P&I BOOK NKLP March 2014

advertisement

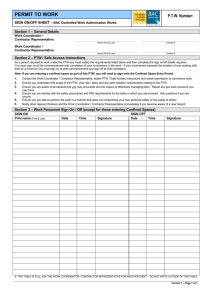

NATIONAL TRANSMISSION AND DESPATCH CO. LTD BOOK OF PROTECTION AND INSTRUMENTATION TRAINING PROCEDURES (TSG PROTECTION AND INSTRUMENTATION FIELD TRAINING SKILLS UPGRADING TRAINING PROGRAM) TSG TRAINING CENTRE NKLP LAHORE TSG NTDC P&I SKILLS UPGRADING TRAINING PROGRAM TABLE OF CONTENTS Sr. No. 1 2.1 2.2 2.3 2.4 2.5 2.6 COURSE CONTENTS Introduction Safety Principles Electric Shock First Aid Artificial Respiration Low Voltage hazards Grounding and Bounding, Absolute Limits of Approach, Use of PPE 2.7 2.8 2.9 15 Permit to Work(PTW) 17-22 Practical project on PTG installation, first aid and 23-25 artificial respiration. P&I Tools and T&P like clamp on ampere 26-64 meter,secondary injection set,universal set,C&DF test set, energy meter set and CT analyser along with relay test performas for different kind of protection in field. Bus bar diffrantial literature and performa for 65-88 inspection at grid station. Teleprotection and cross trip protection scheme along 89-100 with check sheet during field visit. Electrical drawings for AC,DC schematic and wiring 101-120 drawing for demonstration Annunciation and alarm system 121-131 Breaker failure relay literature and test performa for 132-162 testing during OJT Batterey and batterey charger theory along with Vol-II inspection sheets for checking / calibration of battery charger in field. Energy meter theory and testing procedure for single VOL-III and three phase energy meters (Electromechanical/Numerical) 3 4 5 6 7 8 9 12 Page No. 1-5 6-12 13 14 14 15 15 TSG NTDC GRID MAINTENANCE SKILLS UPGRADING TRAINING PROGRAM 1. INTRODUCTION Technical Services Group (TSG), was established in 1985 under the technical assistance and financing of Canadian International Development Agency (CIDA) under CIDA/WAPDA Project Phase-II. The Project Phase-II was a continuity of the already completed CIDA/WAPDA Project Phase-I, under which the GSO Training Center Tarbela was established in 1980, to meet with the requirements of technical training of Grid System Operation (GSO) staff. The objectives of TSG were to set up a pool of technical experts to improve the performance of Grid System through consultancy services and providing training for capacity building of the workforce of GSO in all the three major disciplines: Grid station maintenance, Protection and instrumentation (P&I) maintenance, Transmission lines maintenance. CIDA/WAPDA Project Phase-II was completed in 1990, since then TSG was working indepedantly. At present (in line with the original strategy) the P&I training has two semesters. The first semester covering theory of protection relays and lab work at GSO Training Centre Tarbela, whereas the second semester covering on-job P&I training at TSG Training Centre, NKLP, Lahore. Maintenance has become nowadays an important factor due to many reasons. Economic and legal considerations are among the most significant, for example extending the service life, reducing life cycle costs, reducing downtimes, safety aspects and environmental protection regulations. In addition to the purchase costs, the profitability of switchgear and controlgear in both the high and medium-voltage systems depend above all on the calculated operating costs for the entire service life. Therefore, to meet with the current requirements of up-gradations in the electromechanical technologies, emerging modern trends of maintenance, standards/specifications and awareness of the technical staff of grid stations these training manuals have been revised. It is mandatory for the user of this manual that he must possess theortical knowledge of electromechnical/solid state/numerical relays and has completed semester-1 of the P&I training at GSO Training Center Tarbela. TSG NTDC P&I SKILLS UPGRADING TRAINING PROGRAM 2. CONCEPT OF MAINTENANCE 1. WHAT IS MAINTENANCE? The term “maintenance” is encountered frequently, though it is used with different meanings. Its overall concept includes inspections, scheduled maintenance and corrective/non-scheduled maintenance. As per IEC standard/specifications, maintenance is the combination of all technical and administrative actions, including supervision actions, intended to retain an item in, or restore it to, a state in which it can perform a required function. The proper maintenance also ensures correct operation of grid station equipment permanently over its design life, even longer if it is justified economically and technically. Generally the maintenance work is categorized as scheduled maintenance and non-scheduled maintenance. 1.1. SCHEDULED MAINTENANCE The preventive maintenance carried out in accordance with an established time schedule. Scheduled maintenance covers all measures aimed at retaining the design state of the technical equipment belonging to a system and may take place as and when required or in regular/fixed intervals of time. Scheduled maintenance includes such activities as cleaning and washing, conservation, lubrication and where necessary amending or replacing parts subject to wear and tear. Scheduled maintenance also involves preparation of maintenance schedules, carrying out the specified work and dealing with feedback relating to this work. 1.2 NON-SCHEDULED MAINTENANCE Non-scheduled/corrective maintenance is often not in accordance with an established time schedule and usually needs a result of malfunction or unexpected defect. Non-scheduled/corrective maintenance covers all measures aimed at restoring the designed state of the technical equipment belonging to a system. Repair works and part replacement are typical types of corrective maintenance. It also involves planning, handling requests for performing/checking and evaluating the necessary measures (functional tests etc.). It is worth mentioning that an effective preventive maintenance program always minimizes emergency maintenance, breakdowns and damages of grid station equipment. 2. PREVENTIVE MAINTENANCE PROGRAMME The responsibility of carrying out maintenance work always lies with the owner of the equipment i.e., NTDC. The company is under an obligation to observe all the valid rules and specifications. The specifications of maintenance work must be based on certain requirements, standards, specifications and the guidelines supplied by the manufacturer. The main activities of a comprehensive preventive maintenance programme are as under: 2.1 MAINTENANCE INTERVALS There are three main criterias, which determine the maintenance intervals for protective equipment: - The recommended time and service period - The number of operations It is a universal practice that most of the Relays testing work is carried out on the criteria of recommended time periods of service life of the protective equipment (daily, weekly, monthly, quarterly, annually, 5 to 10 yearly, 20 yearly, etc.). Maintenance is carried out rarely on the criteria of rate of operations. Regular or scheduled inspections, scheduled maintenance, non-scheduled maintenance all are the basic features of a preventive maintenance program. 