small-scale systems for solar-thermal desalination of sea and

advertisement

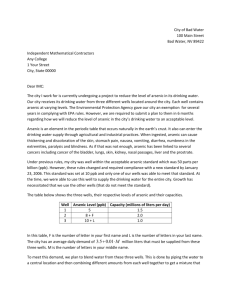

SMALL-SCALE SYSTEMS FOR SOLAR-THERMAL DESALINATION OF SEA AND BRACKISH WATER Markus Spinnler, Jürgen Blumenberg, Wolfgang Moik, Hendrik Müller-Holst, Hans-Ulrich Krispler, EUVT, Technical University of Munich1 EUVT, Technical University of Munich Moik Industrial Components2 Division 4: Solar Thermal and Biomass, ZAE Bayern3 CASE GmbH4 ABSTRACT Clean drinking water is one of the most important international health issues today: In many places of the world, only brackish or polluted water is available. In W EST BENGAL and BANGLADESH, villagers have been severely afflicted by drinking water from deep wells containing arsenic. This fact leads to an increasing interest in new water purification technologies (desalination technologies respectively). The standard methods are reliable in the fresh water capacity range of some 100 to 200.000 m3 per day. They are not used in decentralized regions due to their permanent need of qualified maintenance, infrastructure and high costs. Here, the use of smallscale solar desalination systems is desirable and makes economic sense. For this purpose, two systems were developed in Munich: (1) Together with CASE GmbH, MUNICH, and the Austrian company MOIK, HALLEIN, the TECHNICAL UNIVERSITY OF MUNICH developed the AQUASOL single-stage-flash-evaporation unit. (2) The GOR multi-effect humidification unit has been developed and optimized by the ZAE BAYERN and T.A.S. GmbH. The investigated water purification plants are described in detail, operation principles, energy consumption ratios, amount of maintenance and financial aspects are compared and summarized. Both working groups started a cooperation to solve the problems in removing arsenic from contaminated well water. Experiments on this topic showing satisfactory results are presented and a possible benefit for the people of W EST BENGAL and BANGLADESH is discussed. 1 TU MÜNCHEN, LTD, Boltzmannstr. 15, D-85747 Garching, Germany, Tel.: + 49 – 89 – 289 – 16223 W OLFGANG MOIK INDUSTRIEPRODUKTE, Untersbergweg 14, A-5400 Hallein, Austria, Tel.: + 43 – 6245 – 7617 – 4 3 ZAE BAYERN, ABTEILUNG 4, Domagkstraße 11, D-80807 München, Germany, Tel.: + 49 – 89 – 35 62 50 – 17 4 CASE GMBH, Westendstraße 125, D-80339 München, Germany, Tel.: + 49 – 89 – 50 03 59 – 0 2 OVERVIEW ON DESALINATION PROCESSES Mostly applied desalination processes are the Multi-Stage-Flash (MSF), the MultieffectDistillation (ME) with Thermal Vapor Compression (ME-TVC) or with Mechanical Vapor Compression (ME-MVC) and the reverse Osmosis Method (RO). By coupling them with solar collectors, distillation, MSF and ME-plants can be driven by solar energy. Their specific energy consumption varies between 40 and 70 kWh/m3distillate thermal and up to 4 kWh/m3distillate electrical energy. The choice of any process depends on the salt concentration as well as on the process economics. As main problems, high investment costs as well as an high amount of maintenance in these hightech plants can be mentioned. [1][2] In the following, two small scale systems for thermal desalination of sea and brackish water are described in detail. A major skill of the two plants is their extremely low need of maintenance and their ability of autonomous decentralized stand-alone operation. THE AQUASOL FLASH-EVAPORATION PLANT The AQUASOL-project was realized by the companies CASE GmbH AND MOIK INDUSTRIAL COMPONENTS in close cooperation with the TECHNICAL UNIVERSITY OF MUNICH (TUM), where optimization and testing is carried out. It was planned to develop a low-cost solar desalination plant for decentralized use with a daily fresh water output of 100 l for application in remote areas with lack of clear water. It should be possible to build up and maintain the plant easily on site. Application possibilities are the desalination of brackish or sea water. Main goal is the supply of families and small farms in remote areas. The daily production should be enough to cover their fresh water demand. Basic idea of the AQUASOL unit is the use of a single flash stage at ambient pressure. Further measures aim at enhancing the air humidification rate. The AQUASOL project was realized in three steps, including a feasibility study for the process in 1996, investigation of a laboratory-scale pilot plant in 1997 and a prototype on the solar experimentation field of TUM in 1998. For developing pilot plant and