Lab Report

advertisement

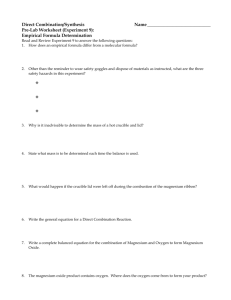

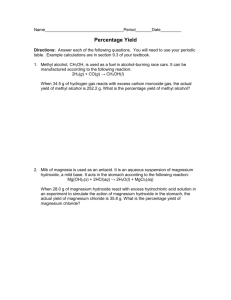

By: Steve Bintz, Katie Jones, Tyler Babbie Lab Report Steve Bintz Katie Jones Tyler Babbie Section 4 Team 4 Project 2: Potter’s Potions Predicament November 7, 2005 Abstract (Experimental Summary) The purpose of this experiment was to synthesize a small amount of magnesium acetate for Potter’s “Confusing Concoction” through and acid-base reaction. It was determined that the best method to remove the salt from the water, produced by the reaction, was to heat the solution until only a solid remained. In addition, a simple anion and cation test was done on the solution to confirm the presence of the correct materials. Also, the effects of limiting reagents were evaluated by varying the amounts of chemicals used. The percent errors were acceptable because the highest was 23.1%, while percent yields were high with the lowest being 77%, suggesting the experiment was a success. The errors came about from overheating and one major miscalculation in the proposal stage of the lab. This calculation error caused too much product to be produced, specifically, 3.662g, during one of the limiting reagent reactions, but nonetheless produced a very close amount to the theoretical value. It was confirmed that the solid which was produced was indeed magnesium acetate by proving the anion and cation presence. It can be concluded that the experiment was a success. Proposal Notebook Report Peer review (20) (15) (55) (10) Total 1 By: Steve Bintz, Katie Jones, Tyler Babbie I. Introduction Harry Potter wants to get extra credit in his potions class. In order to receive the credit, he must synthesize the primary ingredient in one of many possible potions. Team four, who had previously made Professor Snape suspicious, was chosen to help Harry make about two grams of magnesium acetate. This is the main ingredient in a potion which reminds everyone who drinks it of lemonade. However, because the team has peaked the Professor’s interest, they must also prove that the synthesis actually produces the necessary product by performing purity tests. An acid-base reaction is one which, when completed, produces a salt and water. The key is whether the salt which is produced is soluble in water. If it is not, then a precipitate will be produced, meaning what a solid will appear, but if it is, then the salt will be suspended in the water. It is important to know which is the case before the experiment is started in order to devise a method to extract the salt, which is the desired substance, from the water it’s in. Here, the magnesium acetate was soluble in water, which means the water had to be boiled off in order to obtain the product. In this experiment, it is very important to have very precise and accurate calculations. Examples of how to determine the experimental mass of product produced can be found in Appendix A. Here, the exact theoretical amount of magnesium acetate which was to be produced can be found. This number is based on the amounts of the raw ingredients used. II. Experimental The experiment commenced after having determined the correct chemicals to produce the desired magnesium acetate along with the balanced chemical equation for the reaction. In the experiment, magnesium hydroxide and 1M acetic acid were mixed in pre-determined ratios based on stoichiometry from the chemical equation. After mixing the ingredients together, the liquid was divided into two evaporating dishes and covered with watch glasses. These materials were previously massed in order to determine the total change in mass at the end of the experiment. Next, these were placed onto hot plates and heated until a solid had formed. It was important here to keep close watch of how much liquid was left since it would be detrimental to burn off any product. After making the decision that the liquid had been boiled off. The materials were cooled and weighed. After recording the mass, they were reheated for a short time and subsequently weighed. This was done until constant mass had been achieved within 0.005g. To demonstrate