page5

advertisement

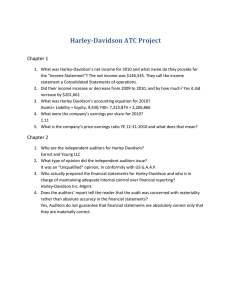

Harley-Davidson: Preparing for the Next Century " 906-410 Transforming Harley By 1980, with Harley's profitability down, AMF began looking for a buyer. Vaughn Beals, the then CEO, orchestrated a highly leveraged buyout with the help of a small group of Harley-Davidson managers. Able to raise only a small fraction of the $81 million buyback price, Harley-Davidson's top management took the rest on as debt. This debt forced Harley's new owners to pare down costs and cut back motorcycle production. Their goal was simple: survival. Benchmarking Honda To benchmark the company against Honda, senior managers visited Honda's Ohio plant in the United States. After touring the plant, Tom Gelb, the senior vice president for operations, recalled: "The [Honda] assembly line was neat and uncluttered—unlike our operation, where the line was always littered with parts and material. There was minimum paperwork and things flowed very smoothly."8 In the Honda plant, inventory was controlled through a just-in-time (JIT) system that used no computers or automation. Moreover, motorcycles were built to order rather than for inventory. This shocked Harley-Davidson executives, whose multimillion-dollar computerized inventory system at their York, Pennsylvania assembly plant required far greater amounts of buffer inventory for both work-in-process (WIP) and finished motorcycles. The computer-controlled inventory system Harley used had cost $2 million and moved inventory from storage to production via conveyors, which snaked over two miles within the plant. Jeffrey Bleustein, the senior vice president for parts and accessories, acknowledged: "[The Japanese] . . . were just better managers . .. and they understood how to do manufacturing a hell of a lot better, with less inventory and much higher quality."9 Beals concurred: "Harley-Davidson's production system was basically flawed. In this system, we gave the worker responsibility for quantity, not quality. Then we set up a whole police force for quality and a battalion of accountants to measure errors made in production."10 The differences between Harley-Davidson and Honda were striking. For example, only 5% of Honda's motorcycles failed to pass final quality inspection; over 50% of Harley's failed during the same test. According to Harley-Davidson's internal estimates, overall Japanese productivity was over 30% greater than at Harley-Davidson. According to a report by the Boston Consulting Group, Honda's value-added per employee was even better, on the order of two to three times that of its Japanese competitors, Suzuki and Yamaha. The Productivity Triad Beals and his management team realized that Harley's entire manufacturing system needed to be modified, and fast. Using Japanese production methods as a blueprint, top management teams formulated and implemented what they termed the productivity triad. This new approach involved (a) employee involvement, (b) use of JIT inventory practices, and (c) statistical operator control (SOC). ~ 8 Reid, Well Made, p. 4. 9 Ibid., p. 15. 10 Ibid., p. 18. -.