1 - Valero

advertisement

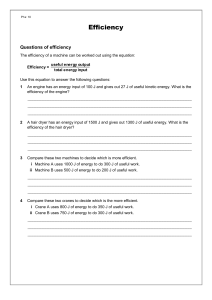

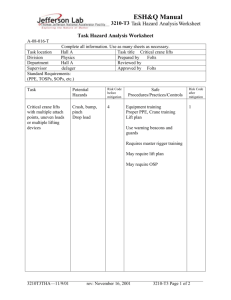

VALERO – KROTZ SPRINGS SHG #36 Page 1 of 8 Revised 11/18/02 CRITICAL LIFT GUIDELINE 1.0 PURPOSE The purpose is to establish minimum guidelines used when performing critical lifts in Valero Krotz Springs Refinery. 2.0 SCOPE This guideline is applicable to all critical lifts performed within the refinery. 3.0 DEFINITIONS Crane - A lifting device using a boom and cable to raise and lower materials and personnel, i.e., 18-ton cherry picker, 8-ton carry-deck, etc. Crane Operator - Any employee or contractor who operates a crane. Crane Owner - The Director or designee responsible for the maintenance, inspection and operation of any crane. Critical Lifts - Include: ∙ All lifts in which personnel are lifted. ∙ All lifts which exceed 80% of the crane’s total capacity. ∙ All lifts in which the load is 75,000 pounds or greater ∙ All lifts which exceed 70% of the load chart capacity in close proximity to operating or critical equipment. Close Proximity - for the purposes of critical lifts is determined by the consequences of a loss of control of the load (uncontrolled swinging or falling) or the actual load such that the impact of the load falling on the equipment would cause damage or an operational upset. Potential Critical Lifts - Lifts that could be deemed as critical by operations and maintenance supervision and/or safety personnel. These lifts include: ∙ Lifts near power lines or high voltage equipment. ∙ Lifts of special monetary value. ∙ Assembly of boom over operating units or other obstructions. ∙ Lifts which need modification or design of lifting equipment or special rigging configurations, including multi-crane lifts (except for the use of two or more cranes to extract and install exchanger tube bundles). ∙ Lifts deemed critical for other reasons even if less than 75,000 pounds. ∙ Lifts which are not completely routine. Lift Supervisor - An individual qualified to supervise or oversee critical lifts. VALERO – KROTZ SPRINGS 4.0 SHG #36 Page 2 of 8 Revised 11/18/02 RESPONSIBILITIES/REQUIREMENTS 4.1 GENERAL RESPONSIBILITES INDIVIDUAL/GROUP RESPONSIBILITIES/REQUIREMENTS Ensure that the crane is completely inspected per the manufacturer’s Crane Owner specifications listed in the service manual and meets all applicable federal, state and local regulations. Maintain a record of all-prior inspections, tests, repairs, maintenance, modifications and deficiencies. A contractor crane owner will make these records available for review upon request by the Company. Maintain records of the identification, capability, training and competence of all crane operators and site support personnel. Joint completion of a Critical Lift Permit with crane operator prior to Lift Supervisor making any critical lift (see Attachment 1) and a “Personnel Basket Authorization form (Attachment 3) prior to making a personnel lift. Joint approval of personnel lifting baskets with Safety prior to their use. Forward copies of the completed lifting plans to Maintenance Department equipment files and any completed critical lift permit to the Refinery Safety Department for retention. Inspect the hoisting equipment using the checklist provided as Crane Operator Attachment 2, prior to a critical lift; any deficiencies noted that will affect the safe operation of the crane must be corrected prior to making a critical lift. Inspect all rigging devices with rigger before use and adhere to all manufacturers' use recommendations and capacity limitations. Practice sound operating procedures according to all accredited trade and professional organizations regarding crane rigging and lifting work (i.e., API, SAE, ANSI, ASME, etc.). Maintain proof of their qualification including the size and/or type of equipment they are qualified to operate and the date/expiration date of their qualification. Copies of this certification must be available for review at all times. Assist