prototype, a numerical simulation program was developed. Extensive experimental investigations for testing the plants and for validating the simulation program were carried out. Seawater Desalination by flash evaporation Figure 1 shows the operation principle of the AQUASOL desalination plant. The AQUASOL plant is consisting of two parts: a pressurized section and an ambient pressure section. The pressurized section of the plant is fed by a sea-water pump, which brings feed water to a required total pressure of 2 bars in order to avoid boiling while temperatures exceed 100°C. In the following, feed water is preheated by two heat exchangers, brine heat exchanger and condenser, respectively. In a final step, feed water is heated up to 120°C by the solar collector system. Passing through an expansion valve, the overheated water now flashes to the ambient pressure section, where two physical effects support evaporation: flash evaporation as well as air humidification. The two phases (1) steam with saturated air and (2) brine pass the separator, where steam and saturated air are condensed by flowing in contact with the condenser and the brine is fed back for preheating the feed water. The pressurized section of the two pilot plants was realized with an excenter pump and a pipe-assembly heat exchanger as condenser which was built in stainless steel 1.4539. In the pilot plant, the feed water was heated up to a temperature of 120°C by means of an adjustable electrical heating system (total power: 18 kW), which was used for simulating different thermal loads. Flash temperature is kept constant by varying the feed flow via the speed of pump. Figure 1: Principle of the AQUASOL -Process Due to the high material and manufacturing costs of sea-water resistant heat exchangers, the brine heat exchanger was replaced by a mixing basin, where 50% of the heated brine are remixed and thus preheat the feed water. Expansion of heated sea or brackish water is realized by special PTFE pressure relief valves of 2 bar tripping pressure. In the flash chamber, made of ceramic-coated steel, a dashboard is separating the steam from the liquid brine. The steam is rising to the condenser, whereas the brine is collected in the brine chamber. Piping and containers in the ambient pressure section are made of polymers. A schematic view of the laboratory plant can be seen in figure 2. In 1998, experiences with the pilot plant were transferred to a prototype working with 6 m2 vacuum-tube solar collectors (STIEBEL ELTRON SOL 200 A), which were installed on a 1-axis tracking device for seasonal tracking and were equipped with specially developed sea-water resistant heat collector heads. As back-up, an additional electrical heating system was installed. Furthermore, thermal insulation of both flash chamber and piping was improved. Figure 3 shows a photo of the prototype. Three collector modules with 2 m2 absorber area each can be seen as well as the flash chamber and the excenter pump at the left hand side. Fig. 2: AQUASOL Pilot Plant Fig. 3: AQUASOL prototype at TUM Experiments On both plants, steady state experiments were carried out in order to achieve comparable results for distillate output as a function of thermal input and flash temperature. Besides, day simulations were carried out for getting information about the possible daily distillate output. As a reference for day simulations, the 1st July at ALMERÍA (ANDALUCÍA, SPAIN) was fixed together with a vacuum-tube collector area of 6 m2 (STIEBEL ELTRON SOL 200 A). Figure 4 shows the results for steady state experiments. Efficiency is rising together with higher solar irradiation and flash temperature. The specific thermal energy consumption reaches approximately 1 kWh/ldistillate at high irradiation values of 1.000 W/m2. Testing the prototype, distillate output could be increased by 10%. Together with the new stainless heat collectors, a total collector efficiency of 50% could be measured, what indicates a satisfying operation of the modified collector system. Day simulations at ALMERÍA yield a daily production of 30 to 40 l/d. Furthermore, theoretical results of numerical process simulation go in conformity with experimental data. Small deviations between theory and experiment are caused by steam and heat losses, which are not being considered in the simulation. [2][3] Fig. 4: Distillation output at steady-state Results and Conclusion During research on the AQUASOL project, feasibility of the