Structure of non-graphitising carbons

advertisement

Structure of non-graphitising carbons

Published by Maney Publishing (c) IOM Communications Ltd

P. J. F. Harris

highly stable. It therefore seems worth considering

the idea that microporous non-graphitising carbons

may be fullerene-like in nature. Recent work has

provided support for this view by showing that high

temperature heat treatments can transform microporous carbons into fullerene like nanoparticles.15

The purpose of the present paper is to consider further

the evidence that non-graphitising carbons contain

fullerene related elements. In addition to microporous

carbons, a related class of non-graphitising carbon

known as glassy carbon will also be considered, and

a brief discussion will be given of the structure of

soot particles and carbon fibres. First, a brief outline

is given of the types of bonding found in carbon

materials. A description is then given of the preparation and properties of non-graphitising carbons,

and conventional models of their structure are critically discussed.

Despite many years of research, the detailed

atomic structure of many important carbon

materials remains poorly understood. In particular,

the structure of those carbons which can not be

transformed into graphite by high temperature

heat treatment has never been clearly established.

These non-graphitising carbons are of

considerable commercial importance in a variety

of fields, and a better understanding of their

structure is clearly needed. Recently, it has been

suggested that non-graphitising carbons may have

a microstructure which is related to that of

fullerenes. In the present paper, the evidence for

this will be considered in detail and the

advantages of the new model over previous

models of non-graphitising carbons will be

discussed. As well as microporous nongraphitising carbons, other forms of carbon

including glassy carbon and carbon fibres will be

considered.

IMRj304

Bonding in carbon materials

© 1997 The Institute of Materials and ASM International.

Dr P. J. F. Harris is based in the Department of Chemistry,

University

UK.

of Reading, Whiteknights,

Reading RG6 6AD,

Introduction

Although graphite is the most stable form of carbon

at normal temperatures and pressures, it is a remarkable fact that many carbons can not be transformed

into crystalline graphite even at temperatures of

3000°C and above. The so called 'non-graphitising'

carbons tend to be hard, low density materials, with

isotropic, microporous structures.1-6 In contrast, graphitising carbons are soft and non-porous, with densities much closer to that of crystalline graphite. Nongraphitising carbons can develop exceptionally high

surface areas when 'activated' by treatment with a

mild oxidising agent, and the resulting activated carbons are widely used as adsorbents and as catalyst

supports.4-6 Despite their commercial importance,

however, the detailed structure of these carbons at

the atomic level is still poorly understood. The traditional view is that the microstructure consists of

twisted networks of carbon layer planes crosslinked

by bridging groups, explaining both their hardness

and their resistance to graphitisation,2 but the precise

nature of such bridging groups has never been properly established. Earlier suggestions that Sp3bonding

may be present in non-graphitising carbons do not

appear to stand up to detailed analysis, as discussed

in the 'Problems with early models' section later.

The relatively recent discovery of the fullerenes,7-9

and subsequently of related structures such as carbon

nanotubes10-12 and nanoparticles,13,14 has given us

a new perspective on Sp2 bonded carbon structures.

Most importantly, we now know that carbon structures containing non-six membered rings can be

206

International

Materials Reviews

1997

Vol. 42

NO.5

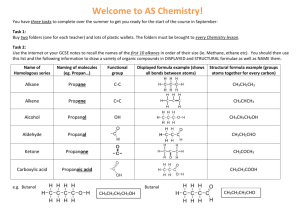

A free carbon atom has the electronic structure

Is2 2s2 2p2. In order to form covalent bonds, one of

the 2s electrons is promoted to 2p, and the orbitals

are then hybridised in one of three possible ways. In

graphite, one of the 2s electrons hybridises with two

of the 2p electrons to give three Sp2 orbitals at 120°

to each other in a plane, with the remaining orbital

having a pz configuration at 90° to this plane. The

Sp2orbitals form the strong (J bonds between carbon

atoms in the graphite planes, while pz or n orbitals

provide the weak van der Waals bonds between the

planes. In naturally occurring or high quality synthetic graphite, the stacking sequence of the layers is

generally ABAB, with an interlayer {0002} spacing

of approximately 0·334 nm, as shown in Fig. la. In less

perfect graphites, the interplanar spacing is found to

be significantly larger than the value for single crystal

graphite (typically ",0,344 nm), and the layer planes

are randomly rotated with respect to each other about

the e axis. Such graphites are termed turbostratic.

In the C60 molecule, shown in Fig. Ib, the carbon

atoms are bonded in an icosahedral structure made

up of 20 hexagons and 12 pentagons. Each of the

carbon atoms in C60 is joined to three neighbours, so

the bonding is essentially Sp2,although there may be

a small amount of Sp3character owing to the curvature. Note that all 60 carbon atoms are identical, so

that the strain is evenly distributed over the molecule.

Pentagonal rings are also present in carbon nanoparticles and nanotubes, although these generally have

much less perfect structures than those of C60 and

other fullerenes.

In diamond, each carbon atom is joined to four

neighbours in a tetrahedral structure, as shown in

Fig. le. The bonding here is Sp3,and results from the

mixing of one 2s and three 2p orbitals. Diamond is

less stable than graphite, and is converted to graphite

at a temperature of 1700°C at normal pressures.

Harris

a

Structure of non-graphitising

carbons

207

b

a graphite showing unit cell; b eso; c diamond

1

Illustration of bonding in carbon structures

Published by Maney Publishing (c) IOM Communications Ltd

Disordered carbons containing Sp3 bonded atoms

are also rapidly transformed into graphitic carbon at

high temperatures.

