CL-07-02 Crane Lift Study Checklist

advertisement

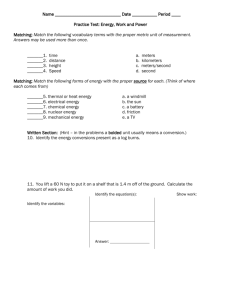

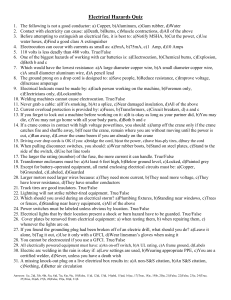

CRANE LIFT STUDY – CHECK LIST PROJECT NUMBER WORKS MANAGER DOCUMENT NUMBER Page 1 of 6 PROJECT TITLE SITE MANAGER DATE PROPOSED WORK METHODOLOGY WORK PARTY LOCATION DESCRIPTION REVIEW OF PROPOSED PROCEDURES & EQUIPMENT MANDATORY REQUIREMENTS HAZARD CONTROL MEASURE CHECKED Unidentified Job Specific Hazards JHA to be carried out by staff detailing on the day hazards that could not be practically assessed prior to attending site in addition to this “CHECK LIST”. All staff to sign on to JHA accepting this form and the on the day hazards and controls. JHA has been completed and approved by the relevant personnel in accordance with the JHA Procedure Hydro Hazards-Lack of awareness of local asset and other simultaneous operations Unlisted Specific Lift Hazards Works Manager to notify work party of ALL Hydro Tasmania Assets in area (including Protection PLC, Mechanical, Electrical and Civil Assets). Work party to inspect and make safe No crane works are to take place until the lift study has been completed in full Riding load or hook is prohibited Load never lifted over workers or plant Unknown Crane Type Unknown Crane Owner Unknown Capacity Unknown Crane Driver / Operator Unknown Rigger(s) Ticket No Unknown Designed Lifting Points Ensure design drawings and or Maintenance Manuals are available that designate / specify correct and certified lifting points and their designed lifting capacity Ticket No(s) DOCUMENT REFERENCE: CL – 07 – 02 REVISION: 4 HYDRO-285-68 DATE: 19/06/2012 CRANE LIFT STUDY – CHECK LIST PROJECT NUMBER WORKS MANAGER DOCUMENT NUMBER Page 2 of 6 PROJECT TITLE SITE MANAGER DATE GENERAL REQUIREMENTS HAZARD CONTROL MEASURE Unacceptable lifting Equipment and arrangement Weight of Load to be lifted (see page 4) Weight of Lifting Equipment (see page 4) Total Weight (see page 4) Load Slinging Arrangement Agreed Slinging Points Assessed as Suitable The Need for Load Control Assessed Review daily crane operational check list Control and slinging / rigging by certified rigger / dogman Radius from Centre of Crane to Centre of Load From Crane Chart - Capacity of Crane as per Radius Location of crane confirmed Crane Operating Correctly (Limits, Faults, Remotes, Speed, Brakes etc) Area Clear for Lift and no Obstructions in Lift Path Landing Floor Clear & Prepared Floor Loading Confirmed Acceptable Ground condition checked and suitable Incorrect operation of Crane Unsuitable Crane Position Unsuitable Crane Condition Unsuitable Landing Area Soft or Unsuitable Ground N/A CHECKED Location of underground services checked and marked Overhead Hazards Faulty Communications Fences or Buildings in Close Proximity High Winds, Snow, Electrical Storms Etc Unsuitable Lifting Gear Selection Unauthorised Access Stable operating surface and levelling blocks Area checked for powerlines and other obstructions and adequate clearance available Communication system checked and operational Working Radius established and marked Weather conditions checked and favourable Lifting Gear adequate, inspected & tagged, certified with SWL, suitable for task, checked and in good condition. E.g. Shackles, Strops, Slings, Chains, Lifting / Spreader Beams etc Restrict Access to work area. Signs / barricades Warning