the effects of limiting reagents, the same process was used except different masses of starting substances were used. To show the acetic acid as the limiting reagent, more magnesium hydroxide was used. To confirm magnesium hydroxide as the limiting reagent, more acetic acid was placed into the solution. The key here is that, after heating, it was demonstrated that still only the expected amount of magnesium acetate was produced, not more. In order to ensure that the product was in fact magnesium acetate, it had to be determined first if the magnesium cation and acetate anion were present. To do this, two different purity tests were used, one which tested for the presence of the cation and one 2 By: Steve Bintz, Katie Jones, Tyler Babbie for the anion. Both tests were conducted on the mixture immediately after the original ingredients were mixed and before any heating. It was confirmed that both the necessary cation and anion were present, which proves that magnesium acetate was produced through this synthesis and nothing else. III. Results and Discussion The results of this experiment can be found in the following tables. Table 1 summarizes the results for the “perfect” synthesis, table 2 summarizes the results of reagent #1, and table 3 summarizes the results of reagent #2. Sample calculations of this data can be found in Appendix A. 2HC2H3O2 + Mg(OH)2 2H2O + Mg + 2C2H3O2 2H20 + Mg + 2C2H3O2 heat> 2H20 (g) + Mg(C2H3O2)2 Table 1-Perfect Synthesis= 68.3ml of 1M Acetic Acid, 0.820g Magnesium Oxide Mass of Mass of evaporating Mass of evaporating Powder/Precipitate evaporating dish dish, watch glass, and dish, watch glass, and Mass (g) and watch glass (g) solution before powder: after heating (g) heating (g) Part 1 60.08g 99.05g 61.07g 0.99g Part 2 57.51g 88.57g 58.06g 0.55g TOTAL: 1.54g Table 2-Reagent #1= 68.3ml of 1M Acetic Acid, 1.500g Magnesium Oxide Mass of Mass of evaporating Mass of evaporating Powder/Precipitate evaporating dish dish, watch glass, and dish, watch glass, and Mass (g) and watch glass (g) solution before powder: after heating (g) heating (g) Part 1 56.914g 91.959g 58.571g 1.657g Part 2 63.035g 97.982g 64.726g 1.691g TOTAL: 3.348g Final precipitate mass is off due to incorrect calculations in the proposal phase of this experiment. The incorrect calculations are shown on Appendix A, along with what was supposed to be the correct calculations. Part 1 Part 2 TOTAL: Table 3-Reagent #2= 74.8ml of 1M Acetic Acid, 0.820g Magnesium Oxide Mass of Mass of evaporating Mass of evaporating Powder/Precipitate evaporating dish dish, watch glass, and dish, watch glass, and Mass (g) and watch glass (g) solution before powder: after heating (g) heating (g) 56.999g 93.261g 57.940g .941g 63.078g 100.230g 63.078 .76g 1.70g Table 4- Percent Yield 3 By: Steve Bintz, Katie Jones, Tyler Babbie Perfect Original Reagent # 1 Actual Reagent #1 Reagent #2 Percent Yield 77% 1.67x 10^2 % 91.42 % 85% The method used in the experiment was an acid base reaction. For this experiment, mixing aqueous magnesium hydroxide with acetic acid yields water and aqueous magnesium and acetate ions. The water is removed by boiling. As the water is removed, the magnesium and acetate ions bond to form magnesium acetate. Solving for the limiting reagents, we found that we would need 68.3 ml 1M acetic acid and 0.82g of magnesium hydroxide. This is the pair of reactions utilized: 2HC2H3O2 + Mg(OH)2 2H2O + Mg + 2C2H3O2 2H20 + Mg + 2C2H3O2 heat> 2H20 (g) + Mg(C2H3O2)2 The results show that the “perfect” synthesis of 2.00 grams of magnesium acetate was indeed not perfect, but instead 1.54g, which is shown in Table 1 and is a difference of .46g. Thus, this experiment basically consisted of heating the liquid acetic acid out of the solution: hence, forming the powder magnesium oxide precipitate. Then, the results from Reagent #1 were also off, but more so than the others. This is shown in Table 2 when the final experimental precipitate mass was 3.348g, which is much larger than the intended 2.00g of magnesium acetate, by a difference of 1.35g. This difference is due entirely to miscalculations in the beginning of this