Power Screws - University of Nairobi

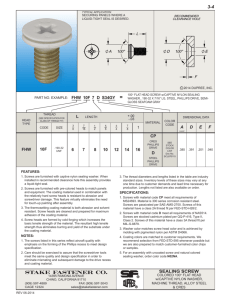

advertisement

POWER SCREWS APPLICATION OF POWER SCREWS The function of a power screw is to provide a means for obtaining a large mechanical advantage and at the same time transmitting power by converting angular, into linear motion. Common applications include lifting jacks, presses, vices, and lead screws for lathe machines. Figure 1.1 shows the application in a lifting jack, while Figure 1.2 shows the same concept when used for a press. SCREW JACK APPLICATION SCREW PRESS APPLICATION University of Nairobi Engineering Design Power screws THREAD FORMS FOR POWER SCREWS Power screws use either square, or trapezoidal thread forms. Two types of trapezoidal thread forms are the ACME thread standard, used widely in the English speaking countries, and based on the inches units, and the Metric trapezoidal standard, originating in Europe, and now adopted by the International Standards Organisation (ISO). Figure 1.3 shows the three geometric profiles of the three thread forms used for power screws. The (ISO) Metric trapezoidal thread form standard includes specifications that relate screw shaft diameter to pitch, as shown in Table 1.1. For the square and ACME thread form standards, only the geometric profile of the thread form is specified, and the designer is left to chose the size of thread for each screw shaft diameter. This does not pose any serious problem because each power screw application is often a special case. Table 1.1: (ISO) Metric Trapezoidal screw thread standards-Diameter and Pitch specifications Nominal (Major Exernal) Diameter d 8 10 12 16 20 24 28 32 36 40 44 48 52 60 Nyangasi Coarse Medium Fine Pitch Diameter d 2 D2 8 8 10 10 10 12 12 12 14 1.5 2 3 4 4 5 5 6 6 7 7 8 8 9 1.5 2 2 2 3 3 3 3 3 3 3 3 3 7.25 9.00 10.50 14.00 18.00 21.50 25.50 29.00 33.00 36.50 40.50 44.00 48.00 55.50 Pitch p 8 March, 2016 Major Internal Diameter D Minor Diameter External d1 Internal D1 8.30 10.50 12.50 16.50 20.50 24.50 28.50 33.00 37.00 41.00 45.00 49.00 53.00 61.00 6.20 7.50 8.50 11.50 15.50 18.50 22.50 25.00 29.00 32.00 36.00 39.00 43.00 50.00 6.50 8.00 9.00 12.00 16.00 19.00 23.00 26.00 30.00 33.00 37.00 40.00 44.00 51.00 Page 2 of 10 University of Nairobi Engineering Design Power screws Figure 1.4 illustrates the dimensions of the (ISO) Metric Trapezoidal thread standard shown in Table 1.1. MECHANICS OF POWER SCREW (SQUARE THREADED) Figure 1.5 shows the geometry and dimensions of a square threaded power screw, with a single start thread. The power screw carries an axial load F, and this is to be raised or lowered by applying a turning moment or torque on the screw shaft. The screw and nut machine then coverts the torque on the screw shaft, into the desired axial load. This is the typical situation in the screw jack, and the screw press concepts shown at Figures 1.1 and 1.2. Nyangasi 8 March, 2016 Page 3 of 10 University of Nairobi Engineering Design Power screws The axial load F applied on the screw shaft is resisted by an equal and opposite force acting on the nut. The rest of the variables in Figure 1.5 are: F Axial Load to be raised or lowered Helix angle for thread p Pitch of thread d m Mean diameter of screw thread dm D1 d 2 EXTERNAL LOAD ON SCREW SHAFT TORQUE REQUIRED IN A SQUARE THREADED POWER SCREW It is necessary to determine the torque required in a power screw, as a function of the axial load to be raised or lowered, because this torque comprises one of the external loads that the screw shaft and its threads must withstand. This torque load is found to be a function of the axial load F, the geometry and dimensions of the screw shaft and its threads, and the coefficient of friction between screw and nut threads. TORQUE TO RAISE AXIAL LOAD WITH SQUARE THREAD FORM To determine the relationships between the torque required, and the axial load to be raised F, the screw thread is simplified into an inclined plane. Figure 1.6 shows a single thread of the screw, unrolled or developed, to show the forces operating on the thread surface when the load F is being raised. The axial load F is then considered as representing the summation of all the unit forces acting on the direction of the axial load to be raised. In Figure 1.6, the horizontal force P is the resultant force arising out of the applied