COURSE CODE MEC 2 0 9 COURSE TITLE DESIGN OF MACHINE

advertisement

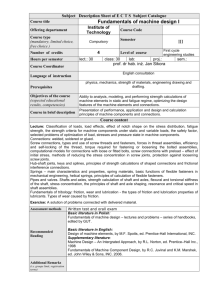

COURSE CODE M E C 2 0 9 COURSE TITLE DESIGN OF MACHINE ELEMENTS- I WEIGHTAGES L T P CREDITS (or Max. Marks) 3 1 2 5 CA MTE ETE Attd. AT P P Th P Th 5 20 20 0 15 0 40 COURSE OBJECTIVES: To impart basic designing skills to the students having no prior exposure to designing PRE-REQUISITES: Mechanics of solids, Material Science COURSE CONTENTS: S. No. 1 2 3 4 5 6 7 8 Description INTRODUCTION: Machine Design, Basic procedure of machine design, Basic requirements of machine elements, Design of machine elements, Traditional Design Methods, Design synthesis, Use of standards in design, Selection of preferred sizes ,Aesthetic consideration in design, Ergonomic considerations in design, Concurrent engineering. MANUFACTURING CONSIDERATIONS IN DESIGN: Selection of manufacturing method, Design consideration of casting, forging and machined parts, Hot and cold working of metals, Design considerations of welded assemblies, Design for manufacture and assembly, tolerances, Types of fits, BIS system of fits and tolerances, Selection of fits, Tolerances and manufacturing methods. DESIGN AGAINST STATIC LOAD: Modes of failure, factor of safety, Stress- strain relationship, Shear stress and shear strain, stresses due to bending moment, Stresses due to torsional moments, Eccentric Axial loading, Design of simple machine parts -Cotter joint, knuckle joint, Principal stresses, Theories of Elastic Failure, Maximum Principal stress theory, maximum shear stress theory, Distortional – energy theory, Selection and use of failure theories, levers , Design of levers, Fracture mechanics, Curved beams, thermal stresses, residual stresses DESIGN AGAINST FLUCTUATING LOAD: Stress concentration, stress concentration factor, reduction of stress concentration, fluctuating stresses, fatigue failure endurance limit, notch sensitivity, reversed stresses- design for finite and infinite life, cumulative damage in fatigue, Soderberg and Goodman lines, modified Goodman diagrams, Gerber equation, fatigue design under combined stresses, impact stresses. MTE POWER SCREW: Power screw, forms of Screw Threads, Multiple Threads, Terminology of threaded screw, Torque Requirement- lifting load, torque requirement – lowering load, self locking screw, Efficiency of Square Threaded Screws, Efficiency of Self Locking Screws, Acme or Trapezoidal Threads, collar friction torque, overall efficiency, Coefficient of friction, design of screw and nuts, design of screw jack, Differential and Compound Screws, recirculating ball screw THREADED JOINTS: Threaded joints, basic types of screw fastening, Cap screws, setscrews, Bolt an of uniform strength, locking devices, terminology of screw thread, ISO metric screw threads, Material and manufacture, bolted joint, torque requirement for bolt tightening, dimensions of fasteners. WELDED AND RIVETED JOINTS: welded joints, riveted joints. DESIGN OF SHAFTS: Transmission shaft, shaft design on strength basis, shaft design on torsional rigidity basis, ASME code for shaft design, flexible shafts, keys, types of keys, coupling, types of coupling and design procedures of couplings, design of lateral rigidity, Castigliano’s theorem, area moment method, graphical integration method,critical speed for shaft. TEXTBOOK: 1.V.B. BHANDARI, DESIGN OF MACHINE ELEMENTS, 3rd edition. ADDITIONAL READING: 1. Shigley, Design of Machine Element, McGraw Hill 2. Design data Book by PSG, Coimbatore rd 3. Fundamentals of Machine Component Design Robert C. Junivall/Kurt, 3 edition Wiley 4. R. Norton, Machine Design, An Engineering Approach, Pearson LAB CONTENTS:Expt. No. 1 2 3 4 5 6 7 8 9 10 11 Title* Introduction to basic commands used in pro-E. Introduction to common commands in sketcher module. Introduction of general tools in solid modelling. Drawing different 3-D objects using extrude command. Drawing objects using revolution command. Drawing objects using sweep, blend and swept blend. Assembly of parts in assembly module. Drawing of assembled parts in drawing module. Small project :Design and manufacturing using pro-e software(one project to each students) Small project :Design and manufacturing using pro-e software(one project to each students) Small project :Design and manufacturing using pro-e software(one project to each students) SALIENT PEDAGOGICAL FEATURES: 1. More focus should be given on improving basics of design because students are assumed to have no prior exposure to designing.