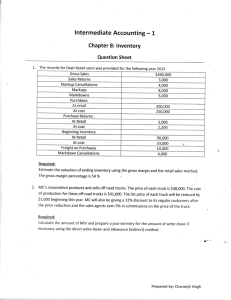

Operations Management: Chapter 1 - Introduction & Key Concepts

advertisement