torque. It operates to move the axial load F, along the inclined plane formed by the developed thread surface. Nyangasi 8 March, 2016 Page 4 of 10 University of Nairobi Engineering Design Power screws Although the unit forces, whose summation is F and P, act on the entire thread surface between minor internal diameter D1 and the major external diameter d , the resultant forces are simplified to be concentrated at the mean of the two diameters d m D1 d . For single 2 start thread, the inclined plane, along which the load F is moved, is therefore a triangle whose angle of inclination is the helix angle of the screw thread defined by tan l d m The length of the side opposite to the lead angle is equal to the lead l of the screw thread. The base of the triangle is equal to the circumference of the mean thread diameter, which equals d m . The triangle at Figure 1.6 applies to one turn of a thread, but is similar to the case of the entire length of engaged threads. The forces F and P can therefore represent the summation of forces on the entire surface of the engaged threads. In reaction to the forces F and P, operating on the surface of the threads, there is a normal force N, and a frictional resistance given by the expression * N . The unknown forces in this system of forces can be determined as shown below, by the requirements of equilibrium: Fh P N sin N cos 0 Fv F N sin N cos 0 Where Fh Horizontal ; forces Fv Vertical forces Solving the two equations for F and P, Solving the two equations for F and P P N sin N cos F N cos N sin Substituting for tan l d m l d m and P F d m l But the torque resulting from the force P, is the product of P and the mean radius dm at which the force P is presumed to act. Consequently, the torque T is given by the 2 expression: T Nyangasi F dm 2 l d m d m l 8 March, 2016 Page 5 of 10 University of Nairobi Engineering Design Power screws THE CASE OF ANGULAR THREAD FORM The equation for the torque required on the screw shaft to raise an axial load F, has been derived, and is therefore valid, for the square thread form, where the normal thread loads are parallel to the axis of the screw shaft. In the case of an angular thread form, such as ACME, (ISO) Metric Trapezoidal or other angular thread forms used in fasteners, the thread angle for the various thread forms is as shown in the table below: Thread Form ACME (ISO) Metric Trapezoidal Metric Fasteners Thread angle =2* in degrees 29 30 30 In these angular thread forms, the load normal to thread surface is inclined to the axis of the screw shaft by an angle , or half the thread angle. This is illustrated at Figure 1.7. The effect of this inclination to the axis of the screw shaft of the normal load on thread surface is to increase the frictional force on the thread surface, by the wedging action of the threads. The frictional force is increased by a factor equal to the reciprocal of cos . To account for this increased frictional force, the frictional terms in the torque equation are divided by cos . The equation for the torque required when raising an axial load F, where the screw thread form has a thread angle of 2*, therefore becomes: T Nyangasi Fd m 2 l d m sec d m l sec 8 March, 2016 Page 6 of 10 University of Nairobi Engineering Design Power screws TORQUE REQUIRED TO LOWER LOAD From the force diagram in Figure 1.6, it is seen that when raising an axial load F, the force P (and hence the torque T), has to overcome both the axial load F, as well as the friction on the thread surface. However, when lowering the axial load F, the axial load F itself assists the torque T to overcome the thread friction. The torque required to lower load is therefore given by the expressions: 1. Square thread form -Torque to lower load T Fd m 2 l d m d m l 2. Angular thread form -Torque to lower load T Fd m l d m sec 2 d m l sec TORQUE TO OVERCOME COLLAR FRICTION In most applications, the axial load F must be transmitted through a thrust collar. This is necessary so that when operating the screw shaft, the collar pad may remain stationary with the load being lifted, or work to be pressed, while the screw shaft rotates, as shown in Figure 1.8. For this reason, an additional friction force appears at the collar pad, and the external torque applied to operate the power screw shaft must also overcome this extra force, which