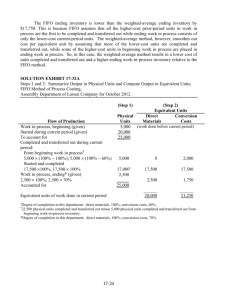

Process Costing: Chapter 16 Assignment Table

advertisement

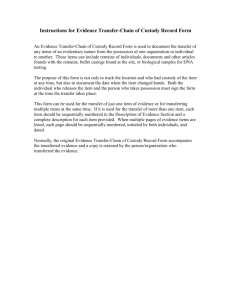

CHAPTER 16 Process Costing ASSIGNMENT CLASSIFICATION TABLE Exercises A Problems B Problems 1, 7, 16 1A 1B 1, 2, 3 1, 2, 11, 13, 14, 15, 16 1A 1B 10, 11, 12, 13 5, 10 3, 4, 5, 6, 7, 8, 10, 11, 12, 13, 14, 15, 16 2A, 3A, 4A, 5A, 6A 2B, 3B, 4B, 5B, 6B Explain the four steps necessary to prepare a production cost report. 8, 9, 14, 15, 18 4, 6, 7, 8, 9 3, 4, 5, 6, 7, 8, 10, 11, 12, 13, 14, 15, 16 2A, 3A, 4A, 5A 2B, 3B, 4B, 5B *7. Prepare a production cost report. 16, 17 12 5, 9, 10 2A, 3A, 4A, 5A, 6A 2B, 3B, 4B, 5B, 6B *8. Compute equivalent units using the FIFO method. 21, 22 11, 12, 13 13, 14, 15, 16, 17 7A 7B Study Objectives Questions *1. Understand who uses process cost systems. 1, 2, 19, 20 *2. Explain the similarities and differences between job order and process cost systems. 2, 3, 4 *3. Explain the flow of costs in a process cost system. 5, 6 *4. Make the journal entries to assign manufacturing costs in a process cost system. 6, 7 *5. Compute equivalent units. *6. Brief Exercises *Note: All asterisked Questions, Exercises, and Problems relate to material contained in the appendix*to the chapter. 16-1 ASSIGNMENT CHARACTERISTICS TABLE Problem Number Description Difficulty Level Time Allotted (min.) 1A Journalize transactions. Moderate 2030 2A Complete four steps necessary to prepare a production cost report. Simple 3040 3A Complete four steps necessary to prepare a production cost report. Simple 3040 4A Assign costs and prepare a production cost report. Moderate 2030 5A Determine equivalent units and unit costs and assign costs. Moderate 2030 6A Compute equivalent units and complete a production cost report. Moderate 1525 Determine equivalent units and unit costs and assign costs for processes; prepare production cost report. Moderate 3040 1B Journalize transactions. Moderate 2030 2B Complete four steps necessary to prepare a production cost report. Simple 3040 3B Complete four steps necessary to prepare a production cost report. Simple 3040 4B Assign costs and prepare a production cost report. Moderate 2030 5B Determine equivalent units and unit costs and assign costs. Moderate 2030 6B Compute equivalent units and complete a production cost report. Moderate 1525 Determine equivalent units and unit costs and assign costs for processes; prepare production cost report. Moderate 3040 *7A* *7B* 16-2 BLOOM’S TAXONOMY TABLE 16-3 ANSWERS TO QUESTIONS 1. (a) (b) (c) (d) Process cost. Process cost—(Possibly job order if unique automobile). Job order. Job order. 2. The primary focus of job order cost accounting is on the individual job. In process cost accounting, the primary focus is on the processes involved in producing identical or very similar products. 3. The similarities are: (1) all three manufacturing cost elements—direct materials, direct labor, and manufacturing overhead—are the same; (2) the accumulation of the costs of materials, labor, and overhead is the same; and (3) the flow of costs is the same. 4. The features of process cost accounting are: (1) separate work in process accounts for each process, (2) production cost reports, (3) product costs computed for each accounting period, and (4) unit costs computed based on total manufacturing costs. 5. Tina is correct. The flow of costs is the same in process cost accounting as in job order cost accounting. The method of assigning costs, however, is significantly different. 6. (a) (1) Materials are charged to production on the basis of materials requisition slips. (2) Labor is usually charged to production on the basis of the payroll register or departmental payroll summaries. (b) The criterion used in assigning overhead to processes is to identify the activity that “drives” or causes the cost. In many companies this activity is machine time, not direct labor. 7. The entry to assign overhead to production is: July 31 Work in Process—Machining .................................................... Work in Process—Assembly ..................................................... Manufacturing Overhead ................................................... 45,000 36,000 81,000 8. To prepare a production cost report, four steps are followed: (a) compute the physical unit flow, (b) compute equivalent units of production, (c) compute unit production costs, and (d) prepare a cost reconciliation schedule. 9. Physical units to be accounted for consist of units in process at the beginning of the period plus units started (or transferred) into production during the period. Units accounted for consist of units completed and transferred out during the period plus units in process at the end of the period. 10. Equivalent units of production measure the work done during the period, expressed in fully completed units. 11. Equivalent units are the sum of: (1) units completed and transferred out and (2) equivalent units of ending work in process. 12. Units started into production were 9,600 (9,000 + 600). 16-4 Questions Chapter 16 (Continued) *13. Equivalent Units Materials Conversion Costs 12,000 12,000 Units transferred out Work in process 600 X 100% 600 X 20% Total equivalent units *14. 600 00,000 12,600 Units transferred out were 3,400 Units to be accounted for Work in process (beginning) Started into production Total units 120 12,120 800 3,000 3,800 Units accounted for Completed and transferred out Work in process (ending) Total units 3,400 400 3,800 *15. (a) The cost of the units transferred out is $168,000 (14,000 X $12). (b) The cost of the units in ending inventory is $10,500 [(2,000 X $3) + (500 X $9)]. *16. (a) Jim is incorrect. The report is an internal report for management. (b) There are four sections in a production cost report: (1) physical unit schedule, (2) equivalent unit determination, (3) unit costs, and (4) cost reconciliation schedule. *17. The production cost report provides the basis for evaluating: (1) the productivity of a department, (2) whether unit and total costs are reasonable, and (3) whether management’s predetermined quantity and cost goals are being met. *18. The per unit conversion cost is $10.625. [Conversion costs = Total costs = $6,600 – $3,200 = $3,400. Equivalent units for conversion costs are 320 (800 X 40%); The per unit conversion cost is $3,400 ÷ 320 = $10.625.] *19. Operations costing is similar to process costing in that standardized methods are used to manufacture the product. At the same time, the product may have some customized individual features that require the use of a job order cost system. *20. In deciding which system to use, a cost-benefit tradeoff occurs. In a job order system, detailed information related to the cost of the product is provided. The cost of implementing this system is often expensive. In a process cost system, an average cost of the product will suffice and therefore the cost to implement is less. In summary, the cost of implementing the system must be balanced against the benefits provided from the additional information. *21. Units transferred out were 2,600 (2,000 + 600). *22. (a) The cost of the units transferred out is $144,000 (12,000 X $12). (b) The cost of the units in ending inventory is $10,500 [(2,000 X $3) + (500 X $9)]. 16-5 SOLUTIONS TO BRIEF EXERCISES BRIEF EXERCISE 16-1 May 31 31 Raw Materials Inventory ................................. Accounts Payable .................................... 60,000 Factory Labor .................................................. Wages Payable ........................................ 40,000 60,000 40,000 BRIEF EXERCISE 16-2 May 31 31 Work in Process—Assembly Department ..... Work in Process—Finishing Department ...... Raw Materials Inventory .......................... 29,000 31,000 Work in Process—Assembly Department ..... Work in Process—Finishing Department ...... Factory Labor ........................................... 28,000 12,000 60,000 40,000 BRIEF EXERCISE 16-3 May 31 Work in Process—Assembly Department ..... ($28,000 X 150%) Work in Process—Finishing Department ...... ($12,000 X 150%) Manufacturing Overhead......................... 