Chapter 6 Water Carriers

advertisement

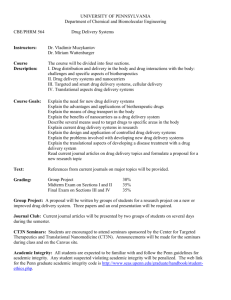

Chapter 6 Water Carriers Water Transport Industry Overview Significance of Water Transport Water transportation remains a viable mode of transportation for the movement of products and especially basic raw materials. Domestic water carriers compete with railroads for the movement of bulk commodities (such as grains, coal, ores, and chemicals) and with pipelines for the movement of bulk petroleum, petroleum products, and chemicals. Types of Carriers Like motor carriers, the first major classification of the domestic water carrier industry is between for-hire and private carriers. A private carrier cannot be hired and only transports freight for the company that owns or leases the vessel. Private water carriers are permitted to transport, for a fee, exempt commodities (commodities not under government regulation); when they are hauling such exempt goods, they are technically exempt for-hire carriers. Regulated water carriers are classified as either common or contract carriers. Carriers that operate over the inland navigable waterways are classified as internal water carriers. Internal water carriers use barges and towboats. Coastal carriers operate along the coasts serving. Intercoastal carriers transport freight between East Coast and West Coast ports via the Panama Canal. Competition The major water carrier competition is with two other modes, namely rail and pipelines. Water carriers compete with railroads for the movement of dry bulk commodities such as grain, coal, and ores. Because the cost of the water-rail combination is lower than the all-rail route, shippers continue to request the combined water-rail service. Water carriers and pipelines are vigorous competitors for the movement of bulk liquids (petroleum and petroleum products). To a very limited degree, water carriers compete with trucks. However, trucks are usually used to overcome the accessibility constraints of water carriers because trucks tie inland areas to the waterways for pickup and/or delivery. Operating and Service Characteristics COMMODITIES HAULED AND RELATED CHARACTERISTICS Water carriers are important for low-value, bulk movements of liquid and dry materials. The low rates of water carriers are attractive to the shippers of such commodities. Water carriers are considered to be medium-to-long-haul carriers. Their carrying capacity is relatively large, which makes short hauls with frequent stops uneconomical. A 1,500-ton load represents the typical carrying capacity of 15 railcars or about 50 trucks. The long hauls and the large carrying capacity combined with fuel efficiency allow water carriers to offer low-cost service—about 72 cents per ton-mile on average. The low cost of the water carrier comes with some service disadvantages that need to be considered by shippers. Water carriers are relatively slow. The limited accessibility of the water carrier usually necessitates pickup or delivery by another mode of transportation to bridge the accessibility gap. The transfer between modes will obviously add to the total cost. Overall, water carriers are an attractive alternative for low-value traffic, where transportation rates are a significant part of the total delivered cost and price of the good. However, the poor service characteristics may add cost for the user, which has to be traded off against the low rate to calculate the true total cost. Equipment TYPES OF VEHICLES Because most domestic water carriers transport bulk materials, they use ships with very large hold openings to facilitate easy loading and unloading. Watertight walls dividing the holds allow a ship to carry more than one commodity at a time. However, most carriers will carry a limited variety of products at one time. The largest ship in the domestic water carriage industry is the tanker. A tanker can carry anywhere from 18,000 to 500,000 tons of liquid, generally petroleum or petroleum products. Due to oil spill problems, the use of double-hulled tankers has become preferable to the use of the more conventional single-hulled tankers. Another type of vessel is the barge, a powerless vessel towed by a tugboat. Barges are most commonly used by internal waterway carriers. TERMINALS Water carrier terminals are often provided by the public. Most ports are operated by local government agencies, and many ports have publicly operated storage facilities. Some volume users of transportation invest in and operate port facilities or shipper run terminals. Individual firms that handle such commodities as grain, coal, and oil commonly build docks, terminals, and commodity-handling facilities to meet their unique needs. The water carriers have the opportunity to use these private facilities owned by shippers. Over the past few decades, major port improvements have centred on the mechanization of materials-handling systems, especially for internal waterway ports. Efficient handling of larger volumes of bulk commodities has been a prerequisite for ports that desire to remain economically competitive with other ports along the waterway and for water carriers that seek to be competitive with other modes. The port facilitates ship loading and unloading, which means that the port must be equipped with cranes, forklifts, and other handling equipment. Certain commodities like oil, grain, and coal require more technically advanced loading equipment, such as pneumatic loaders and railcar dumping equipment. Such materials-handling equipment reduces unproductive port delays and enables water carriers and ports to remain economically viable. The port also facilitates the transfer of freight from one mode to another. The port is usually served by railroads and motor carriers. Terminals at the port will have railroad sidings to handle inbound and outbound rail freight as well as parking lots for motor carrier equipment. Ports play a key role in promoting the efficiency of intermodal transportation. Because barges and ships carry larger loads than rail or motor carrier vehicles, storage facilities are necessary at the port. The storage areas receive cargo from many trucks and railcars. This freight is held until sufficient volume is obtained to be handled effectively by barge or ship. Conversely, when a loaded vessel arrives at port, the freight is unloaded, stored, and then dispatched in hundreds of railcars or trucks at some later date. Cost Structure FIXED VERSUS VARIABLE COST COMPONENTS The basic cost structure of water carriers consists of relatively high variable costs and low fixed costs. Like motor carriers and air carriers, water carriers do not provide their own highways (rights-of-way). The waterways are provided by nature (except canals) and are maintained, improved, and controlled by the government. The carriers pay user charges—lock fees, dock fees, fuel taxes—for the use of government- provided facilities. These user charges are directly related to the volume of business, and therefore, are considered variable costs. The operating costs for water carriers are approximately 85 percent variable and 15 percent fixed. Fixed costs include depreciation and amortization, and general expenses. The major variable expenses are line-operating costs, operating rents, and maintenance. Line-operating costs are those expenses associated with renting operating equipment and facilities. INFRASTRUCTURE As indicated above, the domestic water carrier’s low fixed costs can be attributed in part to public aid in the area of infrastructure. For water carriers, the major public aid is the construction and maintenance of waterways. LABOUR Water transportation is not labour-intensive. In 1997, 2.72 million ton-miles of freight were transported for each water carrier employee. This compares to 4.74 million ton-miles for each rail employee, 0.4 million ton-miles for each motor carrier employee, and 39.3 million ton-miles for each pipeline employee. Labour is required at the terminal to load and unload general commodities. The freight is moved from the dock onto the ship and into the appropriate hold for the voyage (and vice versa for unloading). In addition, labour is required to handle the loading of freight from connecting modes, such as truck and rail, and to store the freight waiting to be loaded onto the ship or connection carriers. CURRENT ISSUES DRUG AND ALCOHOL ABUSE PORT DEVELOPMENT Because of today’s environmental concerns, ports are having trouble keeping pace with the accelerated developments in global trade. Ports are now having to balance competitive economic concerns with the concerns of the public, which, rightly or wrongly, often view ports as a main source of air, water, and noise pollution. Also, a current issue facing North American ports is the growth of multicarrier alliances, leading to the expansion of the already gigantic ships. An increase from 6,000 20-foot equivalent units (TEU) (refers to container size) to 8,000 TEU’s has many ports worried for the future. The larger the ships are, the deeper they go, meaning that many of the smaller ports will need to begin the dredging process as soon as possible to be able to compete in the future. The dredging process would allow ports to make their waterways deeper and wider in order to accommodate these new, larger ships and allow them to stay competitive.