File

Interrelationship among design, materials, and processing

1

Example No. 01: Design of a Mild Steel

The yield strength of mild steel with an average grain size of

0.05 rom is 20,000 psi. The yield stress of the same steel with a grain size of 0.007 mm is 40,000 psi. What will be the average grain size of the same steel with a yield stress of 30,000 psi?

Assume the Hall-Petch equation is valid and that changes in the observed yield stress are due to changes in grain size.

Solution:

σ y

=

σ

0

+ Kd -1/2

Where σ y

is the yield strength, d is the average dia of the grains, and σ

0 and K are the constants for the metal.

Thus, for a grain size of 0.05 mm the yield stress is

20 x 6.895 MPa = 137.9 MPa.

(Note: 1,000 psi = 6.895 MPa). Using the Hall-Petch equation

137.9 =

σ

0

+ K / √0.05

For the grain size of 0.007 mm, the yield stress is 40 x 6.895 MPa =

275.8 MPa. Therefore, again using the Hall-Petch equation:

275.8 =

σ

0

+ K / √0.007

Solving these two equations K = 18.43 MPa_mm

σ y

= 55.5 + Kd

I

/

2

, and σ

0

=

55.5 MPa. Now we have the Hall-Petch equation as

-1/2

If we want a yield stress of 30,000 psi or 30 x 6.895 = 206.9 MPa, the grain size will be 0.0148 mm or 14.8 µ-m.

2

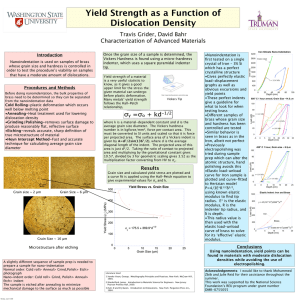

The Effect of grain size on the yield strength of steel at room temperature

3