2.2 INSPECTION Visual inspection/investigation of the principal features of control gear and other equipment in service belonging to a system carried out, without dismantling, to evaluate the actual status. Inspections are also described as, walk around visual inspection from distance keeping in view the safe limits of approaches. Shutdown of the equipment is not involved normally. On the bases of inspection data, short and long-range work programs for carrying out preventive maintenance are prepared to meet with the best possible level of operational availability and reliability of the protective system. Overhauling may be categorized, as minor overhauling and major overhauling, depending upon the specific instructions of the manufacturer and / or local experience and policy of the company. TSG NTDC GRID MAINTENANCE SKILLS UPGRADING TRAINING PROGRAM 3. JOB PLANNING OBJECTIVE: You will do job planning for routine and emergency grid maintenance jobs from start up to completion of the job, following the procedure and steps given below. A) JOB PLANNING PROCEDURE AND STEPS Job Planning is the name given to the process of thinking to pool ideas or opinions to do some job in a safe and efficient way. The job may be routine and preventive maintenance work or an emergency work. Jobs are executed more efficiently and effectively when jobs are planned well and all concerned know what is expected. The key points to do consider for planning a job are as given below: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Follow the work program. Arrange testing procedures. Arrange equipment manual and drawings. Arrange previous testing records. Arrange the spare parts, if required. Arrange T & P and test equipment needed. Estimate and arrange to meet the expenditure involved. Estimate the number of man-hours and the length of .time required to complete the job. Arrange to get co-ordination of the other work groups ( grid maintenance, T/L etc.), if needed. Arrange shut down of the equipment to be worked on, if needed (refer procedure for PTW). . Inspect job site to look for: 11.1 Hazards, 11.2 What equipment is to be de-energized to get safe working clearances? 11.3 Isolation points & grounding facilities. 11.4 What types of aerial devices (i.e. scaffold, bucket truck, ladders and cranes) are required? 11.5 Is there enough room/space for aerial devices and the ground condition permits to be fix/move them. 11.6 Approach roads condition. 11.7 Other information of job site that you think necessary for execution of the job. 12. Conduct a tailboard conference or meeting with the crew member to brief them and ensure that each person knows what to do. 13. Conduct a job safety analysis. The purpose of job safety analysis is to uncover inherent or potential hazards, which may encounter in the work environment and develop possible ways in which the electrical hazards can be eliminated or effectively controlled. TSG NTDC GRID MAINTENANCE SKILLS UPGRADING TRAINING PROGRAM 4. JOB SAFETY AWARENESS AND SAFETY CODE OBJECTIVE You will get safety awareness and follow the prescribed safety rules, guidelines while on work for your own safety, of fellow workers, and of the company’s property following the safety information given hereunder. It is the responsibility of man-incharge and of each crew member to constantly be on the lookout for safety hazards and to take definite steps to eliminate or control all identified hazards. 4.1 INTRODUCTION Prior to undertaking, any of the maintenance procedures outlined in this manual, proper work protection shall be established as necessary in accordance with the company’s Safety Code. All work activities shall comply with applicable safety rules and regulations. In addition to the above, a safety hazard identification exercise shall be undertaken. In a work place, hazards are always expected to the workers and/or the equipment. The unsafe acts and unsafe conditions increase the chances of accidents whether fatal or non-fatal. Flow of unwanted energy also presents accidents. Safety can be achieved only through intelligence, cooperation and an understanding of adherence to safety measures. The theme of safety policy of the companies should be as follows: “No Operating Condition or Urgency of Service Can Ever Justify Endangering the Life of Anyone” 4.2 FUNDAMENTALS OF THE SAFETY The electricity companies i.e. NTDC, DISCOs, GENCOs, etc. must have a welldefined safety programme to provide safe and healthy environment to their workers/employees with the following objectives: - The prevention of accidents, injuries and weaknesses of professional skill shall be integrated into all aspects of every work activities performed for or on behalf of company. - All levels of management and supervision shall be responsible for providing a safe working environment as well as elimination of the factors causing health hazards. They shall also be responsible for provision of adequate protective equipment, tools and devices for the safe execution of works and shall contribute for the development in performing their work so as to ensure their safety. - Management shall provide adequate training to employees in phases so that they become well acquainted to perform the assigned works safely. - All persons whether employees of companies or contractors working on a site, shall comply with the applicable safety legislation of the Government of Pakistan. In addition, they shall comply with safe working practices of their companies, already established, to ensure their own safety as well as fellow workers. - Contractors working at sites involving electrical hazards shall perform the work with specially trained personnel following the procedures generally recoganized by companies to be safe and adequate for work in proximity to live electrical apparatus. equipment being made live. - Specific safety requirements for contractors shall be written in the contract documents. - All levels of management and supervision shall organize and administer a safety programme to develop safety culture among the employees. The safety directorate shall promote and monitor safety programmes on regional, circle and divisional levels in company. 