42,000 18,000 60,000 BRIEF EXERCISE 16-4 Beginning work in process Started into production Total units to be accounted for Transferred out Ending work in process Total units accounted for 16-6 January 0 25,000 25,000 March 0 34,000 34,000 July 0 60,000 60,000 20,000 5,000 25,000 30,000 4,000 34,000 50,000 10,000 60,000 BRIEF EXERCISE 16-5 January March July Materials 25,000 (20,000 + 5,000) 34,000 (30,000 + 4,000) 60,000 (50,000 + 10,000) Conversion Costs 22,000 (20,000 + 2,000) 33,000 (30,000 + 3,000) 52,500 (50,000 + 2,500) BRIEF EXERCISE 16-6 Total materials costs $52,000 Total conversion costs $60,000 Unit materials cost $5.20 ÷ Equivalent units of materials 10,000 ÷ Equivalent units of conversion costs 12,000 + Unit conversion cost $5.00 = Unit materials cost $5.20 = Unit conversion cost $5.00 = Total manufacturing cost per unit $10.20 BRIEF EXERCISE 16-7 Assignment of Costs Transferred out Transferred out Work in process, 3/31 Materials Conversion costs Total costs Equivalent Units Unit Cost 40,000 $23 5,000 2,000 $ 8 $15 $920,000 $40,000 30,000 70,000 $990,000 BRIEF EXERCISE 16-8 Total materials costs $9,000 ÷ Equivalent units of materials 20,000 16-7 = Unit materials cost $.45 BRIEF EXERCISE 16-8 (Continued) Total conversion *costs* $41,800 ÷ Equivalent units of conversion costs 19,000 = Unit conversion cost $2.20 *$23,800 + $18,000 BRIEF EXERCISE 16-9 Costs accounted for Transferred out Work in process Materials Conversion costs Total costs (18,000 X $2.65) (2,000 X $.45) (1,000 X $2.20) $47,700 $ 900 2,200 3,100 $50,800 BRIEF EXERCISE 16-10 Units transferred out Work in process, November 30 Materials (3,000 X 100%) Conversion costs (3,000 X 40%) Total equivalent units Materials 8,000 Conversion Costs 8,000 3,000 00,000 11,000 1,200 9,200 *BRIEF EXERCISE 16-11 Costs to Be Assigned Assignment of Costs Equivalent Units Unit Cost Total Costs Assigned Transferred out Work in process, 3/1 Started and completed 0 30,000 $ 0 $20.00 $ 0 600,000 Work in process, 3/31 Materials Conversion costs 5,000 2,000 $ 8.00 $12.00 $40,000 24,000 $600,000 $664,000 16-8 64,000 $664,000 *BRIEF EXERCISE 16-12 Equivalent Units Conversion Materials Costs Units accounted for completed and transferred out Work in process, March 1 Started and completed Work in process, March 31 Total units -030,000 5,000 35,000 -030,000 2,000 32,000 MORA COMPANY (Partial) Production Cost Report For the Month Ended March 31 COSTS Materials Unit costs Costs in March (a) Equivalent units (b) Unit costs (a) ÷ (b) Costs to be accounted for In process, March 1 Costs in March Total costs Costs accounted for Transferred out In process, March 1 Started and completed (30,000 units X $20.00) In process, March 31 Materials (5,000 X $8.00) Conversion costs (2,000 X $12.00) Total costs $280,000* 35,000 $8.00 Conversion Costs Total $384,000** $664,000 32,000 $12.00 $20.00 $ 0 664,000 $664,000 $ 0 600,000 $ 40,000 24,000 *35,000 equivalent units X $8.00 per unit **32,000 equivalent units X $12.00 per unit 16-9 64,000 $664,000 *BRIEF EXERCISE 16-13 Total materials costs 1 $70,0001 1 ÷ = Unit materials cost $3.50 = Unit conversion cost $2.00 $8,000 + $62,000 = $70,000 Total conversion costs 2 $38,0002 2 Equivalent units of materials 20,000 ÷ Equivalent units of conversion costs 19,000 $20,000 + $18,000 16-10 SOLUTIONS TO EXERCISES EXERCISE 16-1 March 31 Work in Process—Cooking ............................ Work in Process—Canning ............................ Raw Materials Inventory.......................... 14,000 6,000 31 Work in Process—Cooking ............................ Work in Process—Canning ............................ Factory Labor .......................................... 8,500 7,000 31 Work in Process—Cooking ............................ Work in Process—Canning ............................ Manufacturing Overhead ........................ 29,500 22,000 31 Work in Process—Canning ............................ Work in Process—Cooking ..................... 45,000 20,000 15,500 51,500 45,000 EXERCISE 16-2 1. 2. 3. 4. 5. Raw Materials Inventory ............................................ Accounts Payable .............................................. 56,300 Factory Labor ............................................................. Wages Payable ................................................... 55,000 Manufacturing Overhead........................................... Cash .................................................................... Accounts Payable .............................................. 70,000 Work in Process—Cutting......................................... Work in Process—Assembly .................................... Raw Materials Inventory .................................... 15,700 8,900 Work in Process—Cutting......................................... Work in Process—Assembly .................................... Factory Labor ..................................................... 28,000 27,000 16-11 56,300 55,000 36,000 34,000 24,600 55,000 EXERCISE 16-2 (Continued) 6. 7. 8. 9. Work in Process—Cutting ($1,640 X $20) ............ Work in Process—Assembly ($1,720 X $20) ........ Manufacturing Overhead ............................... 32,800 34,400 Work in Process—Assembly ................................ Work in Process—Cutting ............................. 77,600 67,200 77,600 Finished Goods Inventory ..................................... 135,000 Work in Process—Assembly ......................... 135,000 Cost of Goods Sold ............................................... 130,000 Finished Goods Inventory ............................. 130,000 Accounts Receivable ............................................. 200,000 Sales................................................................ 200,000 EXERCISE 16-3 (a) January May Total units to be accounted for Beginning work in process Started into production Total units 0 9,000 9,000 0 21,000 21,000 Total units accounted for Transferred out Ending work in process Total units 7,000 2,000 9,000 16,000 5,000 21,000 (b) (1) January March May July Materials 9,000 ( 7,000 + 2,000) 15,000 (12,000 + 3,000) 21,000 (16,000 + 5,000) 11,500 (10,000 + 1,500) 16-12 (2) Conversion Costs 8,400 [ 7,000 + (2,000 X 70%)] 12,900 [12,000 + (3,000 X 30%)] 20,000 [16,000 + (5,000 X 80%)] 10,600 [10,000 + (1,500 X 40%)] EXERCISE 16-4 Equivalent Units Conversion (1) Materials (2) Costs 9,000 9,000 (a) Units transferred out Work in process, July 31 1,000 X 100% 1,000 X 40% Total equivalent units 1,000 0, 000 10,000 400 9,400 (b) Materials: $45,000 ÷ 10,000 = $4.50 Conversion costs: ($14,940 + $18,900) ÷ 9,400 = $3.60 Costs accounted for Transferred out (9,000 X $8.10) Work in process, July 31 Materials (1,000 X $4.50) Conversion costs (400 X $3.60) Total costs $72,900 $4,500 1,440 16-13 5,940 $78,840 EXERCISE 16-5 HAN FURNITURE COMPANY Sanding Department Production Cost Report For the Month Ended April 30, 2007 Physical Units Quantities Units to be accounted for Work in process, April 1 Started into production Total units 0 15,000 15,000 Units accounted for Transferred out Work in process, April 30 Total units 12,000 3,000 15,000 Costs Unit costs Costs in April Equivalent units Unit costs (a) ÷ (b) (a) (b) Equivalent Units Conversion Materials Costs 12,000 3,000 15,000 12,000 1,200 13,200 (3,000 X 40%) Materials Conversion Costs $36,000 15,000 $2.40 $67,320 13,200 $5.10 Costs to be accounted for Work in process, April 1 Started into production Total costs Total $103,320 $7.50 $ 0 103,320 $103,320 Cost Reconciliation Schedule Costs accounted for Transferred out (12,000 X $7.50) Work in process Materials (3,000 X $2.40) Conversion costs (1,200 X $5.10) Total costs $ 90,000 $7,200 6,120 16-14 13,320 $103,320 EXERCISE 16-6 (a) Units transferred out Work in process, May 31 2,000 X 100% 2,000 X 25% Equivalent Units Conversion Materials Costs 8,000 8,000 2,000 0, 000 10,000 500 8,500 Materials $100,000 Conversion Costs $75,000 $800,000 $900,000 