BIFM Briefing 2 - Permit to Work Systems

advertisement

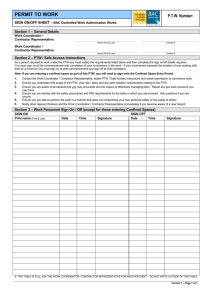

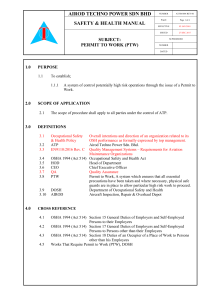

BIFM Briefing 2 April 2009 Safe operation of permit to work systems Background & industry problems Originally, the Permit to Work (PTW) system was developed as a formal written document to control high hazard activities associated with the petroleum, chemical and allied industries. The use of PTWs has expanded and they are now being used in a diverse range of industries and situations. However, unfortunately and all too often, PTWs are being used inappropriately or ineffectually. Numerous accident investigations have identified that, far from controlling the risks arising from workplace activities, poorly conceived and implemented PTW systems are creating complacent attitudes that risks are somehow controlling themselves, merely because they may have been identified. What is going wrong? More and more situations have arisen where organisations issue PTWs in place of visitor access passes for contractors carrying out work within their premises, regardless of whether their activities are high risk, or not. This, coupled with inadequate or nonexistent training, has, in many instances, had the effect of grossly devaluing attitudes to and the usefulness of permits. There has often been a failure to recognise that the issue of a permit does not by itself make a job safe. If you need to keep an audit trail of contractors entering your premises then consider use of an ‘Authority to Work’ form. This can include many of the elements you may require to satisfy your internal or client-led procedures. The danger of the inappropriate use of Permits to Work is the establishment of a ‘False Security Blanket’, with many organisations wrongly believing that by insisting upon the issue of PTWs they are doing all that is required of them to demonstrate their efforts to control risks. Effective training There is no requirement within health and safety law to operate PTW systems, although they can form an essential part of safe systems of work for many maintenance activities. If you are going to use PTWs, however, your PTW system must be designed to ensure that proper consideration is given to the risks of a particular job and the permit itself must be a sufficiently detailed document which authorises certain people to carry out specific work at a specific place at a certain time, and which sets out the precautions needed to complete the job safely. Effective training is the necessary foundation for the successful implementation of a PTW system. Those who issue permits must be sufficiently knowledgeable about the hazards and precautions associated with the proposed work; they must be able to ask enough “what if” questions to enable them to identify all potential hazards. Employees and contractors who work under permits must fully understand the importance of the PTW system and be trained in its use. Above all, once a permit has been issued, regular monitoring must be carried out to ensure work is being carried out as planned. Deviation from the agreed methodology without recourse to the permit issuer has often been identified as the cause of accidents. If you are operating a PTW system on behalf of a client (contractor FM situation) then ensure you have enough info and authority to run system effectively. Check that: The job is a High Risk activity and warrants a permit. A Permit to Work System may be needed: Whenever it is intended to carry out work which may adversely affect the safety of personnel, plant or the environment Non-production work Non-routine operations Co-ordination of 2 or more individuals / groups Where there is a transfer of work / responsibility A Permit to Work System must not be used for: The control of general visitors to site Routine maintenance tasks in non-hazardous areas The control of contractors / sub-contractors for the above category of work A Permit to Work: is a “Formal recorded process” for HIGH RISK activities is the highest level of control for HIGH RISK activities must be monitored, audited and reviewed must not be used to control contractors/sub-contractors for anything other than HIGH RISK activities. The issue of a PTW does not, by itself, make a job safe Further information may be obtained from the HSE website at www.hse.gov.uk The BIFM acknowledges the support and contribution of the HSE and GSH in the preparation of this Briefing. Disclaimer Although great care has been taken in the compilation and preparation of this briefing, the BIFM cannot in any circumstances accept responsibility for errors, omissions or advice given. About the British Institute of Facilities Management The BIFM is the ‘natural home’ of facilities management in the UK. Founded in 1993, the Institute provides information, education, training and networking services for over 12,000 members – both individual professionals and organisations. The Institute is inclusive, working across related disciplines and forming alliances with like-minded professional bodies. Increasingly international in outlook, the BIFM is a founding member of both EuroFM and Global FM. BIFM’s members are responsible for many of the services that support business and other organisations, including business continuity, health & safety, space planning, energy management, maintenance and catering. For more information visit www.bifm.org.uk or telephone 0845 0581356.