4.3 IMPORTANT DEFINITIONS Circuit means and arrangements of devices or media through which electric current can flow. Conductor means a component intended to carry electric current. Danger Notice means, a notice attached to a live electrical apparatus, calling attention to the danger of touching or interfering with such apparatus. Accident is the result of an unwanted energy flow OR the result of any unsafe-act or unsafe-condition that persists during execution of work. Dead means de-energized and earthed. Approved used in this code means approved by company. Earth means, the conducting mass of the earth whose electric potential at any point is continuously taken as zero. Apparatus device or assembly of devices that can be used as an independent unit for specific function. Authorized Person means a person who is authorized to perform the duties pertaining to his employment, the authorization being by an officer of company, empowered for that purpose. Barrier is a temporary non-conducting obstacle that is placed to limit the distance that the workers can reach or approach to anything that is at a different electrical potential from them OR a means to control energy flow. Body Internal Resistance is the resistance of the body after the skin has been punctured. Bonding is the process of electrically connecting conductive objects together to bring them to the same electric potential. Caution Notice means a notice attached to dead electrical apparatus to prevent such De-energized means, disconnected from all sources of electricity. Earth Connection means a metallic conductor for connecting electrical equipment to earth. Earth Mesh means a network of a copper conductor burried in the earth and connected with earth mass through earth electrodes to control step and touch potential and to provide easy earth connection to the equipment. Electric Shock is the sensation and muscular spasm caused by electric current flowing through the body. Effects of electric shocks are mild tingling sensation, severe muscular contractions, respiratory paralysis, heart stoppage and death. Electrocution is the death caused by electric current flowing through the body. Equipment means any item used for such purposes as generation, conversation, transmission , storage, distribution are utilization of electrical energy such as machines, transformers, apparatus, measuring instruments, protective devices, appliances, etc. Hazard is the potential for an unwantedenergy-flow to occur OR any unsafe-act or unsafe-condition that may cause an accident to the worker or damage to property. Hot or Live (or alive) means electrically energized. Human Body Resistance is the skin resistance and the major contributor to total body resistance at voltages below 600 volts AC. Factors that affect skin resistance are pressure of contact, contact surface area, duration of contact and moisture content of the contact surface area. Insulated is a term used to describe a device or medium isolated from earth or other potential by an insulating material. However, it shall not be considered safe to touch unless proper personal insulating protective equipment is used or apparatus or line is made dead. Insulating Protective Equipment is protective equipment made of rubber or other approved insulating material used during work on energized lines or equipment. Insulator is a component designed to support and insulates a conducting body. Nominal Voltage means a suitable approximate value of voltage used to designate or identify a system. Personal Protective Equipment (PPE) is an equipment used/ worn by a worker for his safety during work. Potential is the degree of electrification at a point in an electric circuit with respect to some other point of reference such as earth. Step Voltage The potential difference between two points one meter apart on the earth’s surface in the direction of maximum potential gradient. System means an electrical system in which all the conductors and apparatus are electrically connected to a common source of voltage. Touch Voltage The potential difference between a grounded metallic structure that can be touched and a point one meter away on the earth’s surface. Voltage between conductive parts when touched simultaneously by a person or an animal. Working Clearance is the minimum distance that workers shall approach anything that is at a different potential from them. Working Space is the amount of room required for live conductors to perform a job safely. 4.4 BASIC SAFETY GUIDE LINES Personal safety is a primary feature of our daily work, whether at home or office or field so all the employees of the company, mainly the un-trained and having multi-nature jobs, must become familiar with these basic safety guidelines. General Principles: Accident prevention can be accomplished only through possessing and applying safety know how and whole hearted cooperation of all members of the organization. Learn and understand the following five basic principles in job safety to deal with the hazards: IDENTIFY the Hazards. ELIMINATE the hazards wherever practical. CONTROL the hazards when they cannot be eliminated. PROTECT against injuries in case a hazard gets out of control. MINIMIZE the severity of an injury, if an accident has occured. -Neither management and supervision, nor the Safety Code can prevent accident without the help of each employee. -Unsafe workers are a danger to themselves, their fellow workers, the public property and the equipment with which they work. Due care and attention to all safety rules and devices is essential not only to prevent injury to the workers but also to protect equipment. -Capable and mentally alert employees will avoid accidents by learning all they can about their work, using proper safeguards, protective equipment, and avoiding shortcuts and make shift work methods. -Good operation is safe operation. This is true for both employees and equipment. A job done safely is job done efficiently. -Accidents do not “just happen”. Accidents are the natural result of unsafe conditions or unsafe acts, usually a combination of both. Machinery and equipment generally are manufactured to perform safely within limits of design. In fact, statistics show that more then 90% of accidents are due to the human element, such as failure to use safety devices and observe safety rules and procedures. UNSAFE CONDITIONS: Some examples of unsafe conditions which may cause accidents are:Improper Guarding such as unshielded moving parts of machine, in-barricaded floor openings and excavation, unenclosed high voltage equipment, lack of protective equipment and insufficient warning signs etc. Defective Material or equipment such as mushroomed-head chisels, split handles, deteriorated poles, poorly manufactured or weak equipment. Hazardous Arrangements such as those due to poor housekeeping at work locations, unsafe planning or inadequate working space. Insufficient Light unsuitable location producing glare or objectionable shadows. Improper Ventilation such as insufficient change of air or presence of harmful vapor, dust or gas. Unsafe Clothing that fits loosely and can become entangled in wires and machinery, and failure to use goggles, proper shoes and insulated gloves or sleeves. Unsafe Design and Construction due to deviations from standard design and specifications and poor workmanship. UNSAFE ACTS: Some examples of unsafe acts which may cause accidents are: Operating Without Authority or Warning such as closing switches without authority, operating hoists and trucks without warning, failure to place warning signs or signal man where needed, failure to block equipment against unexpected movement, failure to observe work clearance procedures. Operating or Working at Unsafe Speed such as driving too fast, throwing material or tools to another worker, jumping from vehicles or platforms or running. Making Safety Devices Inoperative such as removing guards from machines, using oversize fuses, blocking safety valves, bypassing interlocks and isolating fire protection etc. Use of Unsafe Equipment or Improper Use of Equipment