SSTL_2 - 國立交通大學

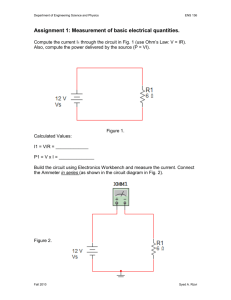

advertisement