gives rise to an extra friction torque. Nyangasi 8 March, 2016 Page 7 of 10 University of Nairobi Engineering Design Power screws Figure 1.8 shows a typical thrust collar arrangement, with the thrust load assumed to be concentrated at the mean collar diameter. The torque required to overcome collar friction is then given approximately by the expression: F c d c , Where, 2 F Axial load to be raised , c Co efficient of collar friction Tc di do (approximately ) 2 d i Inner diameter of collar , d o Outer diameter of collar d c Mean collar diameter, d c Tc Torque to overcome collar friction For large collars, the friction torque at collar bearing will be more accurately computed as for a disc clutch. Nyangasi 8 March, 2016 Page 8 of 10 University of Nairobi Engineering Design Power screws THREAD STRESSES These are given by the expressions: s 2F , d1 h n 2F , dh b 4 pF h(d 2 d1 2 ) Where, h Height of nut , and p pitch of screw threads s Average shear stress on screw threads n Average shear stress on nut threads Bearing stress on thread surfaces b When these thread stresses are computed, they should not exceed the limiting values for the chosen materials. ALLOWABLE BEARING PRESSURES Limiting values of bearing pressures on thread surfaces for various combination of screw and nut material have been determined empirically and are found to be as shown in Table 1.2. TABLE 1.2: SAFE BEARING PRESSURES FOR POWER SCREWS Type of Power Screw Screw Material Hand press Jack-screw Jack-screw Hoisting screw Hoisting screw Lead screw Steel Steel Steel Steel Steel Steel Nut Bronze Cast iron Bronze Cast iron Bronze Bronze Safe Bearing Pressure N / mm 2 17.0-24.0 12.0-17.0 11.0-17.0 4.0-7.0 5.5-10.0 1.0-1.6 Rubbing speed in m / s Low speed, well lubricated Low speed <2.5 Low speed<3 Medium speed (6-12) Medium speed (6-12) High speed>15 DESIGN PROCEDURE FOR SCREW SHAFT AND NUT After determining the torque required to raise axial load F, and the extra value required to overcome collar friction, all the external loads on the screw element are known, and the screw shaft can then be analysed for its ability to resist these forces. Similarly, the same forces act on the nut, and this element can also therefore be analysed for strength. In the examples of the lifting jack and screw press shown at Figures 1.1 and 1.2, the screw and nut elements can be designed without considering the frame arrangements. In this case therefore, the steps listed below are appropriate in the design of screw shaft and nut. Nyangasi 8 March, 2016 Page 9 of 10 University of Nairobi Engineering Design Power screws (a) Select the material and thread form for the screw; (b) Decide on the type and material for thrust bearing; (c) If column failure is a possibility, determine required diameter of screw shaft based on this requirement; otherwise select a trial screw shaft diameter with strength to withstand stresses due to axial load only. (d) Using the screw shaft diameter from ©, determine thread dimensions, and stresses on screw shaft, (namely, axial, bending, and torsional. (e) Compare stresses induced in screw shaft with strength of material selected; (f) Select new screw shaft diameter, if factor of safety is inadequate; (g) Determine thread stresses and confirm factor of safety adequate; CONDITION FOR SELF LOCKING For the square threaded screw, the torque required to lower load is seen to vary with the lead of screw thread according to the expression: Fd m 2 T l d m l d m Ignoring collar friction and equating the torque to zero, gives the limiting conditions at which the load F will cause the thread to operate and lower itself, without any external torque. The limiting value of the lead at which the screw ceases to be self locking therefore becomes: Fd m l d m 0, or d m l 2 l d m l and tan d m T Thus the limiting condition for self-locking for a square threaded screw is when the coefficient of friction between thread and nut surfaces equals the tangent of the lead or helix angle. Self-locking ceases when the tangent of the helix angle is greater than the co-efficient of friction. Self locking ceases when tan EFFICIENCY OF SCREW This is given by the expression: e F *l , 2T Where e efficiency of screw For a square threaded screw, without collar friction, the efficiency becomes: e l d m Nyangasi d m l d m l 8 March, 2016 Page 10 of 10