such as using dull cutting tools, mushroom-head chisels, and pipe extension on wrenches not designed for them, or the wrong tool for the job, or using hands instead of hand tools. - Noise energy, - Pressurized fluid energy. Unsafe Loading such as overloading cranes and winches, carrying too heavy load. Wrong or improper use of this energy can cause accidents. The flow of wanted energy is consumed in accomplishment of work e.g. current flow in conductor, mechanical energy in rotating machine, etc. Where as flow of unwanted energy is a hazard e.g. making inadvertent electrical contact, being caught in rotating machinery, etc. Placing or Leaving Objects where they are likely to fall. Mixing Improper Packing or combining chemicals to form a dangerous mixture. Taking Unsafe Position or Posture such as working on live conductors from above instead of below, walking under suspended loads or too close to openings, lifting while in awkward position, entering areas where there are dangerous gases or fumes, passing on curves of hills, riding on running boards or other unsafe places on vehicles. a) Body mechanics safety awareness Body mechanics energy is derived from the use of the body muscles and from the action of gravity on the body. Normal activities such as walking, bending, twisting, etc. and the more work-oriented activities such as lifting, carrying, pushing, pulling and climbing, are examples. Working on Equipment without Taking Proper Precautions such as installing and removing temporary earth, cleaning, oiling or adjusting moving machinery, and working on or near live electrical equipment. Body mechanics injuries may be such as pulled muscles, slips and falls on the same and different levels. Other injuries may also be caused by: Distracting, Teasing or Startling such as practical joking, horseplay, quarrelling or annoying. -A falling injury from a platform or tower due to involuntary muscular response to an electric shock. Failure to Use Safe Clothing or Protective Equipment such as failure to use insulated gloves, hard hat or goggles. -From striking another object due to involuntary muscular response to a sudden high intensity noise level, operation of an air blast breaker, or release of a high-pressure fluid. 4.5 DIFFERENT FORMS OF ENERGY COMMONLY INVOLVED IN DOING WORK AND THEIR SAFETY ASPECTS b) Electrical energy safety awareness Different forms of energy that we commonly encounter in our every day work have been identified as: The basic injury hazard from electrical energy is caused by the flow of current through the body, which may be established by: - Body mechanics, - Electrical energy, - Chemical energy, - Mechanical energy, - Heat energy, - Light energy, -direct physical contact, -spark-over or flashover, -electromagnetic induction, -electrostatic induction. In the work environment, hazards from subsequent absorption through the lungs. electrical energy may be encountered when: These substances include gases like carbon monoxide, finely divided particulate matter -working on electrical equipment, like asbestos dust, and suspended liquid -working adjacent to live electrical droplets like hydrochloric acid mist. Gases equipment. absorbed into the lungs pass directly into the blood and may replace necessary oxygen, thus The electrical hazard i.e. flow of current causing asphyxiation. Other substances, through the body may result in: which enter the lungs, can eventually enter the bloodstream and be deposited in the bones -damage to the body tissues caused by the or organs. heat produced by the current flow, -malfunction of vital body organs, -Toxicity -body mechanics injury because of unplanned A toxic effect can result from a one time physical movement. exposure or from a long-term exposure. In this context, it should be noted that some c) Chemical energy safety awareness chemicals used in industry are known to cause cancer. Chemical energy is the energy released when an element or combination of elements d) Mechanical energy safety awareness interacts with other matter. Hazardous chemicals are those chemicals that can react Mechanical energy is the energy in an object with or be accumulated in body tissue, because of its position or motion. altering it either temporarily or permanently. Because of its position, such as charged A potential hazard exists when employees springs, elevated objects, and because of its work with chemicals, or where chemicals are motion, such as rotating objects, moving stored. objects. The harmful effect to the body varies with the chemical type, the concentration, length or exposure, and in some cases, individual reaction to the chemical. These effects may be apparent immediately or develop over extended periods of time. Handling of used SF6 gas, Electrolyte of lead acid D.C battery cells (dilute sulphuric acid-H2SO4) requires special precautionary measures. Mechanical energy may be found in practically all work areas and activities, for example: -Gastrointestinal Absorption Toxic materials, if swallowed, can damage the gastrointestinal tract. They are absorbed through the stomach and intestines, causing damage to vital organs such as heart, liver, kidneys and brain. -Portable tools – wrenches, grinders, chain saw, and hand drill. -Mobile equipment – truck, forklift, snowmobile, crane, tele-lift. -Stationary machinery and equipment – lathe, drill, press grinder, compressor. -Structures – scaffold, ladders, storage bins, towers. -Winds and wind age - handling material in -Absorption through the Lungs the wind, wind blows dirt in your eyes, Most industrial poisonings occur because of pressure differentials in buildings (doors), inhalation of a harmful substance and truck doors slamming on your fingers. e) Heat and Cool energy safety awareness Heat is a form of energy, which may be more commonly identified as “hot’ or “cold”. Man’s body temperature is 98.6oF (38oC), therefore, anything higher is considered as hot, and anything lower is considered as cold. Frostbite and/or sunburn are two fairly common examples or the results of excessive heat-cold and hot. Some other forms of heat energy are: -open fires (heaters), -hot liquid (molten solder), -hot metals (welding, engine exhausts), -dry ice, -Bare metals – extreme cold, f) Light energy safety awareness: -Materials and interaction with other energy forms Ultraviolet radiation causes physical and/or chemical changes in some materials. This may result in hazardous conditions because of adverse changes to the electrical or chemical properties of the materials. For example: -polypropylene rope, -Rubber gloves and electrical cover-up, -Hoses, -Gasket material, -Live-line tools, Oxygen produces ozone in the presence of ultraviolet radiation. Cleaning fluids and solvents (chlorinated hydrocarbons) produce toxic gases like phosgene. Flashes may cause involuntary movements. The eyes have to be given time to adjust to lighting changes (welding arc). Light energy is a form of electromagnetic radiation very close in wavelength to ultraviolet radiation, which is invisible. The effects of intense visible light and invisible g) Noise energy safety