Non-graphitising carbons

Background

It has been known for about a century that some

carbon materials are more amenable to graphitisation

than others, but the first detailed study of graphitising

and non-graphitising

carbons was made by Rosalind

Franklin in the period before she began her famous

work on DNA. In a paper published in 1951,1

Franklin described XRD studies of the effect of high

temperature heat treatments on the structure of a

variety of carbons formed by pyrolysis of organic

materials. She found a clear distinction between carbons which could be converted into graphite by high

temperature annealing and those which could not.

Among the non-graphitising

carbons were those produced by the pyrolysis of polyvinylidene

chloride

(PVDC) and sucrose, while graphitising

carbons

included those made from polyvinyl chloride (PVC)

and petroleum coke. Franklin proposed structural

models for the two classes of carbon, and these will

be discussed in the next section.

Since Franklin's time there has been a vast amount

of research on the preparation and properties of nongraphitising carbons,2-s and only a very brief outline

is possible here. It is found that non-graphitising

carbons are invariably highly porous, although some

of this porosity is usually inaccessible to gases. As

noted above, the internal surface area can be enhanced

by activation, i.e. mild oxidation with a gas such as

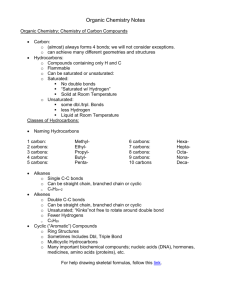

carbon dioxide, steam, or air. A volume distribution

curve for a typical activated carbon is shown in

Fig. 2.4 It can be seen that most of the internal volume

is in the form of micropores with radii of approximately 1 nm. Larger pores, classified as mesopores

and macropores, are also present, but we are not

concerned with these here. Models of the structure of

microporosity

in non-graphitising

carbons are discussed below.

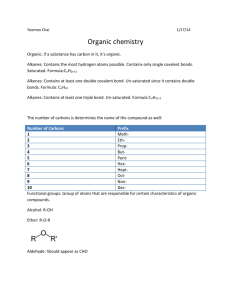

The effect of heat treatment on graphitising and

non-graphitising

carbons has been the subject of a

large number of studies. The structures of the heat

treated carbons are usually discussed in terms of the

parameters La and Lc, defined as the length and

thickness respectively of the graphite lamellae within

the carbons. In carbons prepared at temperatures

below ~ 1000°C, La and Lc in both graphitising and

non-graphitising

carbons have values around 1 nm,

indicating highly disordered structures with relatively

little graphitisation. The effect of heat treatment on

the two types of carbon differs greatly. This is illustrated in Fig. 3, taken from the work of Emmerich16

which plots La and Lc for graphitising and nongraphitising carbons heat treated at temperatures up

to 3000°C (note the La and Lc scales are logarithmic).

It can be seen that La for the graphitising carbon

reaches a value of 100 nm at 3000°C, while the

maximum value for the non-graphitising

carbon is

only 10 nm. The Lc value for the graphitising carbon

also approaches 100 nm, while for the non-graphitising carbons the maximum figure is ~4 nm. Extensive

graphite crystallites are not formed in non-graphitising carbons, even at the highest temperatures.

Other physical measurements

also demonstrate

sharp differences between graphitising and non-graphitising carbons. Table 1 (Ref. 17) shows the effect

of preparation temperature on the surface areas and

densities of a typical graphitising carbon prepared

from PVC, and a non-graphitising

carbon prepared

from cellulose. It can be seen that the graphitising

carbon prepared at 700°C has a very low surface

1.0

'I

E

c

0.8

'I

0)

ME

0.6

CJ

>1 ~~ 0.4

~.s

(J?

v.~

0

parameter on y axis gives measure of volume of gas absorbed by

pores with given radius, while x axis is log of radius r in nm

2

Differential volume distribution curve for typical

activated carbon4

International

Materials Reviews

1997

Vol. 42

NO.5

208

Harris

Structure of non-graphitising

carbons

a

100

graphltlsable

E

c:

-J1O

10

non-grophitlsable

100

graphltlsable

non-gro phltlsable

o

1000

2000

Published by Maney Publishing (c) IOM Communications Ltd

HEAT TREATMENT

3

b

3000

TEMPERATURE,

°C

Variation of La and Lc with heat treatment

temperature

for

graphitising

and

nongraphitising carbons 16

area, which changes little for carbons prepared at

higher temperatures, up to 3000°C. The density of the

carbons

increases steadily as the preparation temperature is increased, reaching a value of

2·26 g cm -3, which is the density of pure graphite, at

3000°C. The effect of preparation temperature on the

non-graphitising carbon is very different. A high

surface area is observed for the carbon prepared

at 700°C (408 m2 g -1), which falls rapidly as the

preparation temperature is increased. Despite this

reduction in surface area, however, the density of the

non-graphitising carbon is actually lower for high

preparation temperatures than it is at 700°C. This

indicates that a high proportion of 'closed porosity'

is present in the heat treated carbon.

Structure of non-graphitising

early models

carbons:

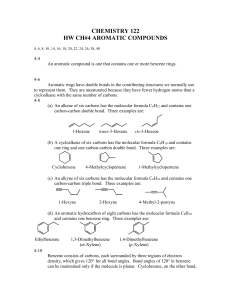

The first structural models of graphitising and nongraphitising carbons were put forward by Franklin in

her classic 1951 paper.1 In these models, the basic

units are small graphitic crystallites containing a few

layer planes, which are joined together by crosslinks.

The precise nature of the crosslinks is not specified.