10,000 $90 $350,000 $425,000 8,500 $50 (b) Work in process, May 1 Costs added to production during May Total costs Equivalent units Unit costs (c) Transferred out (8,000 X $140) Work in process Materials (2,000 X $90) Conversion costs (500 X $50) Total costs Total $1,325,000 $140 $1,120,000 $180,000 25,000 205,000 $1,325,000 EXERCISE 16-7 (a) Work in process, July 1 Started into production Total units to be accounted for Less: Transferred out Work in process, July 31 700 1,100 1,800 1,300 500 (b) Equivalent Units Materials Conversion Costs 1,300 1,300 Units transferred out Work in process, July 31 500 X 100% 500 X 40% 500 0,000 1,800 16-15 200 1,500 EXERCISE 16-7 (Continued) Work in process, July 1 Costs added Total materials cost Direct Materials $2,900 6,100 $9,000 Conversion Costs $1,550 4,150 ($2,500 + $1,650) $5,700 $9,000 ÷ 1,800 = $5.00 (c) $5,700 ÷ 1,500 = $3.80 (d) Transferred out (1,300 X $8.80) $11,440 (e) Work in process Materials (500 X $5.00) Conversion costs (200 X $3.80) $2,500 760 $3,260 EXERCISE 16-8 (a) Physical Units 1,600 11,000 12,600 Work in process, October 1 Units started into production Units transferred out (12,600 – 2000) Work in process, October 31 10,600 2,000 12,600 Equivalent Units Materials Conversion Costs 10,600 10,600 Units transferred out Work in process 2,000 X 100% 2,000 X 10% 2,000 00,000 12,600 16-16 200 10,800 EXERCISE 16-8 (Continued) (b) Materials Work in process, October 1 Direct materials $ 20,000 Costs added to production during October 162,700 Total materials cost $182,700 $182,700 ÷ 12,600 = $14.50 (Materials cost per unit) Conversion Costs Work in process, October 1 Conversion costs $ 43,180 Costs added to production during October Conversion costs ($100,080 + $250,940) Total conversion costs 351,020 $394,200 $394,200 ÷ 10,800 = $36.50 (c) Costs accounted for Transferred out (10,600 X $51.00) Work in process, October 31 Materials (2,000 X $14.50) Conversion costs (200 X $36.50) $540,600 $29,000 7,300 Total costs 36,300 $576,900 16-17 EXERCISE 16-9 To: Mary Mahr From: Student Re: Ending inventory The reason for any confusion related to your department’s ending inventory quantity stems from the fact that the quantity can be measured in two different ways, depending on what the information is used for. The ending inventory quantity can be measured in physical units or equivalent units. Physical units are actual units present without regard to the stage of completion. Your department’s ending inventory in physical units is at least double the amount reported as equivalent units. Equivalent units measure the work done on the physical units, expressed in terms of fully completed units. Therefore, if your ending inventory contains 2,000 units which are 50% complete, that is equivalent to having 1,000 completed units at month end. Therefore, that ending inventory could be expressed as containing 2,000 physical units or 1,000 equivalent units. I hope this clears up any misunderstandings. Please contact me if you have any further questions. 16-18 EXERCISE 16-10 MARLIN MANUFACTURING COMPANY Welding Department Production Cost Report For the Month Ended February 28, 2007 Quantities Physical Units Equivalent Units Conversion Materials Costs (Step 1) (Step 2) Units to be accounted for Work in process, February 1 Started into production Total units 15,000 60,000 75,000 Units accounted for Transferred out Work in process, February 28 Total units 49,000 26,000 75,000 Costs Unit costs (Step 3) Costs in February Equivalent units Unit costs (a) ÷ (b) 49,000 26,000 75,000 49,000 5,200 54,200 Materials Conversion Costs (a) $195,000 (b) 75,000 $2.60 $130,080* 54,200 $2.40 Costs to be accounted for Work in process, February 1 Started into production ($180,000 + $35,100 + $64,545) Total costs Total $325,080 $5.00 $ 45,435 279,645 $325,080 Cost Reconciliation Schedule (Step 4) Costs accounted for Transferred out (49,000 X $5.00) Work in process, February 28 Materials (26,000 X $2.60) Conversion costs (5,200 X $2.40) Total costs $245,000 $67,600 12,480 *($30,435 + $35,100 + $64,545) 16-19 80,080 $325,080 EXERCISE 16-11 (a) Containers in transit, April 1 Containers loaded Total containers 0 800 800 Containers off-loaded Containers in transit, April 30 Total containers (b) Containers off-loaded Containers in transit, April 30 Total equivalent units *350 x 40% = 140 **350 x 30% = 105 450 350 800 Equivalent Units Physical Direct Conversion Units Materials Costs 450 450 450 350 140* 105** 590 555 EXERCISE 16-12 (a) Materials 800 200* 1,000 Applications transferred out Work in process, September 30 Equivalent units Conversion Costs 800 120** 920 *100 + 900 – 800 = 200 **200 X 60% = 120 (b) Materials: $5,000 ÷ 1,000 = $5.00 Conversion costs: $25,400* ÷ 920 = $27.609 Costs accounted for: Transferred out (800 X $32.609) Work in process, September 30 Materials (200 X $5.00) Conversion costs (120 X $27.609) Total costs *($4,000 + $12,000 + $9,400) 16-20 $26,087 $1,000 3,313 4,313 $30,400 EXERCISE 16-13 (a) Applications completed: Work in process, September 1 Started and completed Work in process, September 30 Total units Physical Units Equivalent Units Conversion Materials Costs 100 700 200 1,000 0 700 200 900 60 700 120 880 (b) Materials: $4,000 ÷ 900 = $4.444 Conversion costs: $21,400* ÷ 880 = $24.318 *($12,000 + $9,400) Costs accounted for: Applications completed: Work in process, September 1 Conversion costs (60 x $24.318) Started and completed (700 x $28.762) Work in process, September 30: Materials (200 x $4.444) Conversion costs (120 x $24.318) Total costs $5,000 1,459 $ 6,459 20,134* 889 2,918 $26,593 3,807 $30,400** *Adjusted for $1 rounding error **Total costs to be accounted for: $1,000 + $4,000 + $4,000 + $12,000 + $9,400 = $30,400 16-21 *EXERCISE 16-14 (a) (1) Materials: Production Data Physical Units Materials Added This Period Equivalent Units 0 8,000 1,000 9,000 %100 100% 100% 0 8,000 1,000 9,000 Work in process, August 1 Started and completed Work in process, August 31 Total (2) Conversion Costs: Physical Units Production Data Work in process, August 1 Started and completed Work in process, August 31 Total (b) Unit costs are: Materials Conversion costs Total Costs to Be Assigned 0 8,000 1,000 9,000 Equivalent Units % 0 100 40 0 8,000 400 8,400 $45,000 ÷ 9,000 = $5 $33,600 ÷ 8,400 = 4 $9 Assignment of Costs Total mfg. costs Transferred out Work in process, August 1 $78,600 (1) Started and completed Work in process, August 31 Materials Conversion costs (1) $45,000 + $14,700 + $18,900. 16-22 Equivalent Unit Units Cost Total Costs Assigned 0 8,000 $0 $9 $ 0 72,000 1,000 400 $5 $4 $5,000 1,600 $72,000 6,600 $78,600 *EXERCISE 16-15 (a) (1) Materials Work in process, September 1 Started and completed Work in process, September 30 Total (2) Conversion Costs Work in process, September 1 Started and completed Work in process, September 30 Total (b) Materials Conversion costs (c) Costs to Be Assigned Total mfg. costs *$218,200* Physical Units Materials Added This Period Q 0% 100% Equivalent Units 1,000 14,000 100% 1,000 12,000 Physical Units Work Added This Period Equivalent Units 2,000 11,000 80% 100% 1,600 11,000 1,000 14,000 40% 400 13,000 Unit Cost Total Costs Assigned 2,000 11,000 0 11,000 $ 60,000 ÷ 12,000 = $ 5 $143,000 ÷ 13,000 = 11 $16 Assignment of Costs Equivalent Units Transferred out Work in process, 9/1 0 Conversion costs 1,600 Started and completed 11,000 Total costs transferred out Work in process, 9/30 Materials 1,000 Conversion costs 400 Total costs $ 0 $11 $16 $15,200 17,600 $ 5 $11 $5,000 4,400 $ 32,800 176,000 208,800 9,400 $218,200 *Work in process, September 1, $15,200 + materials costs $60,000 + labor and overhead costs $143,000. 