awareness ultraviolet radiation on vision, skin, some material, or other energy forms may create a Noise is defined as unwanted sound. It does hazard such as: not have to be loud. It could be the noise of a truck, jet engine or a dripping tap. Our safety -Vision concern is the prolonged exposure to The eyes may be damaged by exposure to excessive noise that can cause permanent ultraviolet radiation from such sources as hearing damage. welding, power switching, the sun, and unjacketed mercury vapor lamps. The damage The delicate inner ear is the part that is may be temporary or permanent depending on damaged by repeated exposure to noise. The radiation intensity, length of exposure, type of degree of damage to the hearing ability is eye protection worn, and the angle at which dependent upon the noise intensity, frequency the radiation strikes the eye. Extreme damage and duration of exposure. may result in blindness. A hazardous noise area exists if the following Excessive visible light or glare causes condition can be identified: temporary loss of vision and may cause discomfort in the eye, eye fatigue and -If you have difficulty in carrying out normal headache. It rarely causes permanent damage. conversation. Gas welding and electric welding with out -If you experience head noises or ringing in proper protection of eyes is a serious hazard. the ear after noise exposure. -If you experience temporary loss of hearing after being exposed for several hours to the noise. h) Pressurized fluid energy safety awareness (liquid and gases) 4.6 ELECTRIC SHOCK Electric shock is the after effect of electric current flow through the body by application of the voltage across the body. Some conditions that can cause this are: The term “fluids” applies to all substances that offer no resistance to change of shape. Fluids are divided into two classes – gases -direct physical contact with an energized and liquids. Gases are easily compressed; conductor or component where a current from liquids are virtually incompressible. the source through the body to ground. A pressurized fluid in either gas or liquid form, has stored energy. Because gases are very compressible, considered amounts of energy can be stored up under pressure. A gas under pressure can be turned into a pressurized liquid; but when released from its containment, the liquid rapidly returns to the gaseous state. -spark-over or flashover from an electric source to the body with a resultant current flow through the body to ground. Where the pressure on a fluid is below normal atmospheric pressure, it is termed to be under vacuum. In the source-body-ground circuit source voltage, circuit resistance, contact resistance, body resistance and the earth resistance or the main variables that affect the flow of current through the body. -electromagnetic and / or electrostatic field when bridge a human body, an electric may flow through the body without physical contact or arcing. The safety considerations for pressurized fluids energy are the hazards from the uncontrolled release of the stored energy. Basic Hazards to human beings as a result of electric shock are the followings: Some examples of pressurized fluids energy in the work environment are: Liquid -The sensation of the shock alone can cause petroleum gases, high-pressure air and oil an involuntary movement that can cause lines, bottled gases, aerosol cans, and vacuum physical harm due to bumps, slips, falls, etc. tanks. -Physical damage to the body caused by the Pressurized fluids may react with many other heat generated by the current passing through energy forms: the body. -Ceasing of the functioning of vital body Chemical energy - The gases may be toxic. organs caused by the passage of current. Heat energy - The gases may be flammable and explosive. -Physical damage to the body in the form of Noise energy - The sudden release of high- external burns caused by the ultraviolet light pressure fluids could result in damaging noise produced by an electrical arc. levels. Mechanical energy Struck by a flying 4.7 RESUSSITATIOIN AND FIRST AID object as a result of the high-pressure fluids being released. Resuscitation or Artificial Respiration means revival of an unconscious person to life i.e. rising again from dead or restoration to life. First aid is the immediate care of the injured or sick person. Basic first aid is essential for the treatment of injuries, which may accompany electric shock. The treatment of bleeding wounds and burns is essential for the preservation of life after successful resuscitation is achieved. Principles of first aid (the three P’s) -Preserve life, -Promote quicker recovery, -Prevent further aggravation of the wound. Air is an example of this. Under normal condition, dry air is a fairly good insulator, however, when it is sufficiently by an electric potential it can become ionized. In ionized state, it becomes a good conductor. Electrical conductors and their component parts are designed so that they have sufficient clearance from ground, such that the intervening air is not stressed on the point where it becomes a conductor. However, when you bring the ground plane closer to the conductor by tools or parts of your body, there is always the danger that you overstress the intervening air to the point where it conducts i.e. an arc is former across the air path. Scope of first aid (the four D’s) In this manner, you do not have to touch a Diagnosis- Find out what is wrong by live component in order to receive a shock. history, signs or symptoms. The limit of safe approach considers this Decide- On extent of treatment, remove cause phenomenon. The staff required to work in an of the injury. environment influenced by electrical energy Do it- Promptly and calmly. have been classified based on their Dispose- off the casualty: Send to do knowledge, training and experience and safe doctor, hospital or home as conditions may limits of approach according to different warrant. levels of voltage established. These classifications are as given below: Priority of treatment ((the three B’s) 1) Work by unqualified/untrained Breathing- Apply artificial resuscitation as workers: Unqualified and untrained persons soon as possible. shall not be allowed to approach, or work, or Bleeding- Apply dressing to control or stop allow any material or equipment to approach, bleeding. closer to exposed live electrical apparatus Burns- Apply dry dressing and transport to than the distances given in table 1. medical aid as soon as possible to prevent or to lessen shock. 