process was demonstrated, a pilot plant and an improved prototype were working successfully. A main problem of the AQUASOL desalination process is its high energy consumption which could be lowered by improving air humidification processes in the flash chamber itself. Other crucial problems are the relatively complicated control mechanism and the need to use sea water resistant steel qualities. The price of the plant has been fixed at 10.000 US$, where the majority of the costs result in using vacuum tube collectors. Based on the technical protocols for solar collectors of TECHNIKUM RAPPERSWIL [4], economic alternatives to these high-tech collectors have been developed and several commercial flat plate collectors are taken under consideration. An experimental validation in Munich is planned. Another project aims at developing a low-tech sea-water resistant parabolic through collector for temperatures of 120°C. A simulation program for collector design has been developed, the erection of first test collectors is planned for summer 2000. THE GOR MULTIEFFECT HUMIDIFICATION PLANT The GOR multi-effect humidification unit has been developed and optimized by ZAE BAYERN and T.A.S. GmbH. It can be driven by low-grade thermal energy, either by use of solar thermal energy, by wind or by supply of waste heat from generating sets or industrial plants. The thermodynamic principle of multi effect humidification is based on the evaporation and condensation of water inside a thermally insulated box at ambient pressure. Vapor is transported from the evaporator to the condenser, where the distilled water is collected. The process has been technically optimized, so that the air circulation is driven entirely by natural convection and high heat recovery ratios can be realized. The GOR desalination system is also sized for small groups or villages with a drinking water demand of up to several 1000 l/d. A pilot system has been installed in FUERTEVENTURA (CANARY ISLANDS, SPAIN) and has been measured and analyzed in detail by the ZAE BAYERN since 1992. In 1997, a desalination system with 24 hour thermal storage system was erected in SFAX, TUNISIA. Seawater Desalination by Multieffect Humidification The principle of this desalination process is based on the evaporation of water and the condensation of steam to and from humid air, that flows in a circuit driven by natural convection between condenser and evaporator (clockwise in figure 5). Evaporator and condenser are located in the same thermally insulated box. In the evaporator, hot seawater is distributed onto vertically hanging fleeces made of polypropylene and is slowly trickling downwards. The air moves in countercurrent flow to the brine through the evaporator and becomes saturated with humidity. Partial evaporation cools the brine which leaves the evaporation unit at higher salt concentration and a temperature of approximately 45°C. The condenser unit is located opposite to the evaporator. Here, the saturated air condenses on a flat plate heat exchanger made of polypropylene. The distillate is flowing down the plates and is trickling into a collecting basin. The heat of condensation is mainly transferred to the cold sea water flowing upwards inside the flat plate heat exchanger. Thus, brine temperature in the condenser rises from 40°C to approximately 75°C. In the next step, the brine is heated up to the evaporator inlet temperature, which is between 80°C to 90°C by one of the heat sources mentioned above. In order to make the process competitive from economic point of view, 24 hours operation of the desalination system is indispensable. Thus, if the system is driven solarthermally, a thermal storage tank has to be implemented. The outstanding advantage of the natural air convection loop inside the distillation unit is the fact that it is self-adjusting to the optimum operating state regarding to the preset parameters. By changing these parameters – evaporator inlet temperature and load volume flow – it is possible to influence and optimize the thermal efficiency of the system for a determined solar input. A TRNSYS transient simulation tool for the distillation unit as well as simulation tools for collector field and thermal storage have been developed by ZAE BAYERN. [5] Experimental Investigation The following considerations are based on actual laboratory investigations at ZAE BAYERN. Here, a distillation module similar to the demonstration plant in FUERTEVENTURA, is installed. Steady