A schematic illustration of Franklin's models is shown

in Fig. 4. Her theory of crystallite growth in carbons

Table 1

Starting

Effect of temperature on surface areas

and densities of carbons prepared from

PVC and cellulose 17

For carbons prepared

at

material

PVC

Cellulose

Specific surface area, m2 g-l

0-21

0-58

1-60

408

PVC

Cellulose

Helium density, g cm-3

1-85

1-90

International

2-09

1-47

Materials Reviews

0-21

1-17

0-71

2-23

0-56

2-25

2-14

2·21

1-56

2-26

1-43

1997

Vol. 42

1-70

NO.5

4

Franklin's representations of a graphitising

b non-graphitising carbons 1

and

depended on the assumption that growth results from

the movement of whole layers or large fragments

rather than individual atoms. It follows from this that

the degree of crystal growth will depend on the

orientation of the individual structural units and the

amount of crosslinking between them. In graphitising

carbons, the structural units are approximately parallel to each other, as shown in Fig. 4a, and the links

between adjacent units are assumed to be relatively

weak. On the other hand, the structural units in a

non-graphitising carbon are oriented randomly, as

shown in Fig. 4b, and the crosslinks are sufficiently

strong to impede movement of the layers into a more

parallel arrangement. Franklin's models of the structure of graphitising and non-graphitising carbons

have remained popular, and are still reproduced in

books and review articles.

The advent of high resolution electron microscopy

(HREM) in the early 1970s enabled direct images to

be recorded of the structure of non-graphitising carbons.1s Images of the freshly prepared carbons

showed a highly disordered structure, but images of

the carbons after high temperature heat treatment

were rather more informative. These apparently

showed the presence of curved and twisted graphite

sheets, typically two or three layer planes thick,

enclosing pores of the order of 5-10 nm is size. These

images led Ban et al.18 to suggest that heat treated

non-graphitising carbons have a ribbon like structure,

as shown in Fig. 5. This structure corresponds to a

Harris

Published by Maney Publishing (c) IOM Communications Ltd

5

Model of PVDC carbon heat treated

Structure of non-graphitising

carbons

209

at 1950°C, by Ban et al.18

PVDC carbon heat treated at 1950°C. These ribbon

like models are rather similar to an earlier model of

glassy carbon proposed by Jenkins and colleagues19

which is discussed further below.

The models of non-graphitising carbons described

so far have assumed that the carbon atoms are

exclusively Sp2 and are bonded in hexagonal rings.

Some authors, notably Ergun and colleagues20,21have

suggested that Sp3 bonded atoms may be present in

these carbons, basing their arguments on an analysis

of XRD patterns. The presence of diamond like

domains would be consistent with the hardness of

non-graphitising carbons, and might also explain their

extreme resistance to graphitisation.

Problems with early models

The most serious shortcoming of Franklin's models

for the structure of graphitising and non-graphitising

carbons is that the nature of the crosslinks between

the graphitic fragments is not described. Such

crosslinks must be extremely strong, since they are

sufficient to prevent graphitisation even at temperatures of 3000°C and above. The type of crosslinks

present in polymers, which are usually short linear

chains containing a few carbon atoms, would seem

to be insufficiently rigid to prevent graphitisation at

high temperatures. The idea that the crosslinks might

comprise small domains of Sp3 bonded carbons also

does not appear to stand up to detailed analysis

(see below).

Models of the kind illustrated in Fig. 5, which are

intended to represent the structure of non-graphitising

carbons following high temperature heat treatment,

also have serious weaknesses. Such models consist of

curved and twisted graphene sheets enclosing randomly shaped pores. However, graphene sheets are

known to be highly flexible, and would therefore be

expected to become ever more closely folded together

at high temperatures, in order to reduce surface

energy. Indeed, tightly folded graphene sheets are

quite frequently seen in carbons which have been

exposed to extreme conditions; examples are shown

in Fig. 6.22,23Thus, structures like the one shown in

Fig. 5 would be unlikely to be stable at very high

temperatures.

It has also been pointed out by Oberlin24 that the

early models were based on a questionable interpretation of the electron micrographs. In most micrographs of graphitised carbons, only the {0002} fringes

are resolved, and these are only visible when they

are approximately parallel to the electron beam.

Therefore, such images tend to have a ribbon like

appearance. However, since only a part of the structure is being imaged, this appearance can be misleading, and the true three-dimensional structure may be

more cage like than ribbon like. This is a very

important point, and must always be borne in mind

when analysing images of graphitic carbons.

As far as models incorporating Sp3bonded carbon

atoms are concerned, the main problem is that Sp3

bonded carbon is unstable at high temperatures.

Diamond is converted to graphite at 1700°C, as noted

above, while tetrahedrally bonded carbon atoms in

amorphous films are unstable above about 630°C.25

Therefore, the presence of Sp3 bonded atoms in a

carbon can not explain the resistance of the carbon

to graphitisation at high temperatures. The XRD

evidence for Sp3 bonded atoms in non-graphitising

carbons is also open to question. The main argument

put forward by Ergun et al.20,21 for the presence of

diamond like domains in non-graphitising carbons is

that the interference functions of such domains are

very similar to those of small graphitic structures.

Therefore, Ergun et al.20,21 argue that XRD patterns

can not be used to rule out the presence of Sp3bonded

atoms. However, a more detailed analysis of XRD

patterns from these carbons by Ruland26 suggests

that they are indeed inconsistent with a diamond like

structure. In particular, the presence of the graphite

{0002} line in patterns from non-graphitising carbons

is difficult to reconcile with a structure containing a

significant proportion of Sp3bonded atoms.