in the joint completion and planning of all critical lifts, including the completion of a Pre-Critical Lift Checklist and Critical Lift Permit. Participate in the Pre-Lift Meeting held prior to all critical lifts. Assist in site preparation. Rigger Inspect all rigging devices with crane operator and adhere to all manufacturers' use recommendations and capacity limitations. Follow general safety rules and procedures. Will inspect and tag all Valero owned slings, chokers, lifting devices, etc Valero Tool Room quarterly. The tagging procedure will be the same as with the extension cord Attendant program: First Quarter Second Quarter Third Quarter Fourth Quarter - White Red Blue Green Store critical lift radios and maintain in good condition with batteries fully charged. Maintain a check out log to track the use of radios. VALERO – KROTZ SPRINGS Equipment/Crane Safety Department 5.0 SHG #36 Page 3 of 8 Revised 11/18/02 Must have an annual inspection of the hoisting machinery by a competent person, or by a government or private agency recognized by the U.S. Department of Labor. Must have a current inspection sticker displayed or current inspection documentation available at the job site. Must have rated load capacities, recommended operating speeds, special hazard warnings, or instructions conspicuously placed on all equipment visible to the operator while at the control station. Joint approval of personnel lift baskets with Maintenance or Contractor Supervisor. Maintain copies of completed lifting permits in accordance with site policies. CRITICAL LIFT APPROVALS 5.1 CRITICAL LIFT PERMITS Lifts that are handled as critical require the completion of a “Critical Lift Permit” (Attachment 1) and a “Pre-Critical Lift Checklist” (Attachment 2). In addition, all personnel lifts also require the completion of a “Personnel Basket Authorization Form” (Attachment 3). All critical lifts shall be planned, permitted and made by trained and competent personnel in accordance with applicable OSHA rules and regulations. Critical lifts made by Valero maintenance personnel shall be made in accordance with Maintenance Craft Procedure CP 3.8. 5.2 PRE LIFT MEETING A meeting attended by the crane operator, signal person (if necessary), personnel to be lifted, the Valero maintenance/engineering representative, and a Safety representative shall be held to review requirements of this guideline and to see that they have been followed. This meeting shall be held prior to and after the trial lift at each new work location. 6.0 PERSONNEL LIFTS 6.1 GENERAL POLICY The use of a crane or derrick to hoist Valero or contractor personnel on a personnel platform is prohibited, except when alternative means to reach the worksite would be more hazardous or it is not possible because of structural design or worksite conditions. Use of a personnel basket/platform must be approved by maintenance supervision and the refinery Safety group. VALERO – KROTZ SPRINGS 6.2 SHG #36 Page 4 of 8 Revised 11/18/02 LIFTING REQUIREMENTS 6.2.1 CRANE OR DERRICK The load line hoist drum shall have a system or device on the power train, other than the load hoist brake, which regulates the lowering rate of speed (controlled load lowering). Free fall is prohibited. The crane shall be uniformly level within one percent of level grade. Cranes with variable angle booms shall be equipped with a boom angle indicator, readily visible to the operator. Cranes with telescoping booms shall be equipped with a device to indicate to the operator, the boom’s extended length. An anti-two blocking device or a system which deactivates the hoisting action before damage occurs in the event of a two blocking situation shall be used. The crane must be equipped with a load line capable of lifting seven times the maximum intended load weight. 