16-23 *EXERCISE 16-16 (a) Work in process, March 1 Started into production Total units to be accounted for Less: Transferred out Work in process, March 31 800 1,000 1,800 1,300 500 (b) Materials: Physical Materials Added Equivalent Production Data Units This Period Units Work in process, March 1 800 %100 0 Started and completed 500 100% 500 Work in process, March 31 500 100% 500 Total 1,800 1,000 Unit cost = $6,600 ÷ 1,000 = $6.60. (c) Conversion costs: Physical Production Data Units Work in process, March 1 800 Started and completed 500 Work in process, March 31 500 Total 1,800 Work Added This Period 70% 100% 40% Equivalent Units 560 500 200 1,260 Unit cost = $2,500 + $1,280 = $3,780 ÷ 1,260 = $3.00. (d) In process, March 1 ......................................................... Conversion costs (560 X $3.00) ...................................... Total cost .......................................................................... $3,680 1,680 $5,360 (e) 500 X ($6.60 + $3.00) = $4,800. (f) Materials (500 X $6.60) ..................................................... Conversion costs (200 X $3.00) ...................................... Total cost of work in process, March 31 ........................ 16-24 $3,300 600 $3,900 *EXERCISE 16-17 HIROHAMA MANUFACTURING COMPANY Welding Department Production Cost Report For the Month Ended February 28, 2007 Quantities Physical Units (Step 1) Units to be accounted for Work in process, February 1 Started into production Total units 15,000 60,000 75,000 Units accounted for Completed and transferred out Work in process, February 1 Started and completed Total Work in process, February 28 Total units 15,000 35,000* 50,000 25,000 75,000 Equivalent Units Conversion Materials Costs (Step 2) 0 35,000 35,000 25,000 60,000 13,500 (15,000 X 90%) 35,000 48,500 5,000 (25,000 X 20%) 53,500 *(60,000 – 25,000) Costs Unit costs (Step 3) Costs in February Equivalent units Unit costs (a) ÷ (b) Materials (a) $192,000 (1) (b) 60,000 $3.20 Costs to be accounted for Work in process, February 1 Started into production Total costs Conversion Costs Total $107,000 (2) $299,000 53,500 $2.00 $5.20 $ 32,175 299,000 $331,175 16-25 *EXERCISE 16-17 (Continued) Cost Reconciliation Schedule Costs accounted for (Step 4) Transferred out Work in process, February 1 Costs to complete beginning work in process Conversion costs (13,500 X $2.00) Total costs Units started and completed (35,000 X $5.20) Total costs transferred out Work in process, February 28 Materials (25,000 X $3.20) Conversion costs (5,000 X $2.00) Total costs $32,175 27,000 (1) Cost of materials added $57,000 plus costs transferred in $135,000. (2) Labor $35,100 plus overhead $71,900. 16-26 $ 59,175 182,000 $241,175 80,000 10,000 90,000 $331,175 SOLUTIONS TO PROBLEMS PROBLEM 16-1A 1. 2. 3. 4. 5. 6. 7. 8. 9. Raw Materials Inventory ............................................ Accounts Payable .............................................. 25,000 Work in Process—Blending ...................................... Work in Process—Packaging ................................... Raw Materials Inventory .................................... 16,800 7,200 Factory Labor ............................................................. Wages Payable ................................................... 18,770 Work in Process—Blending ...................................... Work in Process—Packaging ................................... Factory Labor ..................................................... 12,230 6,540 Manufacturing Overhead........................................... Accounts Payable .............................................. 41,300 Work in Process—Blending (900 X $35) .................. Work in Process—Packaging (300 X $35) ................ Manufacturing Overhead ................................... 31,500 10,500 Work in Process—Packaging ................................... Work in Process—Blending .............................. 54,940 Finished Goods Inventory......................................... Work in Process—Packaging ............................ 74,490 Accounts Receivable ................................................. Sales ................................................................... 85,000 Cost of Goods Sold ................................................... Finished Goods Inventory ................................. 62,000 16-27 25,000 24,000 18,770 18,770 41,300 42,000 54,940 74,490 85,000 62,000 PROBLEM 16-2A (a) Physical units Units to be accounted for Work in process, January 1 Started into production Total units Units accounted for Completed and transferred out Work in process, January 31 Total units 0 43,000 43,000 40,000 3,000 43,000 (b) Equivalent units Units transferred out Work in process, January 31 3,000 X 100% 3,000 X 40% Total equivalent units (c) Materials Conversion costs Total manufacturing Materials 40,000 Conversion Costs 40,000 3,000 00,000 43,000 1,200 41,200 Unit Costs $12.80 ($550,400 ÷ 43,000) $7.20 ($296,640* ÷ 41,200) $20.00 ($12.80 + $7.20) *$126,640 + $170,000 (d) Costs accounted for Transferred out (40,000 X $20.00) Work in process, January 31 Materials (3,000 X $12.80) Conversion costs (1,200 X $7.20) Total costs 16-28 $800,000 $38,400 8,640 47,040 $847,040 PROBLEM 16-2A (Continued) (e) ZION CORPORATION Molding Department Production Cost Report For the Month Ended January 31, 2007 Quantities Physical Units Equivalent Units Conversion Materials Costs (Step 1) (Step 2) Units to be accounted for Work in process, January 1 Started into production Total units 0 43,000 43,000 Units accounted for Transferred out Work in process, January 31 Total units 40,000 3,000 43.000 Costs Unit costs (Step 3) Costs in January Equivalent units Unit costs [(a) ÷ (b)] 40,000 3,000 43,000 40,000 1,200 41,200 Materials Conversion Costs (a) $550,400 (b) 43,000 $12.80 $296,640 41,200 $7.20 Costs to be accounted for Work in process, January 1 Started into production Total costs (3,000 X 40%) Total $847,040 $20 $ 0 847,040 $847,040 Cost Reconciliation Schedule (Step 4) Costs accounted for Transferred out (40,000 X $20) Work in process, January 31 Materials (3,000 X $12.80) Conversion costs (1,200 X $7.20) Total costs $800,000 $38,400 8,640 16-29 47,040 $847,040 PROBLEM 16-3A (a) (1) Physical units R12 Refrigerators F24 Freezers Units to be accounted for Work in process, June 1 Started into production Total units 0 20,000 20,000 0 20,000 20,000 Units accounted for Transferred out Work in process, June 30 Total units 18,000 2,000 20,000 17,000 3,000 20,000 (2) Equivalent units R12 Refrigerators Conversion Materials Costs 18,000 18,000 Units transferred out Work in process, June 30 (2,000 X 100%) (2,000 X 70%) Total equivalent units 2,000 00,000 20,000 1,400 19,400 F24 Freezers Conversion Materials Costs 17,000 17,000 Units transferred out Work in process, June 30 (3,000 X 100%) (3,000 X 50%) Total equivalent units 3,000 00,000 20,000 16-30 1,500 18,500 PROBLEM 16-3A (Continued) (3) Unit costs Materials ($840,000 ÷ 20,000) ($700,000 ÷ 20,000) Conversion costs ($620,800* ÷ 19,400) ($555,000** ÷ 18,500) Total Plant A R12 Refrigerators $42 Plant B F24 Freezers $35 32 000 $74 30 $65 *$200,800 + $420,000 **$236,000 + $319,000 (4) Plant A R12 Refrigerators Costs accounted for Transferred out (18,000 X $74) Work in process Materials (2,000 X $42) Conversion costs (1,400 X $32.00) Total costs $1,332,000 $84,000 44,800 128,800 $1,460,800 Plant B F24 Freezers Costs accounted for Transferred out (17,000 X $65) Work in process Materials (3,000 X $35) Conversion costs (1,500 X $30) Total costs 16-31 $1,105,000 $105,000 45,000 150,000 $1,255,000 PROBLEM 16-3A (Continued) (b) STEIN CORPORATION Stamping Department—Plant A Production Cost Report For the Month Ended June 30, 2007 Quantities Physical Units Equivalent Units Conversion Materials Costs (Step 1) (Step 2) Units to be accounted for Work in process, June 1 Started into production Total units 0 20,000 20,000 Units accounted for Transferred out Work in process, June 30 Total units 18,000 2,000 20,000 Costs Unit costs (Step 3) Costs in June Equivalent units Unit costs [(a) ÷ (b)] 18,000 2,000 20,000 18,000 1,400 19,400 Materials Conversion Costs (a) $840,000 (b) 20,000 $42 $620,800 19,400 $32 Costs to be accounted for Work in process, June 1 Started into production Total costs (2,000 X 70%) Total $1,460,800 $74 $ 0 1,460,800 $1,460,800 Cost Reconciliation Schedule (Step 4) Costs accounted for Transferred out (18,000 X $74) Work in process, June 30 Materials (2,000 X $42) Conversion costs (1,400 X $32) Total costs $1,332,000 $84,000 44,800 16-32 128,800 $1,460,800 PROBLEM 16-4A (a) Physical Units Units to be accounted for Work in process, October 1 Started into production Total units 35,000 415,000 450,000 Units accounted for Transferred out Work in process, October 31 Total units 405,000 45,000 450,000 Equivalent Units Conversion Materials Costs 405,000 45,000 450,000 405,000 9,000* 414,000 *(45,000 X 20%) Materials cost Beginning work in process Added during month Total Equivalent units Cost per unit $ 9,000 1,071,000 $1,080,000 450,000 $2.40 Conversion costs Beginning work in process Added during month Total Equivalent units Cost per unit $ 27,400 221,000 $248,400 ($90,000 + $131,000) 414,000 $.60 (b) Costs accounted for Transferred out (405,000 X $3.00) Work in process, October 31 Materials (45,000 X $2.40) Conversion costs (9,000 X $.60) Total costs 16-33 $1,215,000 $108,000 5,400 113,400 $1,328,400 PROBLEM 16-4A (Continued) (c) ELITE COMPANY Assembly Department Production Cost Report For the Month Ended October 31, 2007 Quantities Physical Units Equivalent Units Conversion Materials Costs (Step 1) (Step 2) Units to be accounted for Work in process, October 1 Started into production Total units 35,000 415,000 450,000 Units accounted for Transferred out Work in process, October 31 Total units 405,000 45,000 450,000 Costs Unit costs (Step 3) Costs in October Equivalent units Unit costs [(a) ÷ (b)] 405,000 45,000 450,000 405,000 9,000 (45,000 X 20%) 414,000 Materials Conversion Costs (a) $1,080,000 (b) 450,000 $2.40 $248,400 414,000 $.60 Costs to be accounted for Work in process, October 1 Started into production Total costs Total $1,328,400 $3 $ 36,400 1,292,000* $1,328,400 Cost Reconciliation Schedule (Step 4) Costs accounted for Transferred out (405,000 X $3.00) Work in process, October 31 Materials (45,000 X $2.40) Conversion costs (9,000 X $.60) Total costs $1,215,000 $108,000 5,400 *($1,071,000 + $90,000 + $131,000) 16-34 113,400 $1,328,400 PROBLEM 16-5A (a) (1) Physical Units (2) Units to be accounted for Work in process, July 1 Started into production Total units 400 1,100 1,500 Units accounted for Transferred out Work in process, July 31 Total units 1,000 500 1,500 Materials cost Beginning work in process Added during month Total Equivalent units Cost per unit $10,000 50,000 $60,000 1,500 $40 Equivalent Units Conversion Materials Costs 1,000 500 1,500 Conversion costs Beginning work in process Added during month Total Equivalent units Cost per unit 1,000 50 1,050 (500 X 10%) $ 9,300 53,700 ($23,700 + $30,000) $63,000 1,050 $60 (3) Costs accounted for Transferred out (1,000 X $100) Work in process, July 31 Materials (500 X $40) Conversion costs (50 X $60) Total costs 16-35 $100,000 $20,000 3,000 23,000 $123,000 PROBLEM 16-5A (Continued) (b) SPRAGUE COMPANY Bicycle Department Production Cost Report For the Month Ended July 31, 2007 Quantities Physical Units Equivalent Units Conversion Materials Costs (Step 1) (Step 2) Units to be accounted for Work in process, July 1 Started into production Total units 400 1,100 1,500 Units accounted for Transferred out Work in process, July 31 Total units 1,000 500 1,500 1,000 500 1,500 Costs Unit costs (Step 3) Costs in July Equivalent units Unit costs [(a) ÷ (b)] (a) (b) 1,000 50 1,050 Materials Conversion Costs $60,000 1,500 $40 $63,000 1,050 $60 Costs to be accounted for Work in process, July 1 Started into production Total costs (500 X 10%) Total $123,000 $100 $ 19,300 103,700* $123,000 Cost Reconciliation Schedule (Step 4) Costs accounted for Transferred out (1,000 X $100) Work in process, July 31 Materials (500 X $40) Conversion costs (50 X $60) Total costs $100,000 $20,000 3,000 *($50,000 + $23,700 + $30,000) 16-36 23,000 $123,000 PROBLEM 16-6A (a) Computation of equivalent units Physical Units Units accounted for Transferred out Work in process, May 31 (3/4 materials, (1/4 conversion costs) Total units Equivalent Units Conversion Materials Costs 95,000 95,000 95,000 12,000 107,000 9,000 104,000 3,000 98,000 (b) Computation of May unit costs Materials: $166,400 ÷ 104,000 units = $1.60 Conversion cost: $98,000 ÷ 98,000 units = 1.00 Total unit cost, May $2.60 (c) Cost Reconciliation Schedule Costs accounted for Transferred out (95,000 X $2.60) Work in process, May 31 Materials (9,000 X $1.60) Conversion costs (3,000 X $1.00) Total costs 16-37 $247,000 $14,400 3,000 17,400 $264,400 *PROBLEM 16-7A (a) Bicycles (1) Equivalent units—Materials Materials Added This Period Physical Units Work in process, March 1 Started and completed Work in process, March 31 Total 200 800 (1,000 – 200) 200 1,200 * 0%* 100% 100% Equivalent Units 0 800 200 1,000 *All materials are added at the beginning of the production process Equivalent units—Conversion Conversion Added This Period Physical Units Work in process, March 1 Started and completed Work in process, March 31 Total 200 800 (1,000 – 200) 200 1,200 Equivalent Units 20% (1 – .8) 100% 40% 40 800 80 920 (2) Unit costs Materials $50,000 1,000 $50 Costs in March (a) Equivalent units (b) Unit costs (a) ÷ (b) Conversion **$55,200** 920 $60 **Direct Labor $25,200 + Manufacturing Overhead $30,000 16-38 *PROBLEM 16-7A (Continued) (3) Assignment of costs to units transferred out and in process Costs to Be Assigned Total mfg. costs ***$124,480*** Assignment of Costs Transferred out Work in process, March 1 Conversion Started and completed Total costs transferred out Work in process, March 31 Materials Conversion costs Total costs Equivalent Unit Units Cost 40 800 $ 60 $110 Total Costs Assigned $19,280 2,400 88,000 $109,680 200 80 $50 $60 10,000 4,800 14,800 $124,480 ***Work in process, March 1, $19,280 + Materials $50,000 + Labor $25,200 + Overhead $30,000 Tricycles (1) Equivalent units—Materials Physical Units Work in process, March 1 Started and completed Work in process, March 31 Total 100 740 (800 – 60) 60 900 Materials Added This Period * 0%* 100% 100% Equivalent Units 0 740 60 800 *All materials are added at the beginning of the production process Equivalent units—Conversion Physical Units Work in process, March 1 Started and completed Work in process, March 31 Total 100 740 (800 – 60) 60 900 16-39 Conversion Added This Period 25% (1 – .75) 100% 25% Equivalent Units 25 740 15 780 *PROBLEM 16-7A (Continued) (2) Unit costs Materials $38,400 800 $48 Costs in March (a) Equivalent units (b) Unit costs (a) ÷ (b) Conversion **$35,100** 780 $45 **Direct Labor $15,100 + Manufacturing Overhead $20,000 (3) Assignment of costs to units transferred out and in process Costs to Be Assigned Assignment of Costs Total mfg. costs Transferred out Work in process, March 1 ***$79,625*** Conversion Started and completed Total costs transferred out Work in process, March 31 Materials Conversion costs Total costs Equivalent Unit Units Cost 25 740 Total Costs Assigned $ 6,125 $45 1,125 $93 68,820 $76,070 60 15 $48 $45 2,880 675 3,555 $79,625 ***Work in process, March 1, $6,125 + Materials $38,400 + Labor $15,100 + Overhead $20,000 16-40 *PROBLEM 16-7A (Continued) (b) NICHOLAS COMPANY Production Cost Report—Bicycles For the Month Ended March 31 Quantities Physical Units Equivalent Units Conversion Materials Costs (Step 1) (Step 2) Units to be accounted for Work in process, March 1 Started into production Total units 200 1,000 1,200 Units accounted for Completed and transferred out Work in process, March 1 Started and completed Work In process, March 31 Total units 200 800 200 1,200 Costs Unit costs (Step 3) Costs in March (a) Equivalent units (b) Unit costs [(a) ÷ (b)] 0 800 200 1,000 40 800 80 920 Materials Conversion Costs $50,000 1,000 $50 $55,200 920 $60 Costs to be accounted for Work in process, March 1 Started into production Total costs $ 19,280 105,200* $124,480 Cost Reconciliation Schedule (Step 4) Costs accounted for Transferred out Work in process, March 1 Conversion costs to complete beginning inventory (40 X $60) Started and completed (800 X $110) Work in process, March 31 Materials (200 X $50) Conversion costs (80 X $60) Total costs $19,280 2,400 88,000 $10,000 4,800 *($50,000 + $25,200 + $30,000) 16-41 $109,680 14,800 $124,480 PROBLEM 16-1B 1. 