Yield Strength as a Function of Dislocation Density Travis Grider, David Bahr

advertisement

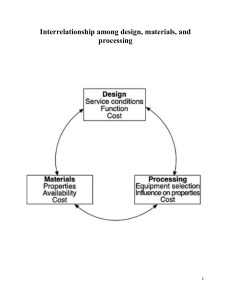

Yield Strength as a Function of Dislocation Density Travis Grider, David Bahr Characterization of Advanced Materials Introduction Nanoindentation is used on samples of brass whose grain size and hardness is controlled in order to test the procedure’s viability on samples that have a moderate amount of dislocations. Procedures and Methods Before doing nanoindentation, the bulk properties of brass need to be determined so they can be separated from the nanoindentation data . Cold Rolling-plastic deformation which occurs well below melting point •Annealing-Heat treatment used for lowering dislocation density •Grinding/Polishing-removes surface damage to produce reasonably flat, reflective surface •Etching-reveals accurate, sharp definition of true microstructure of material •Heyn Intercept Method-Fast and accurate technique for calculating average grain size diameter Once the grain size of a sample is determined, the Vickers Hardness is found using a micro-hardness indenter, which uses a square pyramidal indenter tip. Yield strength of a material is a very useful statistic to know, as it gives a good upper limit for the stress the given material can undergo before plastic deformation. Many metals’ yield strength follows the Hall-Petch relationship, http://www.hardnesstesters.com/vickers.jpg Vickers Tip where k is a material-dependent constant and d is the average grain size diameter. The Vickers hardness number is in kgforce/mm2, force per contact area. This must be converted to SI units and scaled so that it is force per projected area. The surface area of a Vickers indent is given by A=d2/2sin(136°/2), where d is the average diagonal length of the indent. The projected area of this area is just d2/2. Taking the ratio of contact to projected area and multiplying by the gravitational constant gives 10.57, divided by 3 for geometric scaling gives 3.52 as the multiplication factor converting from HV to σy. Results 20 μm 10 μm Grain size ~ 2 μm Grain size and calculated yield stress are plotted and a curve fit is applied using the Hall-Petch equation to give experimental values for σo and k. Grain Size ~ 6 μm 100 μm Grain Size ~ 16 μm Monday, July 27, 2009 τ = 3250 MPa τ=440 MPa τ=510 MPa τ=360 MPa τ=220 MPa τ=190 MPa Conclusions Microstructure after etching A slightly different sequence of sample prep is needed to prepare a sample for nano-indentation Normal order: Cold roll> Anneal> Grind,Polish> Etch> photograph Nano-indent order: Cold roll> Grind, Polish> Anneal> Etch> indent The sample is etched after annealing to minimize mechanical damage to the surface as much as possible •Nanoindentation is first tested on a single crystal of Iron – 3% Si which has a perfect crystalline structure •Gives perfectly elastic load-displacement graphs as well as obvious excursions and yield points •These perfect indents give a guideline for what to look for when testing brass •Different samples of brass whose grain size and hardness has been controlled are tested •Similar behavior is seen in brass as in the Iron, albeit not perfect •Previously electropolishing was tried during sample prep which can alter the atomic structure, hand polishing avoids this •Elastic load-unload curve for Iron sample is plotted and curve-fitted to Hertzian model P=4/3E*R1/2δ3/2, using known elastic modulus to find tip radius. E* is the elastic modulus, R is the indenter tip radius, and δ is depth. •This radius value is then used with the elastic load-unload curve of brass to solve for its ‘effective’ elastic modulus. Using nanoindentation, yield points can be found in materials with moderate dislocation densities while avoiding the use of electropolishing. Literature Used 1.Vander Voort, George. Metallography Principles and Practices. New York: McGraw-Hill, 1984. 2.Shackelford, James. Introduction to Materials Science for Engineers. New Jersey: Pearson Prentice Hall, 2009. 3.Hull, D and D J Bacon. Introduction to Dislocations. New York: Pergamon Press Inc., 1984. Acknowledgements: I would like to thank Mohammed Zbib and Julie Reid for their assistance throughout the summer. This work was supported by the National Science Foundation’s REU program under grant number DMR-0755055