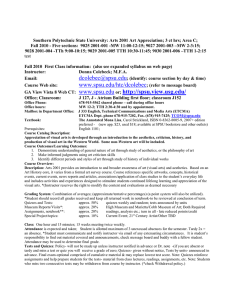

Syllabus - Faculty Web Pages

advertisement

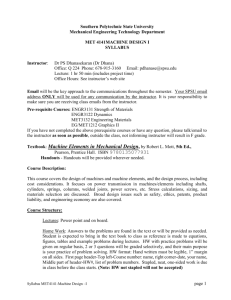

Southern Polytechnic State University Mechanical Engineering Technology Department MET 3132: Engineering Materials SYLLABUS – Fall 2012 Instructor: John F. Sweigart Office Q235/236 Phone: 678-915-4985 Lecture: Q221. T,R: 6:00-7:15 Office Hours: See schedule in website. Email: jsweigar@spsu.edu Lab: T or R at 7:30 pm in Q 136. Course Number and Title: MET 3132 – Engineering Materials Credits and Contact Hours (Lecture/Laboratory/Credit): 3/3/4 Course Description: A study of metals ceramics, polymers, and composites as related to design and manufacturing. Areas include corrosion, atomic structure, mechanical properties, failure theories, fatigue, creep, cold working, heat treating, alloying, and non-destructive testing. The lab work includes tensile testing, heat treating, impact testing, hardness testing, and corrosion. Prerequisites and Co-Requisites: ENGR 3131, Strength of Materials (or concurrently); CHEM 1211K, Principals of Chemistry I Textbook: Materials Science and Engineering: An Introduction; by William D. Callister Jr. and David D. Rethwisch, Eighth Edition, 2010. References: You will be guided to internet and library resources as needed. Course Outcomes: Students will develop understanding of fundamentals and application of the following topics: 1. General characteristics of major material groups. 2. Atomic and microstructure of materials. 3. Mechanical, chemical, electrical and thermal properties of materials. 4. Deformation and failure mechanisms. 5. Equilibrium phase diagrams and microstructure transformations. 6. Mechanisms of strengthening techniques. 7. Integration of information to develop material selection. 8. Communications skills, written and oral. 9. Concepts required for the Fundamentals of Engineering test. Grading: The components of the final grade will be weighted as follows: Area points 10% 15% 30% 25% 20% 100% HW 5 Quizzes (1 qz dropped) 3 Tests Lab-participation, report Comprehensive Final exam Total Grading: The student will receive a letter grade based on the following scheme. Overall % 88 – 100% 79 – 88 70 - 79 60 – 70 0 - 60 Grade A B C D F Lab reports will follow various formats issued by the Instructor. These will be explained in details during the lab. Passing grade averages are required for BOTH lecture and laboratory in order to pass the course. Lab experiments will be performed in student groups; however individual as well as group lab reports will be required as specified by the Instructor. Lab reports are due one week after the lab work unless specified otherwise by the instructor. After due date, late lab reports may be accepted with penalty of 50%. A student must actively participate in the Lab sessions in order to be part of report writing and get credit for a specific Lab. Students must ask for and make arrangements to attend a different lab session in case s/he anticipates absence on his/her lab day. Attendance Policy: Students are expected to be in every class and on time. While daily class attendance may not be taken, students are responsible for material covered in class as well as all assignments even if they are absent. Excessive tardiness and unexcused absences (more than 5 classes) may result in a lower grade or even course failure if the instructor feels such lack of participation is detrimental to the student's progress in the course. Late (more than 5 minutes) attendance in two classes is considered as one absence. Makeup Policy: Assignments are due at the BEGINNING of class on the due date. Late assignments may only be accepted with a penalty of 50%. Once solutions are provided/posted, no assignments will be accepted. Of course in unusual situations, as determined by the instructor, late assignments may be accepted. Exams/quizzes may only be made up if arranged before the scheduled period, and ONLY in the case of an excused absence as defined by the university policy. Academic Integrity: Honor system is followed in this course and the instructor trusts the students in applying strict ethics in their academic activities. Thus any act of academic dishonesty such as fraud and deception, including plagiarism, will not be tolerated at all and will be punished by academic and/or disciplinary sanctions. Any material not authored by the student but used in any submitted/presented work must be properly acknowledged. Cheating, including any evidence of the use of other students’ works, will result in severe penalties including zero for the assignment, failure in the course, and expulsion, consistent with university policy. Follow this link for further guidance on Academic Dishonesty: http://lovelace.spsu.edu/bharbort/conduct.html Students with disabilities: Students with disabilities who believe that they may need accommodations in this class are encouraged to contact the coordinator of disabilities services at 678-915-7244 as soon as possible to better ensure that such accommodations are implemented in a timely fashion. Please visit the disabilities services web page at SPSU for more information. http://www.spsu.edu/attic/Dis_Svcs.html Course topics and approximate lecture hours devoted to each topic: TOPICS COVERED Corrosion Atomic and crystal structure Failure and slip mechanisms Tensile, compressive, and torsional stresses Impact strength Fatigue Creep Failure Mechanisms Metal Properties Polymer Properties Ceramic Properties Composite Properties LECTURE HOURS 3 4 10 2 1 2 1 3 3 3 1 2 Laboratory projects: In tensile testing performed on a mild steel following heat treatment with various quenches, ultimate strength and elongation to failure are measured. Charpy impact tests are performed to compare ductility at different temparatures. Rockwell hardness tests are preformed on an end-quenched Jominy bar to determine hardenability of a steel. Corrosion tests are performed wherein each lab group assembles a dissimilar metal cell and tracks weight loss/gain over the course of the semester to determine the effects of different parameters. Students use heat treating furnaces, a tensile tester, calipers, an impact tester, hardness testers, a Jominy fixture, and a platform balance.