2) Work by qualified/trained workers: The worker’s position in relation to the 4.8 CLASSIFICATIOIN OF WORK IN exposed live electrical apparatus shall be THE ENVIRONMENT INFLUENCED BY established such that movement of his body or conducting tools or equipment will not result ELECTRICAL ENERGY in any encroachment upon the distances given Every substance is to some degree a in table 1. conductor of electricity. Metals are good conductors-insulators are very poor 3) Work by especially qualified/trained conductors. Under the stress of electric workers: The person-in-charge shall potential, some poor conductors can take on carefully study the work location, and the changes that make good or better conductors. possible extreme accidental or unplanned movements of workers and any conducting For specially 750 to 15 0.31 m (1 ft) tools and equipment, which they may be trained 000 using. The extreme boundary of the resulting Workers required work area shall not encroach nearer -do15 000 to 0.46 m to exposed live apparatus than the absolute 50 000 (1.5ft) limits of approach given in table 1. These -do50 000 to 0.92 m (3 ft) absolute limits of approach must never be 150 000 reduced unless the work is being done by -do150 000 to 1.22 m (4 ft) qualified employees having appropriate in the 250 000 use of protective equipment, such rubber -do250 000 to 2.75 m (9 ft) gloves, hose, hoods or barriers, or in 550 000 accordance with approved bare hand, live line maintenance procedures. Table 2: Safe limits of approach for Un4) Un-insulated boom-type equipment insulated boom-type equipment e.g. mobile e.g. cranes, power shovels, aerial ladder, cranes, etc. while working in vicinity of live pole derricks, etc. Only qualified personnel electrical apparatus shall use equipment of types as said above near live electrical apparatus. All work shall Description Nominal Limits of be done in accordance-approved procedures, of Phase to Approach and the distances from live apparatus given in Equipment Phase table 2 shall always be maintained. Voltage Table 1: Safe limits of approach for Range workers while working in vicinity of live (Volts) electrical apparatus For cranes 750 to 15 3.05 m (10 and power 000 ft) Classification Nominal Limits of shovels of Workers Phase to Approach -do15 000 to 3.05 m (10 Phase 50 000 ft) Voltage -do50 000 to 3.05 m (10 Range 150 000 ft) (Volts) -do150 000 to 4.58 m (15 For untrained 750 to 150 3.05 m (10 250 000 ft) workers 000 ft) -do250 000 to 6.10 m (20 -do150 000 to 3.58 m (15 550 000 ft) 250 000 ft) For Aerial 750 to 15 0.92 m (3 -do250 000 to 6.10 m (20 Frames and 000 ft) 550 000 ft) ladders For trained 750 to 15 0.92 m (3 -do15 000 to 1.22 m (4 workers 000 ft) 50 000 ft) -do15 000 to 1.22 m (4 -do50 000 to 2.44 m (8 50 000 ft) 150 000 ft) -do50 000 to 1.53 m (5 -do150 000 to 3.05 m (10 150 000 ft) 250 000 ft) -do150 000 to 2.14 m (7 -do250 000 to 4.58 m (15 250 000 ft) 550 000 ft) -do250 000 to 3.66 m (12 550 000 ft) Table 4: Conversion of commonly used Table 3: Minimum clearance o overhead lines (at 150 F/65.5oC) Weight/mans DESCRIPTION 400V & BELOW 11KV & 33KV ft(m) ft(m) 19 (5.8) 20 (6.1) b) Along a Street 17 (5.2) 20 (6.1) c) Across Private 15 (4.6) 15 (4.6) Across Country a) Across Street or intersection and places inaccessible to vehicularTraffic - - - Inside Station Limit 31(9.5) 33(10.0) - outside Station Limit 23(7.0) 25(7.6) - Vertical 8(2.4) 12(3.7) - Horizontal 4(1.2) 6(1.8) Bottom/Earth Part of 2(0.61) 6(1.8) Telegraph Lines 4(1.2) 6(1.8) 400 Volt Lines and 2(0.61) 6(1.8) 11KV Lines - 4(1.2) 33KV Lines - 6(1.8) 66KV Lines - - 132KV Lines - - 220KV Lines - - 500KV Lines - - Rivers and Major 132KV Pressure 220KV ft(m) 1 Ton ft(m) = ft(m) 1000 Kg 20(6.1) 1 Kg 22(6.7)= 23(7.0) 2.204 Pound (lb) 1 lb = 0.453 Kg 500KV ft(m) Atmosphere 27(8.2) (standard) = 101.325 Kpa = 14.7 psi Length Property, Footpath Roads and Highways 66KV factors Canals from H.F.L Railway Track Building Part Lines (Insulated services, Guys, Earth Wire etc.) Below 1 micron micro meter 1 mil 26(7.9) 26(7.9) 25.4 m 30(9.1) 30(9.1) 1 inch 2.54 cm 1 mm 34(10.4) 0.03936(11.0) inch 26(7.9) 1 foot28(8.5) 0.305 m 1 m 17(5.2) 15(4.6) 3.280 20(6.1) foot 15(4.6) 1 mile11(3.4) 7(2.7) 1.609 km Gauge pressure = 1.0 = Actual pressure+ = Atmosphere 31(9.45) pressure 30(9.1) 30(9.1) = 1 bar = 100 = Kpa = 0.1 Mpa 37(11.3) 39(11.9) 1 Kpa = 10 mbar 29(8.8) = 30(9.1) 1 Mpa = 10 bar 20(6.1) = 25(7.6) 1 bar = 14.5 25(7.6) 30(9.1) psi = 1.02 Kg/cm2 13(4.0) = 15(4.6) 1 psi = 0.07 2 Kg/cm Force/moment of 1 Kg/ cm2 = 14.21 psi force/torque 9(2.7) 11(3.4) 13(4.0) 15(4.6) 1 Torr = 7(2.1) 9(2.7) 11(3.4) 13(4.0) 1 Kg = 133.328 Pa = 1.33 mbar 9.806 N 7(2.1) 1 Pa = 1 N 9(2.7) 11(3.4) = 13(4.0) 7(2.1) 9(2.7) 11(3.4) 13(4.0) 0.0075 torr 0.102 Kg 1 Kpa = 7.5 10(3.0) 1 Lb 12(3.7) 14(4.3) = 16(4.9) m torr 4.448 N 12(3.7) 14(4.3) 16(4.9) 1 mbar = 0.75 1- N 16.5(5.0)= 18(5.5) torr 0.224 Lb22(6.7) = 1 pound foot = 1 psi 6.894 Kpa 1.355 Nm = 1 Nm = 1 Kpa 0.145 psi 0.749 lb.ft 1 Kgm = 1 Kg/ cm2 = 98.066 Kpa 9.806 Nm = 1 Nm = 1 Kpa 0.010 Kg/Cm 0.102 Kgm 26(7.9) 1 Kgm 7.336 lb.ft 1 lb.ft 0.138 Kgm Temperature C=(F-32)x5/9 F=(Cx9/5)+32 = 1 Kg/litre = 10.1 Pound per gallon = 1 Pound per gallon = 0.099 Kg/litre 1 atm = 29.98 inch of Hg at 20oC 14.9 Psi = 76 cm of Hg at 20oC Vacuum = (-)ve pressure < 1 atm 1 torr = 1 mm o Hg at 20 C 1. PTW introduction TSG NTDC P&I SKILLS UPGRADING TRAINING PROGRAM 5. PERMIT TO WORK (P.T.W) OBJECTIVE: You will arrange shutdown of a power equipment at a grid station for maintenance purpose. After getting approval of shutdown from the competent authority, you will get/cancel Permit to Work (PTW) and you will use the recommended work protections to perform maintenance work safely by observing the procedure given and the applicable safety rules. As per WAPDA/PEPCO rules, any type of schedule/non-scheduled maintenance work on any power equipment at a grid station must be arranged by an authorized person. Before starting work, the authorized person will get approval for shut down of the equipment from the competent authority. Then after approval of the competent authority, the authorized person himself or the other authorized person will obtain Permit to Work (PTW) from the shift engineer/shift in charge. After having PTW and following the instructions therein, he will start the work and cancel PTW after completion of the work. A properly issued PTW and instructions therein implemented provide sufficient work protection. Severe and fatal accidents result by ignoring minute activities in this process. 2. Description of PTW PTW is a legal document of WAPDA/PEPCO, which is issued in the name of an authorized person to perform maintenance work on power equipment. A PTW has two copies double side printed red & white (Reference copy attached). When issued one copy is left in the PTW book as office copy and the second is handed over to the person in whose name it is issued and the same he will return to the issuing authority after doing the work or when he wishes. Station operator cannot make any switching operation on the equipment, which is under PTW until he does receive back the PTW duly signed by the person in whose name it was issued. 