6.2.2 PERSONNEL PLATFORM OR BASKET The basket/platform and suspension system shall be designed by a qualified engineer or a person competent in structural design. The basket/platform shall be capable of supporting, without failure, its own weight and at least five times the maximum intended load. The basket/platform shall be conspicuously posted with a plate or other permanent marking which indicates the weight of the basket/platform and its rated load capacity or maximum intended load. The basket/platform shall be equipped with the following guard rail system. ∙ Top (outer) guard rail - 42” high. ∙ Top (inner) grab rail inside the entire perimeter of personnel basket - 42” high. ∙ Midrail (with solid construction or expanded metal enclosure to the toe board). ∙ Toe board.Access gates, if installed, shall swing inwards and have a reliable closing latch. The basket/platform shall contain no openings larger than ½ inch in the bottom or sides up to the midrail. The basket/platform and rigging, including the shackles and wire rope, shall only be used for personnel basket/platform lifts. VALERO – KROTZ SPRINGS SHG #36 Page 5 of 8 Revised 11/18/02 The basket/platform shall have a structural member designed and located within the caged area that can easily have a body harness attached to support a fall should the platform tip over. Any materials or tools being used by the craftsmen must be secured during the lift. 6.2.3 TRIAL LIFT, INSPECTION, AND PROOF TESTING Prior to lifting personnel, a trial lift will be performed at each crane set up or change in hoisting sequences. The trial lift shall be made with the platform loaded to 125% of its rated capacity. The trial lift shall include a five-minute non-moving lift with the basket/platform suspended one foot off the ground. The basket/platform shall be set down after five minutes and the rigging and structure inspected for defects for repairs. The basket/platform will be hoisted and positioned (with the trial weight still in the cage) at each desired lift location. During the trial lift the crane operator shall determine that all systems, controls, and safety devices are functioning properly, that no interferences exist and that the entire lift can be made using less than 50% of the crane’s rated capacity. Prelift plans which show boom angle, maximum intended load, and radius to lift shall be prepared for all lifts. The number of personnel to be hoisted shall be kept to a minimum and in no case shall the number exceed (3) three. Personnel using the basket/platform shall be considered as weighing 250 pounds each, for the purpose of calculating maximum intended load. 6.3 COMMUNICATIONS Six radios are available to be used for heavy/critical lifts. These radios have only two channels, channels 10 & 11. The two channels are walkie-talkie capable, good for onemile range. They are set on frequencies that no other radios in our plant have. The radios are orange in color so that they cannot be confused with the common radios throughout the refinery. Usually 3 radios are used during heavy/critical lifts. The radios may be checked out from the Tool Room as needed. VALERO – KROTZ SPRINGS SHG #36 Page 6 of 8 Revised 11/18/02 ATTACHMENT 1 - CRITICAL LIFT PERMIT VALERO REFINING COMPANY - LOUISIANA CRITICAL LIFT? ITEM: POTENTIAL CRITICAL LIFT? DATE OF LIFT: A. Weight 1. Equipment Condition New Used 2. Weight Empty _____________________ lbs. 3. 10% of Empty Weight for Unaccounted Material in Equipment (if needed) ________ lbs. 4. Weight of Headache Ball, Block, Jib and Wire Rope ______________________ lbs. 5. Weight of Lifting Bar ______________ lbs. 6. Weight of Slings/Shackles__________ lbs. TOTAL WEIGHT _________________ lbs. Source of Weight _______________________ (Nameplate, Drawings, Calculated, etc.) (If calculated, by whom: _________________) C. Erection Crane 1. Type of Crane ________________________ 2. Rated Capacity (tons) __________________ 3. Lifting Arrangement a. Maximum distance, center of load to center pin of crane (feet) ______________ b. Length of boom (feet) ________________ c. Angle of boom at pickup (degrees) ______ d. Angle of boom at set (degrees) ________ e. Gross chart capacity of crane: _______lbs. 4. Net load on crane _____________ lbs. E. Pre-lift Check List 1. Weather Suitable Yes No 2. 