More recent models

Recently, some models of disordered carbons have

been put forward in which the carbons are not

International

Materials Reviews

1997

Vol. 42

NO.5

210

Harris

Structure of non-graphitising

carbons

-U

Published by Maney Publishing (c) IOM Communications Ltd

4nm

6

Micrographs showing tightly folded graphite sheets in carbons prepared by a arc evaporation22 and

b pyrolysis of acenaphthylene;23 c illustration of folded sheet structure

exclusively bonded in six membered rings. These

probably provide a much more realistic basis for

understanding the structure of non-graphitising

carbons than the early models based on curved and

twisted graphene sheets. In a book published in 1995,

Byrne and Marsh27 discussed the structure of carbons

produced by the pyrolysis of cellulosic type precursors. They suggested that such carbons might be

made up of small structural units such as that illustrated in Fig. 7a. This structure contains Sp2and Sp3

carbons bonded in five, six, and seven membered

rings. A group of such structures, with adsorbate

molecules situated in the gaps between the units, is

shown in Fig. 7b.

The discovery of the fullerenes has prompted several authors to put forward models of all-carbon

b

*

7

An adsorbate molecule

a Possible carbonaceous structural unit produced by pyrolysis of cellulosic precursor, according to

Byrne and Marsh;27 b model of microporous carbon made up of such units

International

Materials Reviews

1997

Vol. 42

No.5

Harris

Structure of non-graphitising

carbons

211

a

Published by Maney Publishing (c) IOM Communications Ltd

8

a Periodic negatively curved graphitic structure, from the work of Terrones et a/;31 b disordered

schwartzite structure, proposed by Townsend and co-workers32

materials

with fullerene related structures.

For

example, several groups have discussed hypothetical

'schwartzite' structures, which incorporate

negative

curvature owing to the presence of seven membered

rings.28-32 In most cases these theoretical structures

have been ordered, as in the example shown in Fig. 8a,

but disordered schwartzites have also been considered. An example of such a structure, taken from the

work of Townsend and co-workers,32 is shown in

Fig. 8b. The fragment shown contains 38 five membered rings, 394 six membered rings, 155 seven membered rings, 12 eight membered rings, and one nine

membered ring. The structure is continuous, with

no edges or unsatisfied valencies, and highly porous,

with typical pore diameters in the range 0·5-1 nm.

Townsend and co-workers determined the energy per

atom f1E of the various schwartzite structures relative

to a graphite monolayer. For the random schwartzite

they found a i1E value of 0·23 eV, considerably

lower than the value for C60 (0'42 eV), indicating

that such a structure should have high stability. They

also compared the properties of the hypothetical

schwartzite structure with those of evaporated Sp2

carbon films, and found good agreement. However,

they did not suggest that their model might be

appropriate

for microporous

carbons produced by

pyrolysis.

Evidence for fullerene like structures in

non-graphitising carbons

Recently, the present author and colleagues have

carried out a study of the effect of high temperature

heat treatment on non-graphitising

carbons using

HREM.15 It was shown that such heat treatments

can result in the formation of closed carbon nanoparticles, which are apparently fullerene like in structure.

This suggested that fullerene like elements were present in the original carbons, and prompted us to

propose a new model for non-graphitising

carbons.

Before describing this model, a brief summary will be

given of the HREM observations.

Two carbons were studied, prepared by the pyrolysis of a PVDC polymer and of sucrose, which were

two of the precursors used by Franklin in her classic

work. Pyrolysis was carried out under nitrogen at

about 700°C, producing carbons which were highly

disordered. Figure 9a shows a micrograph

of the

freshly prepared sucrose carbon. The microstructure

apparently consists of tightly curled single carbon

layers, although high resolution images of such noncrystalline materials are difficult to interpret directly.

Following heat treatment at 2600°C, however, many

regions of the carbon appear to consist largely of

closed nanoparticles,

as shown in Fig. 9b. Higher

magnification images in which individual nanoparticles can be more clearly seen are shown in Fig. 10.15

Sometimes, much smaller closed structures with diameters of the order of 1 nm or less could be found;

examples are shown in Fig. 11. These structures are

similar in size to small fullerenes like C60 and C70.

However, attempts to extract C60 and other fullerene

molecules from the heat treated carbons have so far

been unsuccessful.

It should be pointed out that there were many

regions in the heat treated samples in which the

transformation into nanoparticles was not as obvious

as it is in Figs. 9b and 10. Many regions were too

thick to enable individual nanoparticles to be seen,

and the nanoparticles were often partially obscured

by disordered material. This probably explains why

closed structures such as those shown here have not

been clearly identified before.

It seems very likely that particles such as those

shown in Figs. 9b and 10 contain pentagonal carbon

rings, as in fullerenes, since it is difficult to envisage

any other explanation

for their closed structures.

Indeed, the nanoparticles shown here are rather similar to particles which can be produced by arc evaporation in a fullerene generator,13,14 although in the

latter case the particles usually contain many more

layers. As in the case of fullerenes, 12 pentagons must

be present in each shell of the nanoparticles in order

to produce closure. Although the shapes of the

International

Materials Reviews

1997

Vol. 42

NO.5

Harris

Structure of non-graphitising

carbons

Published by Maney Publishing (c) IOM Communications Ltd

212

10

9

a Micrograph

of freshly prepared sucrose

carbon; b same carbon following heat treatment

at 2600°C; scale bar 5 nm

nanoparticles shown here are less symmetrical

than in small fullerenes such as C60, this does not

argue against a fullerene related structure, since giant

fullerenes can have a variety of different shapes, as

illustrated in Fig. 12. Features such as the saddle

points shown in Fig. lOb are evidence for the

presence of seven membered rings as well as pentagons in the heat treated carbons. The existence of

large numbers of fullerene like nanoparticles in the

heat treated carbons explains the observation of

'closed porosity' in such materials, as discussed in

previous sections. The nanoparticles constitute completely sealed capsules which would be impermeable

to any gas. Alternative models, such as that proposed

International

Materials Reviews

1997

Vol. 42

NO.5

a Micrograph

showing closed structure in

PVDC derived

carbon

heated at 2600°C;

b another micrograph of same sample with

arrows showing regions of negative curvature;

scale bar 5 nm (Ref. 15)

by Byrne and Marsh27 and illustrated in Fig. 7, do

not seem to be capable of explaining the observed

closed porosity.