2. 3. 4. 5. 6. 7. 8. 9. Raw Materials Inventory .................................. Accounts Payable .................................... 500,000 Work in Process—Mixing ................................ Work in Process—Packaging ......................... Raw Materials Inventory .......................... 210,000 45,000 Factory Labor ................................................... Wages Payable ......................................... 238,900 Work in Process—Mixing ................................ Work in Process—Packaging ......................... Factory Labor ........................................... 182,000 56,900 Manufacturing Overhead ................................. Accounts Payable .................................... 800,000 Work in Process—Mixing (28,000 X $24)........ Work in Process—Packaging ......................... (7,000 X $24) Manufacturing Overhead ......................... 672,000 168,000 Work in Process—Packaging ......................... Work in Process—Mixing ........................ 999,000 500,000 255,000 238,900 238,900 800,000 840,000 999,000 Finished Goods Inventory ............................... 1,455,000 Work in Process—Packaging .................. 1,455,000 Accounts Receivable ....................................... 2,500,000 Sales.......................................................... 2,500,000 Cost of Goods Sold ......................................... 1,500,000 Finished Goods Inventory ....................... 1,500,000 16-42 PROBLEM 16-2B (a) Physical units Units to be accounted for Work in process, June 1 Started into production Total units 0 20,000 20,000 Units accounted for Completed and transferred out Work in process, June 30 Total units 15,000 5,000 20,000 (b) Equivalent units Units transferred out Work in process, June 30 5,000 X 100% 5,000 X 40% Total equivalent units (c) Materials Conversion costs Total unit cost Materials 15,000 Conversion Costs 15,000 5,000 00,000 20,000 2,000 17,000 Unit Costs $14.30 ($286,000 ÷ 20,000) $12.70 ($215,900* ÷ 17,000) $27.00 ($14.30 + $12.70) *$114,000 + $101,900 (d) Costs accounted for Transferred out (15,000 X $27.00) Work in process, June 30 Materials (5,000 X $14.30) Conversion costs (2,000 X $12.70) Total costs 16-43 $405,000 $71,500 25,400 96,900 $501,900 PROBLEM 16-2B (Continued) (e) AQUATIC COMPANY Molding Department Production Cost Report For the Month Ended June 30, 2007 Quantities Physical Units Equivalent Units Conversion Materials Costs (Step 1) (Step 2) Units to be accounted for Work in process, June 1 Started into production Total units 0 20,000 20,000 Units accounted for Transferred out Work in process, June 30 Total units 15,000 5,000 20,000 Costs 15,000 5,000 20,000 Materials Unit costs (Step 3) Costs in June Equivalent units Unit costs [(a) ÷ (b)] (a) $286,000 (b) 20,000 $14.30 15,000 2,000 17,000 (5,000 X 40%) Conversion Costs $215,900 17,000 $12.70 Costs to be accounted for Work in process, June 1 Started into production Total costs Total $501,900 $27 $ 0 501,900 $501,900 Cost Reconciliation Schedule (Step 4) Costs accounted for Transferred out (15,000 X $27) Work in process, June 30 Materials (5,000 X $14.30) Conversion costs (2,000 X $12.70) Total costs $405,000 $71,500 25,400 16-44 96,900 $501,900 PROBLEM 16-3B (a) (1) Physical units Plant 1 T12 Tables Plant 2 C10 Chairs Units to be accounted for Work in process, August 1 Started into production Total units 0 20,000 20,000 0 15,000 15,000 Units accounted for Transferred out Work in process, August 31 Total units 18,000 2,000 20,000 14,500 500 15,000 (2) Equivalent units Units transferred out Work in process, August 31 (2,000 X 100%) (2,000 X 50%) Total equivalent units Units transferred out Work in process, August 31 (500 X 100%) (500 X 80%) Total equivalent units 16-45 Plant 1 T12 Tables Conversion Materials Costs 18,000 18,000 2,000 00,000 20,000 1,000 19,000 Plant 2 C10 Chairs Conversion Materials Costs 14,500 14,500 500 00,000 15,000 400 14,900 PROBLEM 16-3B (Continued) (3) Unit costs Materials ($380,000 ÷ 20,000) ($225,000 ÷ 15,000) Conversion costs ($266,000* ÷ 19,000) ($178,800** ÷ 14,900) Total T12 Tables $19 C10 Chairs $15 14 000 $33 12 $27 *$190,000 + $76,000 **$118,100 + $60,700 (4) T12 Tables Costs accounted for Transferred out (18,000 X $33) Work in process Materials (2,000 X $19) Conversion costs (1,000 X $14) Total costs $594,000 $38,000 14,000 52,000 $646,000 C10 Chairs Costs accounted for Transferred out (14,500 X $27) Work in process Materials (500 X $15) Conversion costs (400 X $12) Total costs 16-46 $391,500 $7,500 4,800 12,300 $403,800 PROBLEM 16-3B (Continued) (b) FREEDO INDUSTRIES INC. Cutting Department—Plant 1 Production Cost Report For the Month Ended August 31, 2007 Quantities Physical Units Equivalent Units Conversion Materials Costs (Step 1) (Step 2) Units to be accounted for Work in process, August 1 Started into production Total units 0 20,000 20,000 Units accounted for Transferred out Work in process, August 31 Total units 18,000 2,000 20,000 Costs Unit costs (Step 3) Costs in August Equivalent units Unit costs [(a) ÷ (b)] 18,000 2,000 20,000 18,000 1,000 19,000 Materials Conversion Costs (a) $380,000 (b) 20,000 $19 $266,000 19,000 $14 Costs to be accounted for Work in process, August 1 Started into production Total costs (2,000 X 50%) Total $646,000 $33 $ 0 646,000 $646,000 Cost Reconciliation Schedule (Step 4) Costs accounted for Transferred out (18,000 X $33) Work in process, August 31 Materials (2,000 X $19) Conversion costs (1,000 X $14) Total costs $594,000 $38,000 14,000 16-47 52,000 $646,000 PROBLEM 16-4B (a) Physical Units Units to be accounted for Work in process, November 1 Started into production Total units 30,000 640,000 670,000 Units accounted for Transferred out Work in process, November 30 Total units 645,000 25,000 670,000 Materials cost Conversion costs Beginning work in Beginning work in process $ 70,000 process Added during month 1,270,000 Added during month Total $1,340,000 Total Equivalent units Cost per unit 670,000 $2.00 Equivalent units Cost per unit Equivalent Units Conversion Materials Costs 645,000 25,000 670,000 645,000 10,000 655,000 $ 48,000 738,000 ($358,000 + $380,000) $786,000 655,000 $1.20 (b) Costs accounted for Transferred out (645,000 X $3.20) Work in process, November 30 Materials (25,000 X $2.00) Conversion costs (10,000 X $1.20) Total costs 16-48 $2,064,000 $50,000 12,000 62,000 $2,126,000 PROBLEM 16-4B (Continued) (c) WANG COMPANY Assembly Department Production Cost Report For the Month Ended November 30, 2007 Quantities Physical Units Equivalent Units Conversion Materials Costs (Step 1) (Step 2) Units to be accounted for Work in process, November 1 Started into production Total units 30,000 640,000 670,000 Units accounted for Transferred out Work in process, November 30 Total units 645,000 25,000 670,000 645,000 25,000 670,000 Costs Unit costs (Step 3) Costs in November Equivalent units Unit costs [(a) ÷ (b)] Materials (a) $1,340,000 (b) 670,000 $2.00 645,000 10,000 (25,000 X 40%) 655,000 Conversion Costs $786,000 655,000 $1.20 Costs to be accounted for Work in process, November 1 Started into production Total costs Total $2,126,000 $3.20 $ 118,000 2,008,000* $2,126,000 Cost Reconciliation Schedule (Step 4) Costs accounted for Transferred out (645,000 X $3.20) Work in process, November 30 Materials (25,000 X $2.00) Conversion costs (10,000 X $1.20) Total costs $2,064,000 $50,000 12,000 *($1,270,000 + $358,000 + $380,000) 16-49 62,000 $2,126,000 PROBLEM 16-5B (a) (1) Physical Units (2) Units to be accounted for Work in process, July 1 Started into production Total units 500 1,600 2,100 Units accounted for Transferred out Work in process, July 31 Total units 1,500 600 2,100 Equivalent Units Conversion Materials Costs Materials cost Conversion costs Beginning work in