Commonwealth of Pennsylvania PA Test Method No. 630

advertisement

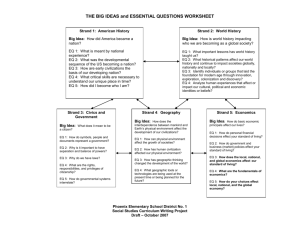

Commonwealth of Pennsylvania Department of Transportation PA Test Method No. 630 October 2013 8 Pages LABORATORY TESTING SECTION Method of Test for ASSESSMENT OF CONCRETE TO STRAND BOND FOR PRESTRESSED APPLICATIONS 1. SCOPE 1.1 This test method examines bond quality of seven-wire strand used in prestressed concrete applications by means of a destructive pullout test of a strand from a concrete prism. The method is developed for examination of both strand quality and concrete bond properties. 1.2 This test method is applicable primarily under field conditions; however, controlled laboratory tests are also appropriate. 1.3 The values stated in this test method are in pounds and inches unless otherwise noted. 2. REFERENCED DOCUMENTS 2.1 ASTM International. “C 39/C 39 – Compressive Strength of Cylindrical Concrete Specimens,” West Conshohocken, PA: 2004. . 2.2 ACI 318-02, Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute, 2002. 2.3 PCI, “PCI Design Handbook,” Precast and Prestressed Concrete, Fifth Edition, Chicago, IL, 1999 3. SIGNIFICANCE AND USE 3.1 This test method is intended to be used to assess the adequacy of bond between concrete and seven wire prestressing strand using production concrete mixes and as-delivered strand under plant fabrication conditions. The test method allows for identification of potential bond problems due to changes in strand surface conditions, concrete mix proportions, or concrete constituents. The test method is intended for use by a precast/prestress plant to allow for initial mix design verification or initial strand supplier qualification prior to use in full production. The test would be performed during the mix prequalification phase. The test is not intended to be used during production. PTM No. 630 October 2013 Page 2 4. APPARATUS 4.1. Molds for Test Specimens- The molds for the test specimen shall measure 6.5-in. wide by 12-in. deep (Figure 1). The specimen length is equal to the bonded length, Lb, plus an additional 2-in. un-bonded length. The bonded lengths are tabulated relative to different strand diameters in Table 1. The molds shall be made of steel or wood and allow for easy removal after fabrication. The molds shall be made watertight after assembly around the prestressed strand. Special care shall be taken to seal areas where the strand extends from the mold. The molds shall be designed to hold the strand at the center of the cross-section. Table 1: Specimen Bond Length Strand Designation Bond Length, Lb [in.] PCI* Specimen Length [in.] 3/16 22 24 7/16 26 28 1/2 30 32 1/2 Special 32 34 9/16 34 36 0.60 36 38 *Calculated per PCI Bridge Design Manual (8.3.1.5) using 60 strand diameters End Elevation Side Elevation Figure 1: Test Specimen 4.2 Measuring Apparatus- The movement of the strand with respect to the concrete shall be measured on the rear (dead) end. A dial gage or displacement transducer with a graduation of 0.001-in. and a minimum stroke of 0.5-in. shall be used. The load shall be measured with a calibrated load cell in-line with the strand being tested. Use of a jack pressure gage is not recommended unless the gage has been calibrated with a load cell and is capable of providing a resolution of +/- 20 lbs. A suitable displacement measuring apparatus is shown in Figure 2. PTM No. 630 October 2013 Page 3 Figure 2: Measuring apparatus 4.3. Testing Apparatus - The testing apparatus shall consist of a through-hole hydraulic jack or universal testing machine, a reusable strand chuck, and a bearing plate. The bearing plate shall have an adequate bearing area to prevent crushing of the concrete surface. The hydraulic jack shall have a controller that allows for a smooth load increase of 20 kips/min. A schematic of a usable testing configuration is shown in Figure 3. The jack shall have a minimum stroke of 4-in. to allow for full pullout. Figure 3: Test apparatus 5. TEST SPECIMEN 5.1 The test specimens shall be cast in a horizontal orientation on the precast plant prestressing bed around the stressed strand. An initial jacking stress of 75% of the strand ultimate strength is recommended. For example, for a 270 ksi ½-in. special strand a jacking force of 33.8 kips is recommended. No additional reinforcement shall be used. If possible, the specimens shall be situated at the end of the strand run, inline with the precast element that is being fabricated. Adequate free strand length shall be provided on the un-bonded end to allow for jacking (a length of 40 in. is recommended). A minimum of three specimens shall be fabricated for each combination of strand type and concrete mix design. All specimens shall be cast from the same batch of concrete using the same strand lot, within one (1) hour of each other and cured together. PTM No. 630 October 2013 Page 4 5.2 Concrete shall be placed and vibrated using form or immersion-type vibrators. For self consolidating concrete mixes (slump > 10-in.) placement can be conducted in one lift without consolidation. Once the mold is filled, the top surface shall be finished with a steel trowel and covered to prevent loss of moisture. Curing methods shall conform to standard plant practice. 5.3 A minimum of six companion concrete cylinders, 4-in. by 8-in. or 6-in. by 12-in., shall be fabricated and tested according to ASTM C 39 to determine the compressive strength of the concrete at transfer and at the time of testing. The cylinders will be match cast and match cured with the specimens to ensure consistency between the specimen and cylinder strengths. 