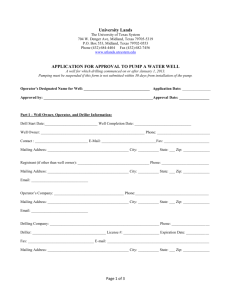

West Virginia Public Well Regulations

advertisement