Beginning work in process $ 540 process Added during month 2,400 Added during month Total $2,940 Total 1,500 600 2,100 $ 500 2,980 $3,480 Equivalent units 2,100 Equivalent units 1,740 Cost per unit $1.40 Cost per unit $2.00 1,500 240 1,740 ($1,600 + $1,380) (3) Costs accounted for Transferred out (1,500 X $3.40) Work in process, July 31 Materials (600 X $1.40) Conversion costs (240 X $2.00) Total costs 16-50 $5,100 $840 480 1,320 $6,420 PROBLEM 16-5B (Continued) (b) CLEMENTE COMPANY Basketball Department Production Cost Report For the Month Ended July 31, 2007 Quantities Physical Units Equivalent Units Conversion Materials Costs (Step 1) (Step 2) Units to be accounted for Work in process, July 1 Started into production Total units 500 1,600 2,100 Units accounted for Transferred out Work in process, July 31 Total units 1,500 600 2,100 Costs Unit costs (Step 3) Costs in July Equivalent units Unit costs [(a) ÷ (b)] (a) (b) 1,500 600 2,100 1,500 240 1,740 Materials Conversion Costs $2,940 2,100 $1.40 $3,480 1,740 $2.00 Costs to be accounted for Work in process, July 1 Started into production Total costs (600 X 40%) Total $6,420 $3.40 $1,040 5,380* $6,420 Cost Reconciliation Schedule (Step 4) Costs accounted for Transferred out (1,500 X $3.40) Work in process, July 31 Materials (600 X $1.40) Conversion costs (240 X $2.00) Total costs $5,100 $840 480 *($2,400 + $1,600 + $1,380) 16-51 1,320 $6,420 PROBLEM 16-6B (a) Computation of equivalent units Equivalent Units Physical Conversion Units Materials Costs Units accounted for Transferred out Work in process, November 30 (50% materials, (25% conversion costs) Total units 130,000 130,000 130,000 40,000 170,000 20,000 150,000 10,000 140,000 (b) Computation of November unit costs Materials: $240,000 ÷ 150,000 units = $1.60 Conversion cost: $98,000 ÷ 140,000 units = .70 Total unit cost, November $2.30 (c) Cost Reconciliation Schedule Costs accounted for Transferred out (130,000 X $2.30) Work in process, November 30 Materials (20,000 X $1.60) Conversion costs (10,000 X $0.70) Total costs 16-52 $299,000 $32,000 7,000 39,000 $338,000 *PROBLEM 16-7B (a) Basketballs (1) Equivalent units—Materials Materials Added This Period Physical Units Work in process, August 1 Started and completed Work in process, August 31 Total 500 1,000 (1,600 – 600) 600 2,100 * Equivalent Units 0%* 100% 100% 0 1,000 600 1,600 *All materials are added at the beginning of the production process Equivalent units—Conversion Conversion Added This Period Physical Units Work in process, August 1 Started and completed Work in process, August 31 Total 500 1,000 (1,600 – 600) 600 2,100 Equivalent Units 40% (1 – .6) 100% 50% 200 1,000 300 1,500 (2) Unit costs Materials $1,600 1,600 $1 Costs in August (a) Equivalent units (b) Unit costs [(a) ÷ (b)] Conversion **$2,175** 1,500 $1.45 **Direct Labor $1,175 + Manufacturing Overhead $1,000 16-53 *PROBLEM 16-7B (Continued) (3) Assignment of costs to units transferred out and in process Costs to Be Assigned Assignment of Costs Total mfg. costs Transferred out Work in process, August 1 ***$4,900*** Conversion Started and completed Total costs transferred out Work in process, August 31 Materials Conversion costs Total costs Equivalent Unit Units Cost 200 1,000 1.45 2.45 Total Costs Assigned $1,125 290 2,450 $3,865 600 300 1.00 1.45 600 435 1,035 $4,900 ***Work in process, August 1, $1,125 + Materials $1,600 + Labor $1,175 + Overhead $1,000 Soccer balls (1) Equivalent units—Materials Physical Units Work in process, August 1 Started and completed Work in process, August 31 Total 200 1,850 (2,000 – 150) 150 2,200 Materials Added This Period * 0%* 100% 100% Equivalent Units 0 1,850 150 2,000 *All materials are added at the beginning of the production process Equivalent units—Conversion Physical Units Work in process, August 1 Started and completed Work in process, August 31 Total 200 1,850 (2,000 – 150) 150 2,200 16-54 Conversion Added This Period Equivalent Units 20% (1 – .8) 40 100% 1,850 70% 105 1,995 *PROBLEM 16-7B (Continued) (2) Unit costs Materials $2,600 2,000 $1.30 Costs in August (a) Equivalent units (b) Unit costs (a) ÷ (b) Conversion **$1,995** 1,995 $1 **Direct Labor $1,000 + Manufacturing Overhead $995 (3) Assignment of costs to units transferred out and in process Costs to Be Assigned Assignment of Costs Total mfg. costs Transferred out Work in process, August 1 ***$5,045*** Conversion Started and completed Total costs transferred out Work in process, August 31 Materials Conversion costs Total costs Equivalent Unit Units Cost 40 1,850 $1.00 $2.30 Total Costs Assigned $ 450 40 4,255 $4,745 150 105 $1.30 $1.00 195 105 300 $5,045 ***Work in process, August 1, $450 + Materials $2,600 + Labor $1,000 + Overhead $995 16-55 *PROBLEM 16-7B (Continued) (b) JESSICA COMPANY Production Cost Report—Basketballs For the Month Ended August 31 Quantities Physical Units Equivalent Units Conversion Materials Costs (Step 1) (Step 2) Units to be accounted for Work in process, August 1 Started into production Total units 500 1,600 2,100 Units accounted for Completed and transferred out Work in process, August 1 Started and completed Work in process, August 31 Total units 500 1,000 600 2,100 Costs Unit costs (Step 3) Costs in August (a) Equivalent units (b) Unit costs [(a) ÷ (b)] 0 1,000 600 1,600 200 1,000 300 1,500 Materials Conversion Costs $1,600 1,600 $1 $2,175 1,500 $1.45 Costs to be accounted for Work in process, August 1 Started into production Total costs $1,125 3,775* $4,900 Cost Reconciliation Schedule Costs accounted for Transferred out Work in process, August 1 Conversion costs to complete beginning inventory (200 X $1.45) Started and completed (1,000 X $2.45) Work in process, August 31 Materials (600 X $1) Conversion costs (300 X $1.45) Total costs $1,125 290 2,450 $ 600 435 *($1,600 + $1,175 + $1,000) 16-56 $3,865 1,035 $4,900 . BYP 16-1 GROUP DECISION CASE (a) The unit cost suggests that Joe took the total costs and divided these costs by the units started into production. Total costs charged to the Mixing Department ($88,000 + $600,000 + $785,800) divided by the units started during July (100,000 gallons), results in a per unit cost of $14.738 (1,473,800 ÷ 100,000). (b) The principal errors made by Joe were: (1) he did not compute equivalent units of production; (2) he did not use the weighted-average costing method; and (3) he did not assign costs to ending work-in-process. 16-57 BYP 16-1 (Continued) (c) BRITISH BEACH COMPANY Mixing Department Production Cost Report For the Month Ended July 31, 2007 Quantities Physical Units Equivalent Units Conversion Materials Costs (Step 1) (Step 2) Units to be accounted for Work in process, July 1 Started into production Total units 8,000 100,000 108,000 Units accounted for Transferred out Work in process, July 31 Total units 103,000 5,000 108,000 Costs Unit costs (Step 3) Costs in July Equivalent units Unit costs [(a) ÷ (b)] 103,000 5,000 108,000 103,000 1,000 104,000 Materials Conversion Costs (a) $621,000 (b) 108,000 $5.75 $852,800 104,000 $8.20 Costs to be accounted for Work in process, July 1 Started into production Total costs Total $1,473,800 $13.95 $ 88,000 1,385,800* $1,473,800 Cost Reconciliation Schedule (Step 4) Costs accounted for Transferred out (103,000 X $13.95) Work in process, July 31 Materials (5,000 X $5.75) Conversion costs (1,000 X $8.20) Total costs $1,436,850 $28,750 8,200 *($600,000 + $785,800) 16-58 36,950 $1,473,800 BYP 16-2 MANAGERIAL ANALYSIS (a) The unit cost of materials is $140 ($420,000 ÷ 3,000). (b) The materials cost of the goods transferred out is $350,000 (2,500 X $140). Conversion costs, therefore, are $200,000 ($550,000 – $350,000), and per unit conversion cost is $80 ($200,000 ÷ 2,500). (c) There are 500 units in ending work-in-process inventory (3,000 started – 2,500 transferred out). The materials cost is $70,000 (500 X $140). Thus, the conversion costs in the May 31 or ending inventory are $10,000. $10,000 divided by $80 per unit conversion cost equals 125 units or 25% (125 ÷ 500) complete. 