TonenGeneral Sekiyu / EMG Marketing / Tonen Chemical Corporation

advertisement

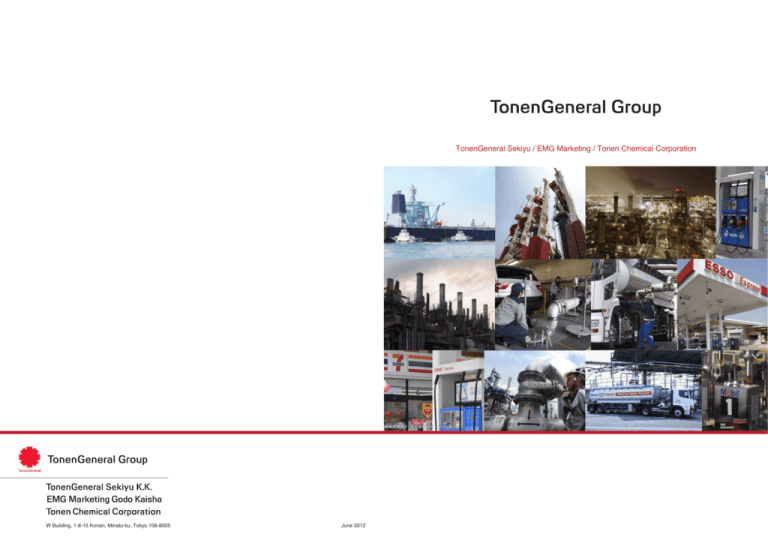

TonenGeneral Sekiyu / EMG Marketing / Tonen Chemical Corporation W Building, 1-8-15 Konan, Minato-ku, Tokyo 108-8005 June 2012 Introduction The TonenGeneral Group In June 2012, TonenGeneral Sekiyu K.K. and EMG Marketing Godo Kaisha (formerly ExxonMobil Yugen Kaisha) began operations as part of a new integrated production and sales group owned primarily by Japanese shareholders. The significance of the restructuring can be better understood by looking back at the Group’s 120-year history. Standard Oil Company of New York (Socony) opened its first Japanese branch in Yokohama in 1893 to import and sell kerosene at a time when kerosene lamps were still used for lighting. Vacuum Oil Company also opened a branch in Yokohama that same year. Vacuum Oil’s high-grade lubricants and technical services were factors in bringing Japan’s textile spinning industry to world prominence. The eventual sale of petroleum products under the Esso and Mobil brands also originated with Socony and Vacuum Oil. Meanwhile, domestic oil companies established Toa Nenryo Kogyo in 1939 through joint capital investment to manufacture aviation gasoline and aviation lubricants, then regarded as high-tech products. Toa Nenryo Kogyo, an oil refining company, founded Tonen Sekiyu Kagaku in 1960 to expand its business into the petrochemical industry during the high-growth period of the Japanese economy. Another event that contributed to our history was the establishment of General Bussan, originally the fuel department of Mitsui & Co. until it was made independent with the dissolution of the zaibatsu conglomerates in 1947. The company later became involved in petroleum refining and the sale of petroleum products under the General brand. These three strands of our history came together with the formation of the ExxonMobil Japan Group in 2000. However, the ExxonMobil Japan Group had a complicated capital structure: ExxonMobil Yugen Kaisha was wholly owned by ExxonMobil, while TonenGeneral Sekiyu, listed on the First Section of the Tokyo Stock Exchange, was partially (50.02%) owned by ExxonMobil Yugen Kaisha. The new TonenGeneral Group was created in June 2012 to respond to these circumstances by integrating refining and sales with TonenGeneral Sekiyu at its core. What had been a global organization divided vertically by function and operation was transformed into an integrated, self-sufficient organization within Japan. This evolution also means the Group has shifted to primarily Japanese ownership after having been foreign-owned for the majority of its existence. The Group now has the most efficient management structure in its 120-year history. Since the foundation of the ExxonMobil Japan Group, we have learned and witnessed firsthand what a global company should be. The expertise obtained from our past experience is the essence of our organization. Into this, we have integrated a management style suitable for the Japanese market. With a global knowledge base, the new Group is capable of responding to market needs faster than ever before. Leveraging the world’s most advanced technology and expertise, the new TonenGeneral Group strives to provide superior services grounded in actual conditions in Japan, as we continue to provide a stable supply of petroleum and petrochemical products. Thank you for your continued support. June 1, 2012 2 EMG Marketing Godo Kaisha TonenGeneral Sekiyu K.K. President Representative Director, President TonenGeneral Sekiyu K.K. Jun Mutoh Tonen Chemical Corporation President TonenGeneral Sekiyu