3. 4. 5. 6. 7. 8. 9. Yes Yes Yes Yes Yes Yes Yes Yes No No No No No No No No Matting Acceptable Outriggers fully extended Crane in good condition Swing Room Head Room Checked Max Counterweights Used Tag Line Used Condition of Operator (experienced, rested, alert) 10. Experienced Flagman 11. Experienced Rigger 12. Brake Load Tested (when possible) Yes No Yes No Yes No 13. Unnecessary rigging removed 14. Method to stop/secure load during emergency discussed? Yes No Yes No B. Sizing of Slings 1. Sling Selection a. Type of Arrangement Vertical Basket Choked b. Number of slings in hook-up c. Sling load lbs. d. Sling size/cap. (SWL) lbs. 2. Shackle Selection a. Stock Diameter (inches) b. Capacity (tons) D. Tailing Crane 1. Type of Crane 2. Rated Capacity (tons) 3. Lifting Arrangement a. Maximum distance, center of load to center pin of crane feet) b. Length of boom (feet) c. Angle of boom at pickup (degrees) d. Angle of boom at set (degrees) e. Gross chart capacity of crane: lbs. 4. Max load on tailing crane lbs. F. Craftsmen on Job: __________________________________ __________________________________ __________________________________ __________________________________ PRE-LIFT MEETING HELD Yes No ______________________________________________ (Job Supervisor) ______________________________________________ (Equipment Operator) ______________________________________________ (Competent Person) VALERO – KROTZ SPRINGS SHG #36 Page 7 of 8 Revised 11/18/02 ATTACHMENT 2 VALERO REFINING COMPANY - LOUISIANA PRE-CRITICAL LIFT CHECKLIST Crane Operator/Company: Valero Representative: Rig Operator: Signalman: Date: Critical Lift Plan Description: Make Of Equipment: Model Number/Serial Number: Lifting Capacity: Lift Weight: / CHECK POINT 1. Load Line (Lubricated, Wound Properly On Drum, Condition) 2. Whip Line (Lubricated, Wound Properly On Drum, Condition) 3. Hook And Safety Latches On Load Block 4. Hook and Safety Latches On Headache Ball 5. Cable At Wear Points 6. Pins In Becket 7. Wedges Installed 8. Clamps On Dead Ends 9. Boom Line - Conventional Booms (Lubricated, Wound Properly On Drum Condition) 10. Hydraulic Oil Lines 11. Outriggers, Outrigger Pads and Pin 12. Lights, Turn Signals 13. Horn 14. Oil 15. Water 16. Boom Pins 17. Cotter Pins 18. Steering 19. Tires 20. Controls (Check Operation) 21. Brakes (Swing) Operate Against Engine Power 22. Instruments 23. Legible Load Chart 24. Clean Windshield, Windows, Check Wipers 25. Site Preparation Completed 26. Lift Area Barricaded 27. Load Brake Adjustment 28. Unnecessary Rigging Removed from Hook Acceptable Not Acceptable Not Applicable VALERO – KROTZ SPRINGS SHG #36 Page 8 of 8 Revised 11/18/02 ATTACHMENT 3 VALERO REFINING COMPANY - LOUISIANA PERSONNEL BASKET AUTHORIZATION FORM Date: Time: 1. Job to be performed (description and type of work to be performed). Give details concerning job scope, location and safety concerns. 2. Justification for utilizing personnel basket: 3. Make and number of crane: 4. Radius of lift 5. Angle of crane boom 6. Capacity of crane (from load chart) 7. Item 6 divided by 2 lbs (This limit shall NOT be exceeded!) 8. Number of persons to be lifted x 250 lbs. = 9. Weight of personnel basket: 10. Weight of tools and equipment to be lifted 11. Total weight to be lifted (sum of items 8, 9, & 10) must be less than item 7: 12. Test weight (125% of basket's rated capacity) 13. Was full cycle pre-lift test performed satisfactorily? Yes No 14. Was the anti-two blocking device tested? Yes No 15. Safety line from basket to load line? Yes No 16. Pre-lift meeting conducted? Yes No CAUTION: feet degrees Jib used:? Yes lbs Valero Representative Requesting Lift: Equipment Operator: Maintenance Pipefitter/Welder Supervisor: Owning Area Supervisor: Safety Supervisor: lbs. lbs. lbs. lbs. REMOVE ALL TEST WEIGHTS BEFORE LIFTING! Signatures Required: No lbs.