solution set 3

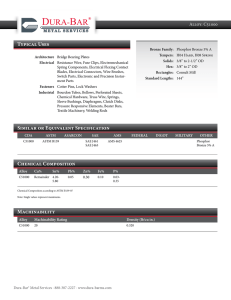

advertisement

1. Core 8.01 0.75 “ 0.05082” A0 = (0.75in)(0.05082in) = 0.03816in 2 FMAX = 10,000 lbs 10,000lbs ! MAX = = 262ksi 0.03816in 2 ! MAX = 262 > ! T = 65 Thus the tensile testing machine has the capacity to break tensile bars of this steel. 2. Core 8.05 σ 180 160 140 120 100 80 60 E=12000 ksi 40 20 0.02 0.04 0.06 0.08 0.10 0.12 ε 0.002 Note that there is no single absolutely correct answer. One does not now at what strain the curve reaches 180 ksi nor at what stress the curve ends when it reaches an elongation of 12%. 3. Core 8.12 4. Core 8.34 5. Core 8.21 6. Callister 7.21 Briefly explain why HCP metals are typically more brittle than FCC and BCC metals. 7. Callister 7.24 The lower yield point for an iron that has an average grain diameter of 1 " 10!2 mm is 230 MPa (33,000 psi). At a grain diameter of 6 " 10!3 mm , the yield point increases to 275 MPa (40,000 psi). At what grain diameter will the lower yield point be 310 MPa (45,000 psi)? 8. Callister 7.29 Two previously undeformed specimens of the same metal are to be plastically deformed by reducing their cross-sectional areas. One has a circular cross section, and the other is rectangular; during deformation the circular cross section is to remain circular, and the rectangular is to remain as such. Their original and deformed dimensions are as follows: Circular (diameter, mm) Rectangular (mm) Original dimensions 18.0 20 x 50 Deformed dimensions 15.9 13.7 x 55.1 Which of these specimens will be the hardest after plastic deformation, and why? 9. Callister 8.9 Calculate the maximum internal crack length allowable for a Ti-6Al-4V titanium alloy (Table 8.1) component that is loaded to a stress one-half of its yield strength. Assume that the value of Y is 1.50. 10. Callister 8.10 A structural component in the form of a wide plate is to be fabricated from a steel alloy that has a plane strain fracture toughness of 98.9 MPa m (90 ksi in ) and a yield strength of 860 MPa (125,000 psi). The flaw size resolution limit of the flaw detection apparatus is 3.0 mm (0.12 in.). If the design stress is one-half of the yield strength and the value of Y is 1.0, determine whether or not a critical flaw for this plate is subject to detection. 11. Callister 8.20 The fatigue data for a steel alloy are given as follows: Stress Amplitude [MPa (ksi)] 470 (68.0) 440 (63.4) 390 (56.2) 350 (51.0) 310 (45.3) 290 (42.2) 290 (42.2) 290 (42.2) Cycles to Failure 104 3! 104 105 3! 105 106 3! 106 107 108 12. Core 8.33