New model for structure of non-graphitising

carbons

The observations described in the previous section

suggest that non-graphitising carbons may have

fullerene like microstructures. One possible model

for these materials, therefore, might be the 'random

schwartzite' structure discussed above. However there

are aspects of this model which do not seem appropriate for non-graphitising carbons. In particular, the

Harris

Structure of non-graphitising

carbons

213

Published by Maney Publishing (c) IOM Communications Ltd

our model we envisage a higher proportion of pentagons and a smaller proportion of heptagons than in

the random schwartzite structure. This is supported

by the observation that the materials can be converted

by heat treatment to closed carbon nanoparticles,

each containing 12 pentagonal rings, suggesting that

a large number of such rings may have been present

in the original carbon. The size of the micropores in

our model, as well as in the random schwartzite

structure, is of the order 0·5-1 nm, which is similar

to the pore sizes observed in typical microporous

carbons, as noted above.

If the model we are proposing for non-graphitising

carbons is correct, it suggests that these carbons are

very similar in structure to fullerene soot, the low

density, disordered material which forms on the walls

of the arc evaporation vessel and from which C60 and

other fullerenes may be extracted. Fullerene soot is

known to be microporous, with a surface area, after

activation with carbon dioxide, of ",700 m2 g-1,33

and detailed analysis of high resolution electron

micrographs of fullerene soot has shown that these

are consistent with a random schwartzite type structure.34 It is significant that high temperature heat

treatments can transform fullerene soot into nanoparticles very similar to those observed in heated

microporous carbon.35

Finally in this section, it is worth making a few

comments on the 'activation' process which is essential for developing a very high surface area in nongraphitising

carbons. Activation

usually involves

treatment with a mild oxidising agent, such as CO2

or water vapour, and it is generally believed that this

has the effect of burning away carbon fragments

inside micropores,

thus enhancing surface area.27

However, if our new model for the structure of

microporous carbons is correct, then this activation

treatment may also have a further consequence. It is

known that mild oxidation, for example with CO2 at

850°C, can remove the caps from carbon nanotubes

by selectively attacking the pentagonal carbon rings.36

If microporous carbons have a fullerene like structure,

then the effect of such a treatment would be to open

closed pores by selective attack of the pentagons, thus

increasing the surface area significantly.

Glassy carbon

11

Micrographs

showing

very small

closed

structures in sucrose carbon heat treated at

2600°C; scale bar 2 nm

random schwartzite structure consists of a single

continuous sheet, while non-graphitising

carbons are

believed to be made up of relatively small fragments.24

An unbroken sheet such as that illustrated in Fig. 8b,

with no edges or dangling bonds, would have a very

low reactivity, unlike most non-graphitising

carbons

which can be quite readily oxidised at moderate

temperatures. The present author and S. C. Tsang

have therefore proposed a modeP5 for the structure

of non-graphitising carbons which consists of discrete

fragments of randomly curved carbon sheets, rather

than an unbroken sheet, as illustrated in Fig. 13. In

The so called glassy carbons are produced by the slow

pyrolysis of certain polymers at temperatures in the

range 900-1 aao°c. The resulting carbons are hard,

low density materials which can not be graphitised,

but unlike most non-graphitising

carbons they are

impermeable to gases. Perhaps their most remarkable

property is their chemical inertness. It has been demonstrated that the rates of oxidation of glassy carbon in

oxygen, carbon dioxide, or water vapour are lower

than those of any other carbon. They are also highly

resistant to attack by acids. Thus, while normal graphite is reduced to a powder by a mixture of concentrated

sulphuric and nitric acids at room temperature, glassy

carbon is unaffected by such treatment, even after

several months.37 This property makes glassy carbon

a useful material for crucibles. It is also used widely

as an electrode material in electrochemistry.

International

Materials Reviews

1997

Vol. 42

No.5

214

Harris

a

C'500

(Ih

Structure of non-graphitising

symmetry); b

C600

(D2h symmetry); c

carbons

C660

(tetrahedral symmetry)

Published by Maney Publishing (c) IOM Communications Ltd

12 Giant fullerene structures with various symmetries, each containing

Some of the earliest structural models for glassy

carbon assumed that both Sp2and Sp3bonded atoms

were present. 38Graphitic domains were envisaged to

be interspersed with tetrahedral domains, perhaps

linked by short oxygen containing bridges. These

models were based primarily on an analysis of

XRD measurements and, as mentioned above, such

measurements can be open to a number of interpretations. It should also be noted that neutron diffraction

data have shown an absence of tetrahedrally bonded

domains in glassy carbon heat treated at 2000°C,39

A different model for the structure of glassy carbon

was put forward by Jenkins and Kawamura19 in 1972.

