Guidance relating to use of Stabilizer P[...]

advertisement

![Guidance relating to use of Stabilizer P[...]](http://s3.studylib.net/store/data/008957957_1-d81c574c206bc3062859bc4196902229-768x994.png)

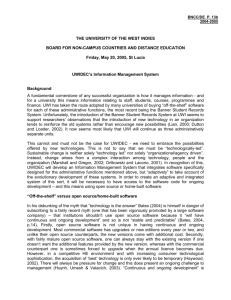

Guidance relating to use of Spreadsheet for calculating pad-size requirements Overview The spreadsheet is intended to assist users in determining minimum stabiliser foot/pad size requirements, based on a calculation of the lorry-loaders gross lifting moment (Ma) and subsequently the forces being placed through the stabilisers. The only cells which can be altered on this sheet relate to the essential information required for the lorry-loader being used, in terms of capacity and critical measurements etc. in the red cells on the right hand side; and the ground bearing capacity in the yellow bell (B:19) on the left hand side. This is stated in kN/m², although there is a small converter also on the sheet to convert from kN/m² to t/m² and vice-versa. The formulas used for calculating both the loader gross lifting moment (Ma) and the forces exerted through the stabilisers are as per the product standard BS-EN12999:2011; which have been available on ALLMI Guidance Note 013 – Stabilizer Forces, for approximately the last two years. The following sections provide guidance and/or a confirmation of the criteria to be entered in each of the lorry-loader boxes on the right-hand side of the spreadsheet. Loader Crane Data Maximum Hydraulic Radius – this is the maximum hydraulic radius of the loader crane being used for the lifting operation. The figure inserted in this box must be stated in metres i.e. 10.10. * Rated Capacity @ Max Radius – this is the maximum capacity corresponding to the radius stated above. The figure inserted in this box must be in kilogrammes i.e. 2,500 * *Note: it is common practice to insert the required radius and rated capacity for the specific lifting operation being planned as opposed to the maximum, with the aim of achieving a lower figure overall for the loader cranes gross lifting moment. This should only be done if it can be proven elsewhere within the lifting plan that suitable control measures are in place to ensure the radius and load stated are not exceeded. Radius of the CoG for deadweight of the Loader – this information should be obtainable from the manufacturer’s handbook and should be based on the measurement of the Centre of Gravity for the Loader in its “booms extended” configuration. The figure inserted in this box must be stated in metres i.e. 3.20. Dead Weight of the Loader Crane – this is again available from the manufacturer’s handbook or product range brochure. The weight inserted should be for the loader only (preferably excluding stabilisers) and not the GVW or kerb weight of the truck and loader. The value entered must be stated in kilogrammes i.e. 2,650. Establishing Forces Through Stabilizers Span of Crane Stabilizers – this is available from the manufacturer handbook and from the original stability test certificate plus any subsequent reports of thorough examination. The figure must be inserted in metres and is based on a measurement taken between the stabilizer foot centres in their fully extended position. Span of Auxiliary Stabilizers – If auxiliary stabilizers are fitted, information should be available as above. Again, the figure inserted must be in metres. Offset of Loader Crane Column – This figure should be available from the manufacturer handbook and/or the product range literature/sales brochure. The figure should be stated in metres and will typically range from 0.15 to 0.30 metres; although in some cases it could be significantly higher. Distance Aux Stabs from Crane Column – if auxiliary stabilizers are fitted, this information should be available from the original axle/stability calculations carried out by the manufacturer/installer. Again, this figure should be stated in metres as opposed to mm or cm. Once the above data has been inserted in the boxes on the right-hand side of the Spreadsheet, the stabilizer forces for the Loader (and Auxiliaries if fitted) will be displayed in both kN and tonnes in the boxes on the left-hand side of the sheet. The one remaining piece of data required for the user to input is the Maximum Permissible Load Bearing Capacity of the ground, which must be stated in kN/m². The table below gives some values for the load bearing capacity of various ground types. Once this is inserted, the sheet will calculate the minimum size of the pad required in m²; and on the right-hand side of the sheet at the bottom, it will also show the relevant minimum dimensions for both square pads and round pads. The pad must be strong enough to spread the stabilizer load over the full foundation area. Pad design calculations are required to ensure the pad has sufficient stiffness and strength to spread the load. Permissible pressure on the ground (load-bearing capacity of the ground) to DIN 1054 Filled ground, not artificially compacted 0Asphalt Established, evidently undisturbed ground 1 Mud, peat, marshy ground 2 Non-cohesive, adequately firmly established ground: Fine to medium sand Coarse sand to gravel Crushed stone compacted 3 Cohesive ground Mushy Soft Firm Half-solid Hard (solid) 4 Rock Weathered 100 kN/m² 200 kN/m² 0 kN/m² 150 kN/m² 200 kN/m² 250 kN/m² 0 kN/m² 40 kN/m² 100 kN/m² 200 kN/m² 300 kN/m² 100 kN/m² Disclaimer This note is for guidance only, it should be studied and the information applied with the assistance of expert advice as necessary. Every effort has been made to ensure the accuracy of the information provided, but no legal liability can be accepted by ALLMI for any errors or omissions, nor for any consequences thereof. The specifying of any safety factors and mat assembly configurations is the responsibility of the competent (appointed) person.