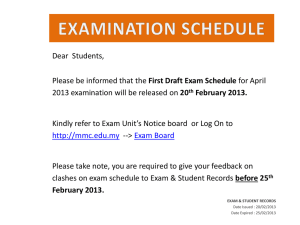

contains

advertisement