This model, illustrated in Fig. 14, is based on the

assumption that the molecular orientation of the

polymeric precursor material is memorised to some

extent after carbonisation. Thus, the structure bears

some resemblance to that of a polymer, in which the

'fibrils' are very narrow curved and twisted ribbons

of graphitic carbon. The Jenkins-Kawamura model

has been quite widely accepted, but appears to be

deficient in a number of aspects. For example, a

structure such as that shown in Fig. 14, with many

conjoined micropores, would be expected to be per-

12 pentagonal rings30

meable to gases, whereas we know that glassy carbons

are highly impermeable. The structure also has a high

proportion of edge atoms, which are known to have

a relatively high reactivity compared with 'in plane'

carbon atoms.

An alternative model for glassy carbon would be

one in which the basic structural units are fullerenelike closed particles, as shown in Fig. 15. Such a

structure would be impermeable and have a much

lower reactivity than the Jenkins-Kawamura structure. In the schematic illustration shown in Fig. 15,

the individual particles are of the order of 1 nm in

size. This is consistent with high resolution electron

micrographs of glassy carbon, which show little evidence of any structure, suggesting the basic structural

units are extremely small.

A model of heat treated glassy carbon which also

involves cage like components was proposed by

Japanese workers in 1984.40,41This is illustrated in

Fig. 16. Here, the particles are multilayered and have

inner cavities ~ 50 nm dia. This model was put forward before the discovery of C60, and the possibility

that the closed particles might contain non-six membered rings was not considered.

Carbon fibres

13

Schematic illustration of model for structure

of non-graphitising carbons based on fullerene

like elements 15

International

Materials Reviews

1997

Vol. 42

NO.5

Most commercial carbon fibres are produced either

from polyacrylonitrile (PAN) or from mesophase

pitch.42 Fibres derived from pitch are highly graphitic,

and have high elastic moduli, while those derived

from PAN have a much more imperfect, lower density

structure. The lack of extended structure in PAN

derived fibres makes them relatively insensitive to

flaws, giving them higher strength but lower modulus

than pitch derived fibres. The properties of PAN

derived fibres result from the fact that PAN is nongraphitising, and a brief discussion of their structure

is therefore appropriate here.

XRD of PAN derived fibres produces La values of

approximately 4-10 nm depending on the annealing

temperature.43 HREM shows that the fibres have an

imperfect structure, containing many elongated voids.

Several models have been put forward for the structure of PAN derived carbon fibres, all based on the

assumption that the basic structural units are graphite

Harris

Structure of non-graphitising

carbons

215

!

Lc

Published by Maney Publishing (c) IOM Communications Ltd

1

14 Model by Jenkins and Kawamura for structure of glassy carbon 19

sheets or ribbons. A model suggested by Crawford

and Johnson44 is shown in Fig. 17. Here, the structure

consists of a random arrangement of flat or crumpled

graphite sheets, with all the a-b planes running parallel to the fibre axis. However, given the flexibility of

graphite sheets, illustrated in Fig. 6, it is difficult to see

how the voids in such a structure could survive high

temperature heat treatment. Therefore, the possibility

that the voids in fact result from the presence of

fullerene like elements is worthy of consideration. The

elongated shapes of the voids suggests that they may

have structures related to those of carbon nanotubes.

Soot and carbon black

products.45 The possibility that soot particles might

be fullerene like was first suggested by Smalley and

co-workers in 1986,46 and discussed further by Kroto

and McKay in 1988.47 In these papers it was proposed

that the soot particles grew by a mechanism related

to the so called 'pentagon road' model, which involves

the incorporation of pentagonal rings into a growing

carbon network, driven by the need to eliminate

dangling bonds. If the pentagons occur in the 'correct'

positions then C60 and other fullerenes will result but,

in general, closed structures will not be formed and

the growing shell will then tend to curl around on

itself like a nautilus shell. However, this model was

not greeted favourably by soot experts,48 who argued

Soot is another carbon material whose structure is

poorly understood. It usually consists of quasi spherical particles ranging from about 10 to about 500 nm

in size, which are often joined together in clusters or

'necklace' chains. Carbon black is essentially a very

pure form of soot, which is of great commercial

importance as a pigment and as a filler in rubber

15 nm I

15

Model

for

structure

of

glassy

carbon

containing closed, fullerene like particles

16 Model for structure of glassy carbon derived

from phenol resin following heat treatment at

2800°C (Refs. 40, 41)

International

Materials Reviews

1997

Vol. 42

NO.5

Published by Maney Publishing (c) IOM Communications Ltd

216

17

Harris

Structure of non-graphitising

carbons

Model suggested by Crawford and Johnson for structure of PAN derived carbon fibres44

that it was inconsistent with both the kinetics of soot

formation and the structural characteristics of the

particles. Concerning kinetics, it was pointed out that

the growth of curved shell structures would be much

slower than those of planar fragments. Soot formation

is known to be extremely rapid, so it seemed unlikely

that the growth of fullerene like shells could be

involved. Their structural arguments were based on

XRD and 13C NMR patterns of combustion soot,

which they suggested were inconsistent with the icospiral model. They pointed out that d spacings for

continuously curving icospirals would be lower than

those observed experimentally in XRD studies of

soot, while 13CNMR spectra of soot resemble those

of aromatic molecules much more closely than those

of fullerenes. However, evidence from XRD and 13e

NMR of soot particles is difficult to interpret when

one is dealing with disordered materials such as

carbon blacks, and can not be said to provide definitive proof of the structure.

Since structural measurements on the soot particles

themselves is difficult, it is worth considering whether

any insights into their structure can be gained from

the way in which the particles are transformed by

high temperature heat treatment. It is well established

that such treatments transform carbon black particles

into faceted particles which sometimes appear to have

closed shell like structures. The precise structure of

the graphitised particles depends on the nature of the

original carbon black. In some cases, relatively large,

discrete particles are formed, as shown in Fig. 18a,

taken from the work of Graham and Kay.49 Other

graphitised carbon blacks have a less well defined

structure as in Fig. 18b, from the work of Marsh and

co-workers, 50 with many bent and faceted layer planes

and some apparently closed shell structures. The

presence of sharply bent planes and closed particles

International

Materials Reviews

1997

Vol. 42

NO.5

is indicative of the presence of pentagonal rings, and

suggests that fullerene like elements may have been

present in the original carbon black and soot particles.

