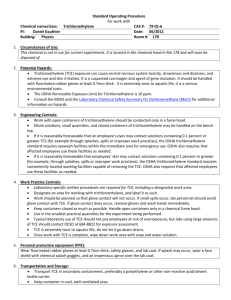

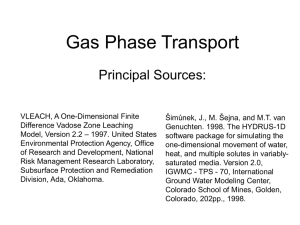

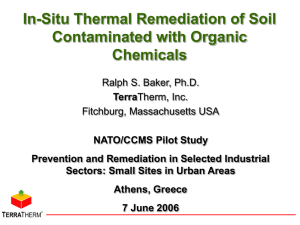

TCE Contamination and Cleanup Curriculum Costs and Benefits of Solvent Use Author: S. Stewart Editor: Stephanie Nardei Time: 2-3 class periods Preparation 30 min Time: Materials: Per student group: 0.01M KMnO4 solution, 6 mL Spot plate 0.1M HCl in dispenser, 1 mL 0.1M NaOH in dispenser, 1 mL 0.1M FeSO4*7H2O, 6 mL Abstract Students read information from the web to determine how polarity affects solubility, commercial uses for solvents such as TCE, health hazards associated with TCE, alternative solvents, and remediation techniques. Students will answer questions on a student data sheet and perform a cost and availability analysis of various solvents. Students perform a lab to determine the best pH and mixing order for optimal breakdown of KMnO4 in a simulation of a commonly used remediation technique. Purpose Students will explore the costs and benefits of the use of particular solvents such as TCE. They will also determine the optimal conditions for the breakdown of KMnO4, a commonly used TCE remediation technique. Objectives Students will be able to: 1. Explain the significance of polarity on solubility. 2. Describe several commercial uses for solvents such as TCE. 3. Describe several possible health concerns related to TCE. 4. Identify alternative solvents and assess their availability. 5. Compare costs and health benefits for TCE and alternative solvents. 6. Analyze costs and benefits of various remediation methods. National Science Education Standards Content Concept 1 PO 2. Describe the environmental effects of the following natural and/or humancaused hazards: Concept 1 PO 2. Develop questions from observations that transition into testable hypotheses. Concept 2 PO 1. Analyze the costs, benefits, and risks of various ways of dealing with the following needs or problems: hazardous wastes Concept 4 PO 2. Identify the indicators of chemical change, including formation of a precipitate, evolution of a gas, color change, absorption or release of heat energy. TCE Contamination and Cleanup Curriculum Teacher Background Production of TCE: -TCE is manufactured at only a handful of plants in the US. -PPG Industries obtains ethylene dichloride and reacts it with chlorine, hydrochloric acid and oxygen to produce trichloroethylene. -Dow Chemical reacts ethylene dichloride with chlorine alone to produce TCE and tetrachloroethylene. KMnO4 Lab: All reagents will be dispensed by drop. It is most convenient to provide them in dropper bottles, or alternatively with dedicated pipettes. KMnO4 stains badly, but is not harmful on the skin. Goggles should be worn. Related and Resource Websites Wisconsin Dept of Health & Family Services Chemical Fact Sheet, trichloroethylene http://www.dhfs.state.wi.us/eh/ChemFS/fs/TCE.htm TCE on Wikipedia http://en.wikipedia.org/wiki/Trichloroethylene ATSDR on TCE http://www.atsdr.cdc.gov/tfacts19.html World of Molecules on TCE http://www.worldofmolecules.com/solvents/tce.htm Activity 1. Teacher asks, “Why did the dye dissolve in ethanol but not water?” Students read about solutions, solvents, and polarity and answer the question on the student activity sheet. 2. Students read about commercial solvent uses and answer questions on the student activity sheet. 3. Students read about health concerns associated with TCE and alternative solvents. 4. Students analyze various solvents to compare price and health impact. 5. Students read about the various remediation methods and answer questions on the student activity sheet. 6. Students perform a lab in which they investigate the effects of pH and order of mixing on the efficiency of breaking down KMnO4. See student lab sheet. Closure Teacher prompts class discussion of questions on student activity sheet and discussion of lab results. Embedded Assessment: Assess student responses on student activity sheet and lab sheet. Homework N/A