Page 1 Tensile Test Tensile test is one of the most common tests for

advertisement

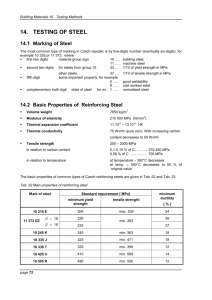

Tensile Test Tensile test is one of the most common tests for steel. The test is described by standard EN 10 002. The test involves straining a test piece by tensile force, generally to fracture, for the purpose of determining tensile strength, yield strength, event. ductility and reduction of area. 16.1.1 Definitions gauge length (L) - length of cylindrical or prismatic portion of the test piece on which elongation is measured at any moment during the test [m] original gauge length (L0) - gauge length before application of force [m] final gauge length (Lu) - gauge length after rupture of the test piece [m] elongation - increase in the original gauge length at the end of the test ductility – percentage elongation after fracture (A) - permanent elongation of the gauge length after fracture , expressed as the percentage of the original length: A= [%] Lu - L0 L0 extension – increase of the original length at a given moment of the test percentage reduction of area (Z) - maximum change of cross sectional area, which was occurred during the test, expressed as a percentage of the original cross-sectional area . Z= where S0 is Su S0 - S u S0 [%] original cross-sectional area before testing [m2] minimum cross-sectional area after fracture [m2] maximum force (Fm) - the greatest force which the test piece withstand during the test [N ] stress (σ) - force at any moment during the test divided by the original cross-sectional area (S0) of the test piece : σ= F S0 tensile strength (Rm) - stress, corresponding to the maximum force Fm : Rm = Fm S0 [MPa] yield strength (Ry) – when metallic material exhibits a yield phenomenon, a point is reached during the test at which plastic deformation occurs without any increase in the force : Ry = where Fy is [MPa] Fy S0 [MPa] force at the point of yield [N] proof strength (Rp) – stress at which extension is equal to a specified percentage of the gauge length. the symbol used is followed by a suffix giving the prescribed percentage,for example Rp, 0,2 page 1 Fig.:46 Stress –strain diagram a) steel with yield point b) steel with proof strength Rp,0,2 σ [N/mm2] σ [N/mm2] ( F [N] ) ( F [N] ) proof strength Rp,0,2 tensile strength Rm fracture Ry yield strenght elastic limit proportionality limit ε [-] ε [-] ( Δl [mm] ) 0,2 % ( Δl [mm] ) 16.1.2 Test Pieces The shape and dimensions of the test pieces depend on the shape and dimensions of the metallic products the mechanical properties of which are to be determined. The test piece is usually obtained by machining a sample from the product. However product of constant cross-section may be subjected to test without being machined. The cross section of the test pieces may be circular, square, rectangular, annular or, in special cases, of some other shape. 16.1.3 Determination of Original Cross-Section Area The original cross-section area S0 shall be calculated from measurements of the dimensions of the test piece. for products of circular cross-section and smooth surface S0 may be calculated from formula: S0 = π.d 2 4 [mm ] 2 where d is the arithmetic mean of two measurements carried out in two perpendicular direction for products of ribbed surface S0 may be determined from the mass of a known length L and its density (7850 kg/m3) according the formula : ρv = page 2 m m = V S0 × L and from it : S0 = m ρv × L [m ] 2 Vocabulary. strain deformace cold worked steel ocel tvářená zastudena ductility tažnost elongation prodloužení extension protažení final gauge length konečná měřená délka gauge length měřená (odměrná) délka grip pevně uchytit jaw čelist original gauge length počáteční měřená délka percentage elongation after fracture tažnost percentage reduction of the area stažnost (kontrakce) proof strength smluvní mez kluzu reinforcing steel betonářská ocel ribbed žebrovaný, s vroubkovaným povrchem stress napětí stress-strain diagram pracovní diagram weldability svařitelnost yield kluz, průtažnost yield strength mez kluzu page 3