state operation modes with various load parameters have been investigated. The evaporator inlet temperature, the condenser inlet temperature and the volume flow of the brine were varied. As can be seen in figure 6, an increasing evaporator inlet temperature at constant brine load flow causes rising distillate volume flow, because the evaporation and condensation process is much more efficient at high temperatures. It is obvious, that a higher distillate flow can be achieved with increasing load flow, even when limited at flow rates higher than 600 l/h due to overstraining the evaporation and condensation surfaces. The energetic process efficiency also strongly depends on the load flow of the system. Higher load flow and distillate production need higher temperature differences for constant transfer resistances. Hence, the heating demand rises. The temperature dependence of the specific energy consumption is inverse proportional due to an improvement of heat and mass transfer at higher temperatures. [5][6] Figure 6 shows also, that the specific energy consumption of the process can reach about 100 kWh/m3distillate, what is one order of magnitude lower than at AQUASOL. The estimated distillate costs which can be achieved with a load flow of 600 l/h at an evaporator inlet temperature of 85°C are 20 US$/m3 using solar collectors as heat source. [5] Figure 5: Principle of the GOR-Process Figure 6: Specific energy demand for different operation modes at 40°C condenser inlet temperature ARSENIC CALAMITY IN BANGLADESH AND WEST BENGAL In W EST BENGAL and BANGLADESH, tube-well groundwater has been found to be contaminated with arsenic, which occurs naturally in alluvial and deltaic sediments. It is containing high arsenic levels, in some places several hundred times the level recommended by the W ORLD HEALTH ORGANIZATION WHO for acceptable drinking water. The latest statistics available on the arsenic contamination in groundwater indicates that around 85% of the total area of Bangladesh and about 75 million people are at risk of severe health problems. It is estimated that at least 1.2 million people are exposed to arsenic poisoning with 24 millions potentially exposed. [7] The introduction of deep-drilled tube wells some decades ago not only supplied farmers with irrigation water throughout the dry season but also provided families and villages with a “reliable” source of drinking water. However, the massive and extended use of groundwater for agricultural irrigation led to a lowering of the watertable, resulting in arsenic dissolution in water. [8] Today, as a maximum contaminant level for safe drinking water, WHO has agreed to lowering the recommended arsenic level from 0.05 to 0.01 mg/l or 10 PPB. In W EST BENGAL and BANGLADESH, about a million people may be consuming water in excess of 0.5 mg/l or 500 PPB, and wells have been found which contain as much as 10 mg/l or 10.000 PPB. This is 1.000 times the recommended limit. In [7] and [8], detailed charts of arsenic pollution in Bangladeshi wells are given. With skilled staff, good monitoring equipment and a well-managed facility, arsenic removal does not constitute a major problem in large-scale water treatment. Problems appear when trying to accomplish facilities for small-scale or household purposes. Maintaining the facilities and monitoring the results appears quite critical, even as the known treatment methods show a high dependence on arsenic concentration. Due to these problems and due to a negligible steam pressure of arsenic at ambient temperature, multi-effect humidification as a proven reliable desalination process needing low maintenance shows a good feasibility for removing arsenic from contaminated water. Experiments on Arsenic Removal As can be seen in [8], a widespread arsenic pollution average of 1.000 PPB is reached. This concentration was chosen for a feasibility study. For simulation of arsenic well water, pure arsenic (III) oxide (99,996%) was dissolved in deionized water with a total electrical conductivity of 139 µS/cm. The GOR ME 30 laboratory distillation plant at ZAE BAYERN is containing a total water volume of 150 l. In order to obtain a total feed water concentration of 1.000 PPB, 150 mg of arsenic (III) oxide had to be dissolved. In order to improve arsenic solubility in pure water, the solution was treated according to volumetric analysis standard methods [9] with NaOH and H2SO4. For laboratory tests, feed water and the two resulting mass