Further detailed work on the graphitisation of carbon

blacks might help to confirm this.

Discussion

The discovery of the fullerenes has prompted a

number of workers to speculate that fullerene like

elements, i.e. curved structures containing non-six

membered rings, may be present in well known forms

of carbon.46,47,51To date, most of this speculation

has centred on spheroidal structures such as soot and

carbon black particles. However, as discussed in the

present paper, there are good reasons to believe that

fullerene related structures may be present in other

well known carbon materials such as microporous,

non-graphitising carbon, glassy carbon, and carbon

fibres. If correct, this idea would help in explaining

the properties of these carbons. Most importantly,

the presence of fullerene like elements could explain

why certain carbons can not be transformed into

graphite by high temperature heat treatment, a problem which has not been fully understood since the

1951 work of Rosalind Franklin.

One of the main reasons for believing that nongraphitising carbons may be fullerene like, is that

they can be transformed by high temperature heat

treatment into structures containing many closed

carbon cages. Of course, it could be argued that the

pentagonal rings form during the high temperature

heat treatment, and are not present in the original

carbon. However, this raises the question of why

pentagons are not formed during the heat treatment

of graphitising carbons such as PVC derived carbon

and petroleum coke. The presence of non-six

Harris

Structure of non-graphitising

carbons

217

Published by Maney Publishing (c) IOM Communications Ltd

The nature of the transformation from microporous

non-graphitising

carbon to a structure containing

closed carbon cages is not well understood,

and

further work on this problem would be welcome. The

mechanism may involve ring migration mechanisms

such as the Stone-Wales rearrangement, 52 which has

been invoked to explain fullerene isomerisation. It is

notable that the cage structures observed in heat

treated non-graphitising

carbons fall into quite a

narrow size range, typically 5-15 nm, suggesting that

structures in this size range have a special stability.

Recent work has demonstrated that crystalline C60 is

also transformed into nanoparticles in this size range

by high temperature heat treatments. 53

There are other aspects of non-graphitising carbons

which remain inadequately understood. In particular,

there is the very basic question of why some organic

materials produce graphitising carbons and others

yield non-graphitising

carbons. If the ideas put forward in this review are correct, this question becomes:

why do some precursors form five membered rings

when carbonised, and others only hexagonal? There

is unlikely to be a simple answer to this question,

since the carbonisation

of organic materials is an

immensely complex process, and there is rarely a

simple relationship between the structure of the original precursor and the nature of the carbon produced

by pyrolysis. For example, structures which contain

five membered rings can produce either graphitising

or non-graphitising

carbon.54 In fact, it is generally

believed that the physical properties of the precursors,

and the conditions under which pyrolysis is carried

out, are more important than chemical structure in

determining whether the final carbon is graphitising

or non-graphitising.

Thus, graphitising carbons usually form a liquid on heating to temperatures around

400-500°C, while non-graphitising

carbons generally

form solid chars without melting. The liquid phase

produced on heating graphitising carbons is believed

to provide the mobility necessary to form oriented

regions. However, this may not be a complete explanation, since some precursors, such as sucrose, form

non-graphitising

carbons despite passing through a

liquid phase. There is clearly a need for more work

in this area, and on many other aspects of nongraphitising carbon, in the light of the new knowledge

we have gained about carbon since the discovery of

the fullerenes.

Acknowledgement

The author thanks Dr S. C. Tsang for discussions.

References

1.

18

a Faceted particles in graphitised carbon black

sample,49 scale bar 100 nm; b graphitised

carbon black containing bent and faceted layer

planes, and some closed particles,5o scale bar

10nm

Proc. R. Soc. (London)

A, 1951, A209, 196-

218.

2.

3.

4.

5.

membered rings in non-graphitising

carbons also

explains many of their physical properties such as

microporosity and hardness.

R. E. FRANKLIN:

6.

7.

Carbon, 1988, 26, 267-274.

(ed.): 'Introduction to carbon science'; 1989, London,

Butterworths.

H. JANKOWSKA,

A. SWIATKOWSKI,

and J. CHOMA: 'Active carbon';

1991, New York, NY, Ellis Horwood.

J. W. PATRICK (ed.): 'Porosity in carbons: characterisation and

applications'; 1995, London, Arnold.

H. C. FOLEY: Microporous

Mater., 1995, 4, 407-433.

H. W. KROTO,

J. R. HEATH,

S. C. O'BRIEN,

R. F. CURL,

and

R. E. SMALLEY: Nature, 1985, 318, 162-163.

B. McENANEY:

H. MARSH

International

Materials Reviews

1997

Vol. 42

NO.5

218

8.

W.

Harris

Structure of non-graphitising

KRATSCHMER,

D. R. HUFFMAN:

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

Published by Maney Publishing (c) IOM Communications Ltd

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

L.

D.

LAMB,

K.

carbons

FOSTIROPOULOS,

and

Nature, 1990, 347, 354-358.

s. DRESSELHAUS, G. DRESSELHAUS, and P. C. EKLUND: 'Science

of fullerenes and carbon nanotubes'; 1996, San Diego, CA,

Academic Press.

s. IIJIMA: Nature, 1991, 354, 56-58.