siren DOCUMENT REFERENCE: CL – 07 – 02 REVISION: 4 HYDRO-285-68 DATE: 19/06/2012 CRANE LIFT STUDY – CHECK LIST PROJECT NUMBER WORKS MANAGER DOCUMENT NUMBER Page 3 of 6 PROJECT TITLE SITE MANAGER DATE GENERAL REQUIREMENTS HAZARD Falls From Heights Lack of Coordination SLING PLANT ID NUMBER CONTROL MEASURE N/A CHECKED Provision of fixed access scaffold Elevated work platform or similar Safety Harness and Lanyard Works Manager to supervise or delegate responsibility Works Manager to notify Production manager of date and time of lifts Works Manager to notify Generation Operations of date and time of lifts Contractor to have direct communication with Works Manager S.W.L DOCUMENT REFERENCE: CL – 07 – 02 WITHIN CURRENT CERTIFICATION REVISION: 4 VISUALLY INSPECTED HYDRO-285-68 N/A CHECKED DATE: 19/06/2012 CRANE LIFT STUDY – CHECK LIST PROJECT NUMBER WORKS MANAGER DOCUMENT NUMBER Page 4 of 6 PROJECT TITLE SITE MANAGER DATE DESCRIPTION NO YES Does the task require the use of multiple cranes Location on Site of Lift Date of Lift Person Supervising the Lift Position CRANE AND PERSONNEL DETAILS CRANE 1 Crane Type Crane Owner Capacity(SWL) Crane Driver Rigger(s) Ticket No(s) Ticket No(s) CRANE 2 Crane Type Crane Owner Capacity(SWL) Crane Driver Rigger(s) Ticket No(s) Ticket No(s) CRANE 3 Crane Type Crane Owner Capacity(SWL) Crane Driver Rigger(s) CRANE NUMBER CRANE 1 CRANE 2 CRANE 3 ESTIMATED SHARE OF LOAD (%) Ticket No(s) Ticket No(s) RADIUS FROM CRANE TO LOAD (M) CAPACITY OF CRANE FROM CHARTS (T) ADJUSTED CAPACITY (SEE NOTE) (T) ESTIMATE LOAD FOR EACH CRANE (T) TOTAL CAPACITY NOTE: For Multiple crane lifts, it is a statutory requirement that the capacity of each crane at the require boom or jib length be as follows. For Two Cranes: 20 percent in excess of calculated load share For Three Cranes: 33 percent in excess of calculated load share DOCUMENT REFERENCE: CL – 07 – 02 REVISION: 4 HYDRO-285-68 DATE: 19/06/2012 CRANE LIFT STUDY – CHECK LIST PROJECT NUMBER WORKS MANAGER DOCUMENT NUMBER Page 5 of 6 PROJECT TITLE SITE MANAGER DATE SKETCH OF LIFT DOCUMENT REFERENCE: CL – 07 – 02 REVISION: 4 HYDRO-285-68 DATE: 19/06/2012 CRANE LIFT STUDY – CHECK LIST PROJECT NUMBER WORKS MANAGER DOCUMENT NUMBER Page 6 of 6 PROJECT TITLE SITE MANAGER DATE SITE REGISTRATION (Note: Applies to all Work Parties and personnel working on site) REQUIREMENT CHECKED Permit To Work issued Visitors register sheet or emergency board being used. Site Map issued (showing emergency assembly areas and fire equipment) Hydro Tasmania Level 2 O H & S Induction complete Hydro Tasmania Level 3 Site induction complete S ADDITIONAL PERSONAL PROTECTIVE EQUIPMENT (COMPLIANT WITH AUSTRALIAN STANDARDS) REQUIREMENT CHECKED REQUIREMENT CHECKED REQUIREMENT CHECKED CERTIFICATION I have personally checked and verified all items on all pages of this check list Works Manager Name Signature Date I acknowledge and agree that all items are detailed on all pages of this check list. I agree to ensure that all employees and sub-contractors engaged in this work will fully comply with all control measures indicated Manager of Work Party Name Signature Date DAILY REVIEW IF THERE IS A SIGNFICANT CHANGE IN WORK AND OR CONDITIONS A NEW CHECK LIST IS REQUIRED DATE AND TIME DOCUMENT REFERENCE: CL – 07 – 02 REVIEWED / COMMENT REVISION: 4 NEW CHECK LIST REQUIRED HYDRO-285-68 DATE: 19/06/2012