3. How to Apply for Shutdown The applicant must be an authorized person (XEN/DM, AE/AM, Test Inspector / Lab Assistant). For scheduled work, apply a written request at least 72hours before the date/time of the requisite work to be done. For non-scheduled/emergency work there is no restriction of pre-apply time. The application/written request must contain the following information (refer to single line key diagram of the grid station): - Equipment nomenclature in the application (voltage level, control number, controlled equipment). - Equipment location (name of grid station). - Nature of maintenance work (routine, special, major or minor maintenance). - Dates and timings for work. Hereunder is given a specimen of the application/written request for arranging shutdown of an equipment. From: Senior Engineer/Dy. Manager 220 KV G/S NTDC, New Kot Lakhpat Lahore To: NPCC/RCC Islamabad/Jamshoro Subject: SHUT DOWN A shut down is required on 132 KV Circuit Breaker' KLP-4 controlling KLP-Saidpur circuit at New Kot Lak Pat Grid Station for the purpose of major overhauling of the circuit breaker. This shut down is required on dated _________ from _____ hours to ______ hours. Please approve the shut down and inform this office accordingly. Signature Copy to all concerned. The shutdown has been approved and you have been informed, now get PTW and start work. 4. Procedure for Issuance of PTW The following steps should be followed for getting PTW:- Ask the shift engineer or shift in charge station operator to issue a PTW on the concerned equipment in your name. - Station operator after his satisfaction will isolate the equipment to be going under PTW through local or remote switching operations - If applicable he will provide PTGs on the equipment or will ask you to provide PTGs before starting work. - He will write the nomenclature of the equipment on which it is safe to work on front page of the PTW (upper column). - He will also write (lower column) where and on which points he has installed PTGs or ask you to do the same. - He will put his signature at the specific space and ask you to receive your copy of PTW. - You must read the entries made by station operator in his portion (front page of PTW) and verify that equipment nomenclature, isolation points and matter of the PTGs are clear and correct. (refer grid station single line key diagram). - Then write your name, designation, date, time in front column of backside of the PTW, put your signature and receive your copy. 4.1. Return PTW after doing the Job - After completion of the maintenance work wind up your T&P and local safety precautions (barriers, caution tags etc.) - Remove PTGs. - Ask the station operator to put caution notice (reference copy attached) duly filled and signed by him, on the control switch of equipment mentioned in PTW. - Tell your crew to stay clear of the equipment because now it is no more safe to work on. CAUTION NOTICE Caution notice is also a legal document of WAPDA/PEPCO which is to be put on controlling switch-gears, switching in those the equipment under PTW can become live. - Go to Control Room and fill up second column (clearance certificate) of backside of PTW. Now the equipment, which was under PTW, is ready from your side for putting in service. CAUTION TAG Caution tag is also a type of caution notice but it has no legal value. This can be in any form of a warning sign to be put on the auxiliary supply control. switches. In our system isolation switches on auxiliary supplies (AC, DC, CT, PT supply, etc.) are not provided normally in the equipment local control cubical but in control room building, so in case the isolation of these supplies is required ask the operator also to put caution tags on these switches. 4.3 Cancellation of PTW - Now go at equipment site, have a walk around from ground level and check isolation points carefully and verify that these are as mentioned in PTW, otherwise have them corrected by the issuing authority. - After having your complete satisfaction of isolation and of your crew, install PTGs at the desired points, - Put barrier around the work area and caution tags at the requisite locations. Barrier may be a physical one or warning signs. - Perform the maintenance work. - Now the station operator after his satisfaction will cancel the PTW by making entries in third column. - Station operator will remove caution notices after getting your signature therein and making other - entries in caution notices. PTW (Permit to Work) Specimen NATIONAL TRANSMISSION AND DESPATCH COMPANY LTD PERMIT-TO-WORK It is safe to work on the following apparatus which is dead, isolated from all live conductors, and is earthed. All other parts are dangerous. _____________________________________ ________________________ 3.___________________________________ __________________________ _____________________________________ ________________________ State below exactly the apparatus on which it is safe to work: Signature: ___________________Designation: _______________________ 1. _____________________________________ _______________________ Date ________________________Time ________________________(Hrs) PTO _____________________________________ ________________________ 2. _____________________________________ _______________________ _____________________________________ ________________________ 3. _____________________________________ _______________________ _____________________________________ ________________________ State below exactly at what point (s) the apparatus is connected to earth: 1.___________________________________ __________________________ _____________________________________ ________________________ 2.___________________________________ __________________________ (Back side of PTW Form) RECEIPT OF CLEARANCE This form after being signed for the work to proceed must be retained by the authorized person in charge of the work until the work is suspended or completed. I hereby declare that I am the authorized person in charge of work, for which the apparatus mentioned hereon has been made dead. Signature_______________ Designation __________________________ Date ____________________ Time _________________Hrs)_____________________________________ _________________________ RETURN OF CLEARANCE The apparatus mentioned hereon must not be again made live until this Form has been signed and returned by the authorized person in charge of the work. In case where more than one Permit-to-Work has been issued for the same apparatus, it must not be again made live until all forms have been signed and returned by all the authorized persons in charge of the work. I hereby declare that all men under my charge have been withdrawn and warned that it is no longer safe to work on the apparatus specified in this Form, and that gear, tools, temporary earth connections are all clear, leaving that portion of the apparatus upon which my men have been working ready for placing into commission. Signature______________ Designation __________________________ Authorized person in charge of the work Date _____________________ Time _______________________(Hrs) _____________________________________ _________________________ CANCELLATION OF CLEARANCE. TO MAKE IT LIVE WILL KILL THEM No: ___________ Aerial Line _____________________________________ ______________ Electrical Apparatus _____________________________________ _______ Working party in charge ____________________designation ____________ (name) This Caution Notice placed on controlling switchgear at ________________ (time) on ________________ (date) I hereby declare this Form cancelled Signed by