experiment when it was decided how much of what, to use, in order to get the correct answer of acetic acid being the limiting reagent. This is shown in the sample calculations in Appendix A when it turned out that the magnesium oxide was the limiting reagent instead of the acetic acid, which was the entire purpose of this part of the experiment. Furthermore, it is also shown through these calculations that in order to get the result desired, in order to prove that the acidic acid was the limiting reagent, 4.86 g of the solution Mg(C2H3O2)2 should have been made originally. Basically, this means that there wasn’t enough magnesium oxide used, or less acidic acid could’ve been used. Next, the results from Reagent #2 showed to be the most accurate of the three various parts. This is shown in Table 3 as the final precipitate mass is 1.70g, the closest of the three to the objective 2.00g. Although there is some error in this part of the experiment, it still shows that the magnesium hydroxide is the limiting reagent because the acetic acid will be in excess and the magnesium hydroxide will not allow more to be made. Two tests were performed to determine the purity of our magnesium acetate. The first was using a flame test to check for magnesium. The procedure detailed in the handout was followed. Dipping our nichrome wire into the aqueous solution of magnesium acetate and then holding it over a flame, no change was visible. This is characteristic of a magnesium cation. If the flame had changed, then the solution would be assumed to have been contaminated. The test for acetate was more involved. Following the procedure on the sheet, we put 2ml of our solution in a test tube. 1ml of ethanol was added to the test tube, followed by one drop of concentrated sulfuric acid. When this solution is then heated in a water bath, it gives off a fruity smell. The scent of fruit was indeed smelled by the experimenters as well as bystanders. Imperfections in the experiment lead to error. When boiling the water out of the solution, the bubbling solution occasionally dripped out of the evaporating dishes. Also, 4 By: Steve Bintz, Katie Jones, Tyler Babbie incomplete evaporation could lead to a heavier apparent mass of magnesium acetate than was actually there. Human error in calculation is potentially the biggest source of error in this project. A mistake in the calculation of the correct amount of acetic acid was a large mistake in the lab. This mistake probably happened when in molar mass calculations. Calcium magnesium acetate is used as an environmentally friendly alternative to sodium chloride road salt used to de-ice roads. It is less toxic to organisms in water and on land (McFarland). Our method synthesizes magnesium acetate, a major component of calcium magnesium acetate. It does this using no dangerous chemicals. Using the acidbase reaction to produce magnesium acetate would be a safe way to produce alternative road salt. Percent yield is the actual yield divided by the theoretical yield and multiplied by 100 %. In this experiment, the percent yields are particularly important because it is an indicator of how efficient the experiment was in each of the three different parts. Furthermore, the results in this experiment for percent yield are shown in Table 4 and Appendix A. The results in Table 4 show that if the calculations were again correct in the proposal, then the reagent #1 would have the highest percent yield of 91.42%. However, this is not the case. Hence, excluding reagent #1 because of its inaccuracy, reagent #2 was the most accurate and has the highest percent yield of 85% and the “perfect” synthesis is close behind with a 77% yield. IV. Conclusions The experiment concludes that it is possible to synthesize predetermined masses of magnesium acetate in an acid-base reaction by controlling the limiting reagents. For example, when 0.82g Mg(OH)2 is used with our experimental procedures, there will be about 1.5-1.8 g product. It is not possible to synthesize exactly 2g of this product using our experiment and lab procedure. Cation and anion tests prove that our synthesized product