T. W. EBBESEN and P. M. AJAYAN: Nature, 1992,358, 220-222.

T. W. EBBESEN (ed.): 'Carbon nanotubes: preparation and properties'; 1997, Boca Raton, FL, CRC Press.

P. J. F. HARRIS, M. L. H. GREEN, _and s. C. TSANG: J. Chern. Soc.,

Faraday Trans., 1993, 89, 1189-1192.

Y. SAITO, T. YOSHIKAWA, M. INAGAKI, M. TOMITA, and T. HAYASHI:

Chern. Phys. Lett., 1993, 204, 277-282.

P. J. F. HARRIS and s. c. TSANG: Philos. Mag. A, 1997,76,667-677.

F. G. EMMERICH:

Carbon, 1995, 33, 1709-1715.

1.

J.

KIPLING,

J.

N.

SHERWOOD,

P.

V.

SHOOTER,

and

N. R. THOMPSON:

Carbon, 1964, 1, 321-328.

L. L. BAN, D. CRAWFORD,

and H. MARSH: J. Appl. Crystallogr.,

1975, 8, 415-420.

G. M. JENKINS,

K. KAWAMURA,

and L. L. BAN: Proc. R. Soc.

(London) A, 1972, A327, 501-517.

S. ERGUN and v. H. TIENSUU: Acta Crystallogr.,

1959, 12, 10501051.

S. ERGUN and L. E. ALEXANDER:

Nature, 1962, 195, 765-767.

D. UGARTE: Chern. Phys. Lett., 1992, 198, 596-602.

P. R. BUSECK, H. BO-JUN,

and L. P. KELLER: Energy Fuels, 1987,

1, 105-110.

A. OBERLIN: Chern. Phys. Carbon, 1989, 22, 1-143.

D. R. McKENZIE: Rep. Prog. Phys., 1996, 59, 1611-1664.

W. RULAND:

Chern. Phys. Carbon, 1968,4, 1-84.

1. F. BYRNE and H. MARSH: in 'Porosity in carbons: characterisation and applications', (ed. J. W. Patrick), 1-48; 1995,

London, Arnold.

A. L. MACKAY and H. TERRONES: Nature, 1991,352, 762.

T. LENOSKY, X. GONZE,

M. TETER, and v. ELSER: Nature,

1992,

355, 333-335.

H. TERRONES and M. TERRONES: J. Phys. Chern. Solids, 1997, 58,

1789-1796.

H. TERRONES,

M. TERRONES,

and w. K. HSU: Chern. Soc. Rev.,

1995, 24, 341-350.

M.

International

Materials Reviews

1997

Vol. 42

NO.5

32. s. J. TOWNSEND, T. J. LEKOSKY, D. A. MULLER, C. S. NICHOLS, and

v. ELSER: Phys. Rev. Lett., 1992, 69, 921-924.

33. s. C. TSANG, P. J. F. HARRIS, J. B. CLARIDGE, and M. L. H. GREEN:

J. Chern. Soc., Chern. Cornrn., 1993, 1519-1522.

34. L. A. BURSILL and L. N. BOURGEOIS: Mod. Phys. Lett., 1995, B9,

1461-1470.

35. w. A. DE HEER and D. UGARTE: Chern. Phys. Lett., 1993,

207, 480-486.

36. s. C. TSANG, P. J. F. HARRIS, and M. L. H. GREEN: Nature, 1993,

362, 520-522.

37. S. YAMADA, H. SATO, and T. ISHII: Carbon, 1964, 2, 253-260.

38. J. KAKI:"lOKI: Acta Crystallogr., 1965, 18, 578.

39. D. F. R. MILDNER and J. M. CARPENTER: J. Non-Cryst. Solids,

1982,47,391-402.

40. M. SHIRAISHI: 'Introduction to carbon materials'; 1984, Tokyo,

Carbon Society of Japan (in Japanese).

41. A. YOSHIDA, Y. KABURAGI, and Y. HISHIYAMA: Carbon, 1991, 29,

1107-1111.

42. M. S. DRESSELHAUS, G. DRESSELHAUS, K. SUGIHARA, I. L. SPAIN,

and H. A. GOLDBERG: 'Graphite fibers and filaments'; 1988,

Berlin, Springer-Verlag.

43. D. 1. JOHNSON: Philos. Trans. R. Soc. (London) A, 1980, A294,

443-449.

44. D. CRAWFORD and D. J. JOHNSON: J. Microsc., 1971,94, 51-62.

45. 1.-B. DONNET, R. C. BANSAL, and 1. WANG: 'Carbon black', 2nd

edn; 1993, New York, NY, Marcel Dekker.

46. Q. L. ZHANG, S. C. O'BRIEN, J. R. HEATH, Y. LIU, R. F. CURL,

H. W. KROTO,

and R. E. SMALLEY: J. Phys. Chern., 1986, 90,

525-528.

47. H. W. KROTO and K. McKAY: Nature, 1988, 331, 328-331.

48. L. B. EBERT: Carbon, 1993, 31, 239-240.

49. D. GRAHAM and w. s. KAY: J. Colloid Sci., 1961, 16, 182-185.

50. P. A. MARSH, A. VOET, T. 1. MULLINS, and L. D. PRICE: Carbon,

1971, 9, 797-805.

51. H. w. KROTO: Science, 1988, 242, 1139-1145.

52. A. J. STONE and D. J. WALES: Chern. Phys. Lett., 1986, 128,

501-503.

53. I. MOCHIDA, M. EGASHIRA, Y. KORAl, and K. YOKOGAWA: Carbon,

1997,35,1707-1712.

54. I. C. LEWIS: Carbon, 1982, 20, 519-529.