5.4 The initial prestress shall be transferred in accordance with plant procedures. Slow transfer of stress is recommended; however, flame cutting of strands can be used. 5.5 The release strength of the concrete shall conform to the design application. Initial testing, for the purpose of developing historical data of accepted and/or approved mix designs used for prestressed concrete beams must be performed when the concrete compressive strength at release is not less than 6800 psi or greater than 7500 psi. That strength is to be verified before release in accordance with the plant's normal procedures. 5.6 After release of prestress the strand shall be cut flush with the surface of the specimen at the dead end and a 40-in. length of strand shall be left on the live end (debonded side). The cut side shall be ground flat with an abrasive wheel to provide a smooth bearing surface for the displacement measurements. 5.7 Testing of the specimens shall take place within two (2) hours after release. Pullout tests of the three specimens shall be conducted sequentially over a duration of less than one (1) hour to ensure consistency in concrete strengths. 6. PROCEDURE 6.1 The specimens shall be tested in the horizontal position. The displacement gage shall be attached to the strand at the dead end of the specimen as shown in Figure 3. At the dead end of the specimen the displacement gage shall be attached to one of the outer strand wires. Avoid the inner wire as relative slip may occur between the inner and outer wires of the strand resulting in an inaccurate measurement. 6.2 The jack and bearing plates shall be supported with blocking prior to loading to ensure that the strand is centered in the test setup. Apply a load at a maximum rate of 20 kips/min., or if displacement control of the ram is available, at a rate less than 0.02 in./min. Take proper safety precautions against potential flying debris that may be generated during failures. Safety guidelines are beyond the scope of this document and shall be discussed with the plant safety committee prior to use. PTM No. 630 October 2013 Page 5 6.3 Record the applied load (in pounds) and displacements regularly such that a minimum of 10 points are recorded prior to a dead end displacement of 0.01-inch. Record the load to the nearest pound and the displacement to the nearest 0.001-inch. Be careful to note the load level when the dead end reaches a displacement of 0.01-inch, Fi, and 0.1-inch, Fu. Continue recording until: 1) a decrease in load by 25% is measured, 2) the strand fractures, or 3) a displacement of 0.5-in. is measured on the live end. 7. CALCULATION 7.1 Bond quality is computed relative to lower bound transfer and development lengths measured for the chosen concrete properties and strand type. The lower bound estimate of transfer length is computed according to Equation 1. The lower bound bond length required to achieve the fracture strength of the strand can be computed according to Equation 2. Lti = Lower bound transfer length [in.] Lult = Lower bound bond length required to fracture strand [in.] fpi = Initial stress in strand at transfer [ksi] fpu = Ultimate strength of strand [ksi] Fi = Measured force corresponding to 0.01-in. slip at dead end of specimen [kips] Fu = Measured force corresponding to 0.10-in. slip at dead end of specimen [kips] 2 As = Cross-sectional area of strand [in. ] Lb = Bonded length of strand [in.] PTM No. 630 October 2013 Page 6 7.2 To compare the bond qualities of the results with concretes of different strengths, compute a normalized transfer and ultimate bond length. Normalize the lengths relative to the tensile concrete strength by dividing the computed lengths by the square root of the concrete compressive strength as shown in Equations 3 and 4. f’c = Concrete compressive strength measured at the time of the pullout test [psi] 8. REPORT 8.1 Include in the report the following information: • • • • • • • • • • • • • • • • • • • • Date and Time of Concrete Placement Date and Time of Stress Transfer Date and Time of Pullout Test Concrete Mix Batch Weights Mix Design Identification No. Concrete Constituents Strand Size and Type Strand Manufacturer Strand Heat Number and Lot ID Strand Yield Strength [ksi] (from mill certification) Strand Ultimate Strength [ksi] (from mill certification) Concrete Compressive Strength at Release [psi] (average and standard deviation) Concrete Compressive Strength at time of Pullout Test [psi] (average and standard deviation) Initial Strand Jacking Stress [ksi] Strand Stress Prior to Transfer, fpi [ksi] Measured Pullout Force at Initial Slip, Fi [kips] per test Measured Maximum Pullout Force, Fu [kips] per test Failure mode Lower bound transfer and bond lengths Normalized transfer and bond lengths PTM No. 630 October 2013 Page 7 9. ACCEPTANCE 9.1 Until historical data is generated using this test method it is recommended that passing performance be assessed relative to the performance of historically good mixes. For example, to qualify a new self consolidating concrete (SCC) mix the following procedure can be adopted. The SCC shall be considered passing if the average of the three (3) tests is greater than 90% of the average of a high early strength (HES) concrete that has historically good performance. 9.2 With continued use of this test method it is expected that the results can be correlated directly with ACI/PCI transfer and development lengths. 10. ACKNOWLEDGMENTS 10.1 This test method was developed through a project financed by Schuylkill Products Inc. and a grant from the Commonwealth of Pennsylvania, Department of Community and Economic Development, through the Pennsylvania Infrastructure Technology Alliance (PITA) and through the support of, the Pennsylvania Department of Transportation, the Precast Association of Pennsylvania (PPA), and DeGussa Construction Chemicals. (PITA Project PIT-457-04, Dr. Clay Naito, Lehigh UniversityPrincipal Investigator). PTM No. 630 October 2013 Page 8 This page left intentionally blank