includes both magnesium and acetate. If this experiment were to be done again, the procedure could be improved. More attention to the preliminary calculations would remove much of the error in this lab. A better device to evaporate the water from the magnesium and acetate solution would be better than the evaporation dishes with watch glasses, or perhaps splitting the solution three ways would have reduced spilling. V. References McFarland, B.L.; O'Reilly, K.T., Environmental Impact and Toxicological Characteristics of Calcium Magnesium Acetate, 1992. IN: Chemical Deicers and the Environment. Lewis Publishers, Boca Raton, Florida. p 194-227. 9 fig, 6 tab, 50 ref. http://md1.csa.com/partners/viewrecord.php?requester=gs&collection=ENV&recid=9306 831&q=environmental+impact+of+magnesium+acetate&uid=786974874&setcookie=yes [accessed: November 5, 2005] 5 By: Steve Bintz, Katie Jones, Tyler Babbie Appendix A - Sample Calculations Katie Jones Precipitate mass = (1) [Evaporating dish, watch glass, and precipitate mass (g) - evaporating dish and watch glass mass (g)] = 58.571g-56.914g= 1.657g = (2) [Evaporating dish, watch glass, and precipitate mass (g) - evaporating dish and watch glass mass (g)] = 64.726g-63.035g= 1.691g Total = (1) [Evaporating dish, watch glass, and precipitate mass (g) - evaporating dish and watch glass mass (g)] + (2) [Evaporating dish, watch glass, and precipitate mass (g) - evaporating dish and watch glass mass (g)] Total= (1) precipitate mass- (2) precipitate mass = 1.657g + 1.691g = 3.348g ***Due to incorrect calculations in the proposal portion of this experiment, the rectified calculations will be provided below, along with the original to show the mistakes made. Original % error =│(experimental value – true value)│ x 100% true value =│3.348g-2.00g│ x 100% = 67.5% error 2.00 Original Limiting Reagent #1 2HC2H3O2 + Mg(OH)2 2H2O + Mg + 2C2H3O2 1M, 68.3ml 1.5g 68.3ml HC2H3O2 x 1 mol x 1 L x 1 mol Mg(C2H3O2)2 x 142.398g = 4.86g L 1000ml 2 mol HC2H3O2 1 mol Mg(C2H3O2)2 1.500g Mg(OH)2 x 1 mol x 1 mol Mg(C2H3O2)2 x 142.398g = 3.662g Mg(C2H3O2)2 58.326g 1 mol Mg(OH)2 1 mol Original % Yield= Actual yield x 100% Theoretical yield = 3.348g x 100% = 1.67 x 10^2 % yield 2.00g Actual % error =│(experimental value – true value)│ x 100% true value 6 By: Steve Bintz, Katie Jones, Tyler Babbie =│3.348g-3.662g│ x 100% = 8.58% error 3.3662 Actual % yield = Actual yield x 100% Theoretical yield = 3.348g x 100% = 91.42 % yield 3.662g Steve Bintz 74.8mL HC2H3O2 │ L │ mole │mole Mg(C2H3O2)2│58.32 g Mg(C2H3O2)2 = 2.18g │1000mL │ L │ 2 mole HC2H3O2 │mole Mg(C2H3O2)2 .82 g Mg(OH)2 │ mole Mg(OH)2 │mole Mg(C2H3O2)2 │ 142.40 g Mg(C2H3O2)2 = 2.00g │58.32 g Mg(OH)2 │ mole Mg(OH)2 │ mole Mg(C2H3O2)2 Percent Yield = Actual Yield x100 Theoretical Yield Actual Yield = Weight of dish and glass after heat – weight of dish and glass before Actual Yield = (57.940g – 56.999g) + (63.838g – 63.078g) = 1.7g Theoretical Yield = 2.00g (as calculated above through stoichiometry) Percent Yield = 1.7g x 100% = 85% 2.00g Percent Error = | experimental value – true value| True value x 100% Percent Error = | 1.7 – 2.00| x 100% = 15 % error 2.00 Tyler Babbie 63 ml 1M HC2H3O2 x 1L/1000ml x 1 mol Mg(C2H3O2)2 / 2 mol HC2H3O2 x 142.398g Mg(C2H3O2)2 / 1 mol Mg(C2H3O2)2 = 4.8g Mg(C2H3O2)2 0.820g Mg(OH)2 x 1 mol Mg(OH)2 / 58.3295g Mg(OH)2 x 1 mol Mg(C2H3O2)2 / 1 mol Mg(OH)2 x 142.398g Mg(C2H3O2)2 / 1 mol Mg(C2H3O2)2 = 2.002g Mg(C2H3O2)2 Mass of evaporation dish and watchglass set 1= 60.08g Mass of evaporation dish and watchglass set 2= 57.51g 7 By: Steve Bintz, Katie Jones, Tyler Babbie Mass of set 1 and solution= 99.05g Mass of set 2 and solution= 88.57g Mass of set 1 after water is boiled out= 61.07g Mass of set 2 after water is boiled out= 58.06g Mass after heating- mass of evaporation dish and watchglass set= mass of magnesium acetate 61.07-60.08= 0.99g 58.06-57.51g=0.55g Adding the masses 0.99g+0.55g= 1.54g magnesium acetate Percent Yield = (Actual yield/Theoretical Yield) x 100 (1.54/2.002)x 100 = 76.92% yield Percent Error = ((Experimental – Expected)/ Expected) x 100 ((1.54-2.002)/2.002) x 100= -23.1% error 8