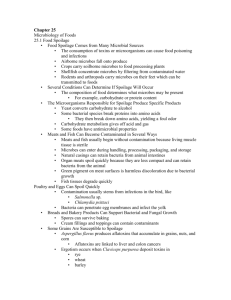

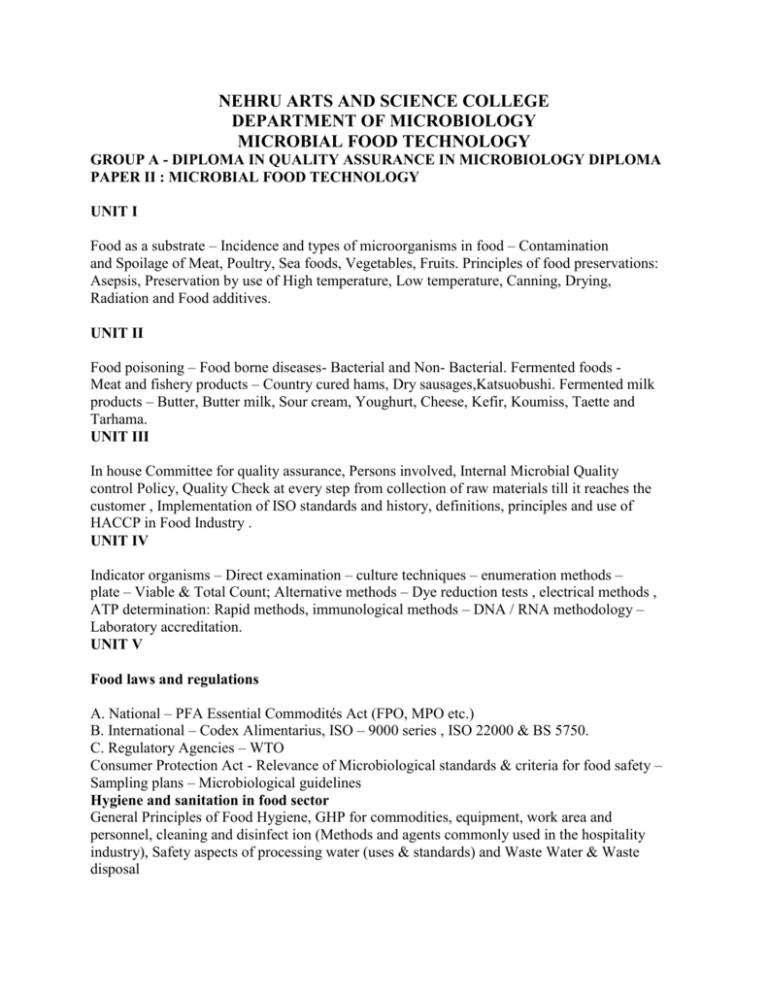

microbial food technology 2011 final - E

advertisement