16-59 BYP 16-3 REAL-WORLD FOCUS (a) Three types of manufacturing costs are accumulated in work in process: materials, labor, and manufacturing overhead. (b) To compute equivalent units, General Microwave must know when materials and conversion costs are used in production. If they are used at the same time, only one computation of equivalent units is required. However, if they are used at different times in the production process, separate computations must be made for materials and conversion costs. When separate computations are required, it is necessary to know for materials and for conversion costs: 1. The units transferred out during the period. 2. The percentage of work done on the ending work in process during the period. (c) In costing completed units that are transferred out, General Microwave must make the following assignments of manufacturing costs: 1. Units transferred out—total cost is computed by applying the manufacturing cost per unit for the current period to the units transferred out. 2. In addition, the ending work in process is assigned both materials and conversion costs based on per unit costs and percentage of completion. 16-60 BYP 16-4 EXPLORING THE WEB Answers will vary depending on companies chosen by students. 16-61 BYP 16-5 COMMUNICATION ACTIVITY To: Jenna Haines, Regional Sales Manager From: Student, Accounting Manager Re: Production Cost Reports Jenna, congratulations again on your promotion! It’s going to be great working with you. It reminds me of our days at Dairy-Freeze after school (although this work is more fun, and it certainly pays better!). I’ll try to clear up some of the questions you raised in your fax. Here in the Snack Foods Division we use process costing rather than the job order system that Special Projects uses. The reason for this is that we produce all our products in a more or less continuous process, even when we run occasional special orders. You see, all our workers are assigned a particular part of the process to control. One might be in charge of making sure the mixing machines work properly, while another verifies the weight of the finished products. Whichever job a worker is assigned, he or she stays with it to completion, or at least the completion of that particular process. That’s different from what you had in Special Projects, where workers moved from job to job. That’s why we don’t usually track the orders separately. Our special orders are for various quantities of the foods we produce, so only the Packing Department needs to be concerned with the particular set of products shipped to the particular customer—which is its ordinary concern anyway. Your next question was about what an equivalent unit is. Well, you know already that Special Projects bids on various jobs, and then costs are recorded when the jobs are complete. The costs accumulated on jobs that aren’t complete are reflected in Work in Process Inventory. We in Snack Foods can’t use that method for a simple reason—we produce our products in huge batches that we keep going fairly continuously. Or, in other words, we don’t have a “job” that we can record as “complete.” A batch may contain enough of our product to fill thirty or more orders, so we may have thirty or more “jobs” in each batch. One job may happen to be filled from two batches. Since the cost of each batch is about the same, it isn’t worth keeping track of separately. 16-62 BYP 16-5 (Continued) At the end of the month, we need to record what we finished and what still remains undone. Equivalent units are the way we measure the amount of work we have done on our work in process. It’s kind of like comparing the contents of 4-ounce cups with the contents of 12-ounce cups. It doesn’t make sense to compare by counting the number of cups you have. You need to find out how many ounces you have in one set; then you can get a meaningful comparison with the ounces you have in the other set. We compare by the number of “units” of materials or labor that are required to finish a product completely. If it requires 12 ounces of flour and 15 minutes of labor for a finished bag of pretzels, for example, then the 12 ounces and 15 minutes are “finished equivalents.” If we have enough pretzels to fill 30 bags, but we’ve only spent 5 minutes (or 1/3 of the total required) of labor on them at the end of the month, we could have used the same amount of time and completely finished 10 bags. Thus, we have the “equivalent” of 10 bags worth of labor. Your last question is the easiest to answer. You get four reports because we use four processes here in Snack Foods Division. Each process has to report its status at the end of every month. It’s kind of like we have four miniature factories, each reporting “completion” of a certain number of products. The products from one department are used as raw materials for other departments, so we have a chain of reports. Notice that the units and costs transferred out of Process 1 are the same as the units and costs transferred in to Process 2, and so on. I hope this helps. Call, e-mail, write, or fax me any time! 16-63 BYP 16-6 RESEARCH ASSIGNMENT (a) Proview International earns just 21/2 cents on every dollar of sales— that is, its profit margin ratio is 2.5%. It is so thin because the technology has not changed much, thus it is very difficult for competitors to differentiate their products. (b) The company has taken the following steps to control costs: i. ii. iii. iv. v. vi. vii. viii. It was one of the first electronics companies to build a plant in China. It buys its key components from a single source, thus increasing its buying power. This has resulted in price discounts and delivery priority. It makes monitors for a dozen different companies, thus expanding its volume and increasing its ability to buy parts inexpensively. By producing in large volumes it is able to take advantage of economies of scale in its manufacturing processes. It gives customers a new monitor if theirs breaks, rather than fixing it in the U.S. Then it ships the broken monitor back to China. This saves money because it is relatively cheap to ship goods to China from the U.S. compared to the cost of shipping goods from China to the U.S., and the labor cost of repairing a monitor is much lower in China. It uses a single chassis for over 300 different monitor models. This provides significant savings in materials costs as well as delivery flexibility. It has begun to “vertically integrate” by buying a key supplier of one of its main components—the deflection yoke. This saves it $1.50 per monitor. it built its own “clean room” for assembling LCD monitors. This reduced its cost by $8 per monitor. (c) It continues to build tube-based monitors because it believes that its ability to be the low-cost provider will provide it with profits as long as some people continue to buy these monitors. It expects that even though the market for tube-based monitors is shrinking, its share of the market will continue to increase as others leave the market. 16-64 BYP 16-6 (Continued) (d) Mr. Wang’s final comment is that cost is the most important aspect of its business. This is true because it has such thin profit margins and operates in such a competitive environment. It can’t raise its prices, thus it must be constantly vigilant about cutting costs. 16-65 BYP 16-7 ETHICS CASE (a) The stakeholders in this situation are: Barb Crusmer, molding department head. Wayne Terrago, quality control inspector. Customers of C. C. Daibo Company. The department manager of the assembly department. (b) Wayne is placed in an ethical dilemma. He can offend his department head by disregarding Barb’s instructions and lose the support of his supervisor, maybe his job. He can follow Barb’s instructions and be in violation of company policy. He can also report Barb’s instructions to supervisors (plant superintendent or vice-president of production). The company should make the position of quality control inspector responsible to someone other than the department head. Wayne should not report to Barb. 16-66