Shift In charge Signature__________________ Designation ________________________ Date ________________________ Time _______________________(Hrs) Note: This Form, duly completed, must be kept for record by the RE/AE/AM according to instructions. Work being done _____________________________________ __________ Caution Notice Specimen NATIONAL TRANSMISSION AND DESPATCH CO LTD. This Caution Notice removed from the controlling switchgear in the presence of _______ _____________________________________ _________________________ (name) In charge of the, working party at _____________________ on __________ (time) (date) Signed by In charge working party Designation _____________________ CAUTION MEN WORKING ON THIS APPARATUS Signed by Shift In charge TSG NTDC P&I SKILLS The application of portable temporary ground (P.T.G) to isolated electrical UPGRADING TRAINING PLAN 6. PORTABLE GROUND (P.T.G) TEMPORARY OBJECTIVE You will apply/remove Portable Temporary Grounds (P.T.G) on/from isolated, electrical equipment following the procedure given and observing the safety precautions. equipment in preparation for work is a most important safety practice. P.T.Gs provide essential safety not only to the worker but also to the equipment, so it is important that the reasons for grounding an electrical equipment are well understood. Grid maintenance work is always performed on electrical equipment with the equipment in isolated and grounded state. Grounding of the equipment to be worked upon is accomplished by installing portable temporary grounds on both or all sides of the supply sources. P.T.Gs provides a low resistance power circuit between the electrical equipment and station ground mesh. If due to an accident or by mistake the equipment being worked on is energized, then the P.T.Gs provide a high capacity, low resistance circuit between phases and station ground if they are used correctly. The P.T.Gs maintains this circuit until the primary or back up protection relaying senses the fault and disconnects the power source. 2. Protection Provided by Properly Installed P.T.Gs The following protections and safe conditions are automatically achieved if P.T.Gs are provided on the input and output connection sides of the equipment to be worked upon: - Positive proof of isolation Drain of (Electromagnetic potentials) 1. Introduction induced potentials and Electrostatic - Guards against the danger of accidental energization of the equipment being worked on - Ensures that non-current carrying metallic parts of equipment remains at ground potential 3. Fittings and Accessories of P.T.G Set Grounding Cables: A PTGs set has 3 separate grounding cables. The length of cable may vary according to the requirement but must not exceed 15 feet in length. 4/0 AWG (13.46 mm diameter) stranded extra flexible copper cable is recommended to be used as a P.T.G. cable when fault currents are less than 34000 amps. 2/0 AWG stranded extra flexible copper cable can be used when the fault currents are less than 22000 amps. The jacket or cover of the cable is only to protect the copper strands from mechanical damage and should not be relied upon for insulation purpose. Ground-End Clamp: The "Tee" handle clamp is the most commonly used groundend clamp. Line-End Clamp: The most commonly used line end clamps are "All Angle Clamp" and "C Clamp”. Both the "groundend" and "line-end" clamps must have the same current rating as of the grounding cable. Grounding Stick: An approved epoxy stick or any other insulated stick is used to apply and remove P.T.Gs. 4. Procedure to Apply PTGs A thumb rule to apply P.T.Gs is: GROUND-END CLAMP MUST BE ATTACHED TO THE STATION GROUND SYSTEM FIRST AND TAKEN OFF LAST - Check the P.T.Gs hardware (cables, clamps) and grounding stick for good condition. - Physically check and verify the isolation of the electrical equipment to be worked on with an approved tester or by an approved method e.g. line teasing. - Select a suitable ground conductor and clean it with wire brush to remove corrosion if any. - Apply ground-end clamp at the cleaned ground conductor. The clamp jaws must fully cover the conductor and be tight. Note. If installation of ground-end clamp on station ground conductor is not possible directly, then copper stirrups made of 4/0 solid copper can be used at that particular location. - Lay down the grounding cable on the ground, fix up line end clamp into the grounding stick hook and tight it fully. - Open the line-end clamp jaws enough to be put on the line conductor. - Lift holding on only to the ground stick to a vertical position. Get assistance from a second person with a ground stick if necessary - With a firm grip of your hand on stick raise it up and put the line-end clamp on the line conductor by adjusting the jaw opening of clamp so that it fully covers the line conductor. Tighten the line-end clamp by rotating the stick anti clockwise. Before tightening it fully, turn it around the conductor to remove corrosion, otherwise the line conductor should be cleaned with line end wire brush before applying P.T.Gs line-end clamp on it. - In the same way apply the remaining P.T.Gs. - After having the P.T.Gs been applied, the grounding cables should not be allowed to swing but should be tied to the structure and fastened with a nylon rope. 5. Procedure to Remove P.T.Gs A thumb rule to remove PTGs is: WHILE REMOVING P.T.G.s, FIRST REMOVE LINE-END CLAMP AND THEN REMOVE GROUND-END CLAMP - Untie the wrapped/fastened ground cables. - To remove P.T.Gs, fix up ground stick hook in to line-end clamp and rotate the stick clockwise until the line conductor is fully released. Then take off the clamp and lower it to the ground gently. Take off the grounding stick from line-end clamp. - In the same way remove all the line-end clamps. - Then take off all the ground-end clamps. - Coil all the P.T.Gs and tie each coil with a piece of nylon rope. 6. Safety Precautions for Handling P.T.Gs - While applying and removing P.T.Gs, safety shoes, hard hat, eye protection flash goggles and leather gloves must be worn. - Avoid touching the ground cables when installed. - In damp or wet weather insulated rubber gloves must be worn while applying and removing P.T.Gs. - Grounding stick must always be inspected for good condition before use and held away from body while in use. - Potential testing on the equipment concerned should be performed before applying P. T. Gs. This can be done by using approved potential testers, or by touching the line conductor wish the metallic head of grounding stick and then slowly removing it. If a potential is present a "buzzing sound" will be heard. This is known as "teasing" a circuit. Potential testing is necessary while applying P.T.Gs in gas insulated switchgears (GIS). - Some high voltage circuits may appear to be live when teased due to induced potentials. - It is not necessary to test for any electrical potential when the equipment is obviously isolated. - Safe limits of approach must always be considered while applying and removing P.T.Gs. m 3 5 2 0 0 S i o 6 2 0 S 3 0 L 1 1 1 1 1 1 1 1 1 r = i O Z 2 0 L 3 P U B L I C A T I O N