currents brine and distillate were recirculated while cooling the brine. Samples of 40 ml were drawn off the distillate flow. Four different operating states were investigated by varying the evaporator inlet temperature and evaporator load flow. Feed water before and after the test series was analyzed. Arsenic analysis was carried out by TECHNICAL UNIVERSITY OF MUNICH, LEHRSTUHL FÜR W ASSERGÜTE UND ABFALLWIRTSCHAFT according to EN ISO 11, DEV D 18. Table 1 shows the experimental results: Table 1: Results of Arsenic Analysis Feed Water Start 254 l/h 25°C → 80°C 256 l/h 25°C → 85°C 420 l/h 30°C → 85°C Feed Water End Arsenic Concentration 818 PPB < 5 PPB < 5 PPB < 5 PPB 738 PPB Electrical Conductivity 160 µS/cm 1 µS/cm 1 µS/cm 1 µS/cm 160 µS/cm Distillate Flow 15 l/h 18 l/h 26 l/h The results for three different operation parameters show clearly, that the arsenic level can be reduced to a level lower than the detection limit of 5 PPB arsenic. Within detection accuracy, there seems to be no relation between feed water mass flow, evaporator inlet temperature and arsenic concentration in the distillate. By this, the feasibility of arsenic removal with the GOR multieffect distillation process was proven. Further experiments investigating a possible dependence of feed water and distillate arsenic concentration are on the way. CONCLUSIONS In the paper, a short overview on the worldwide water situation as well as on conventional desalination technologies was given. Two small-scale, autonomous plants for stand-alone operation in developing countries were described in detail and experimental results were discussed. The AQUASOL flash evaporation plant yields a daily production of 30-40 liters per day. The specific energy consumption has been determined at 1 kWh/ldistillate. Two experimental plants have been investigated and were working in a satisfactory way. One autonomous plant was tested on the solar experimentation field of TUM in GARCHING. Main problems were the high energy consumption, the need of seawater resistant steel qualities due to high-temperatures and a complicated controlling device. Further investigations have to aim at enhancing the air humidification rate for obtaining a lower specific energy consumption and at gaining mass manufacturing maturity. With the GOR multieffect humidification plant, a remarkably lower specific energy consumption of 100 kWh/m3distillate can be realized. The GOR plant is nearly maintenance free and has proven its reliability in two demonstration plants in FUERTEVENTURA (CANARY ISLANDS, SPAIN) and with 24 hour thermal storage system in SFAX, TUNISIA. The estimated distillate costs using solar collectors as heat source are 20 US$/m3. Due to the W EST BENGAL and BANGLADESH tube-well groundwater contamination with arsenic, experiments on arsenic removal with the GOR desalination plant were carried out. Therefor, the situation in W EST BENGAL and BANGLADESH was briefly discussed, and the experiments with a GOR ME 30 laboratory plant were described in detail. In preliminary experiments, multieffect humidification was found to be a suitable process for removing arsenic from contaminated wellwater. The outstanding advantage of this process is the fact, that distillate arsenic concentration is no function of feed water concentration. By this, monitoring of feed water and distillate is not necessary and low maintenance of the plant is guaranteed. REFERENCES [1] J. Ayoub et al., Water Requirements and Remote Arid Areas: The Need for Small-Scale Desalination, Desalination, vol. 107, 1996 [2] A. Walthes, Examination of a New Sea-Water Desalination System, Final Report EUVT-TUM DA 97/12, 1997 [3] L. Giagdzoglou, Examination of a Solar Sea-Water Desalination System, Final Report EUVT-TUM DA 98/5, 1998 [4] U. Frei, T. Häuselmann, F. Flückinger, R. Frey, Leistungsdaten thermischer Solarkollektoren, Technikum Rapperswil, Prüf- und Forschungsstelle Solarenergie, April 1994 xxx [5] H. Müller-Holst, M. Engelhardt, W. Schölkopf, Small Scale Thermal Sea Water Desalination Systems for Decentralized Use: Optimization of System Design by Simulation, Desalination vol. 122, pp. 255-262, 1999 [6] H. Müller-Holst, M. Engelhardt, M. Herve and W. Schölkopf, Solarthermal Seawater Desalination Systems for Decentralised Use, 6th Arab International Solar Energy Conference, Muscat, 1998 [7] www.hvr.se [8] www.dainichi-consul.co.jp [9] G. Jander, K. Jahr, Maßanalyse, 14. Auflage, Walter de Gruyter, Berlin/New York, 1986