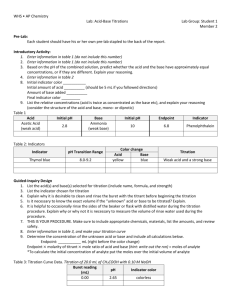

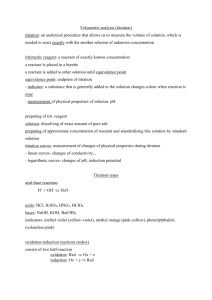

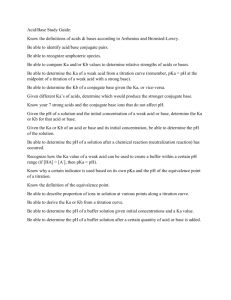

REDOX TITRATIONS Introduction

advertisement