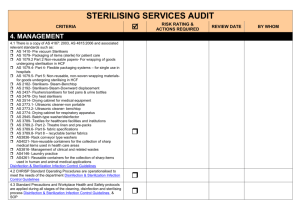

the asean guidelines for disinfection and sterilization of instruments

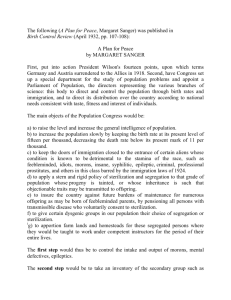

advertisement