K.K. Representative Director, Vice President Director Takashi Hirose Yasushi Onoda 3 Management Policy Pursuing the benefits of a new structure while maintaining our good practices Effective management policy maintained Our goals under the new structure • Continuing flawless operations The Group policy of maintaining our industry-leading safety and environmental record while continuing flawless business operations remains unchanged. • Integrated management of production and sales Greater integration of production and sales operations results in closer coordination among departments, enabling efficient management that can respond quickly to changes in the domestic business environment. • Consistent business management We have maintained our consistent business management basics including high standards of corporate ethics, effective corporate governance and performance and transparent financial reporting. • Rigorous financial discipline We continue to apply stringent investment standards and pursue self-help efforts as we strive to improve efficiency and maintain our healthy financial foundation. • Fostering outstanding human resources We are proud of our highly capable employees, who maintain a strong sense of responsibility and ethics. We remain committed to fostering outstanding human resources. • Shareholder-focused management We have maintained our shareholder-focused management policy ensuring superior competitiveness and capital efficiency to provide stable dividends. Main consolidated/affiliated companies (as of June 1, 2012) 100% 100% TonenGeneral Sekiyu K.K. TonenTechonology Godo Kaisha Use of fuel brands TonenGeneral Kaiun Yugen Kaisha 100% 50% Lubricants business alliance • Use of Mobil brands (e.g. Mobil 1) • Production and quality control technology • Joint research and development • Use of ExxonMobil’s global network for products and base oils Tonen Chemical Corporation 25% • Expansion of our stable operating base We continue to produce stable revenues and cash flow through the combination of petroleum refining, petrochemical and fuels marketing businesses, enabling the base for implemention of the above initiatives. Continued collaboration with ExxonMobil Chuo Sekiyu Hanbai K.K. 75% Nippon Unicar Company Limited Tonen Chemical Nasu Corporation 35% 99% 4 100% • Greater competitiveness We seek investment opportunities that suit the Japanese business environment to strengthen cost competitiveness and expand earning opportunities. We also participate in joint marketing with domestic business partners to strengthen our competitive edge in marketing petroleum products. We are also promoting greater cooperation with other companies at petrochemical complexes and effective investment in energy conservation measures. Technical support Shimizu LNG Co., Ltd. EMG Marketing Godo Kaisha 50% Kyokuto Petroleum Industries Godo Kaisha Consolidated subsidiary • Refining • Chemicals • Management system Supply cooperation • Crude oil • Feedstocks • Product import and export Equity method affiliate 5 Corporate History Integrated refining and marketing operations as a Japanese company after 120 years Ⅰ 1893 Vacuum Oil (U.S.) Japan branch Overview of capital restructuring Socony (U.S.) Japan branch As demand for kerosene and lubricants increased, Socony and Vacuum Oil opened Japanese branches in Yokohama in 1893. Prewar 1932 Socony-Vacuum (U.S.) Japan branch 1934 Stanvac (U.S.) Japan branch TonenGeneral Sekiyu acquired 99% of EMG Marketing Godo Kaisha (the former ExxonMobil Yugen Kaisha), entering into a new partnership with ExxonMobil. ExxonMobil remained the principal shareholder with 80 million shares in TonenGeneral Sekiyu. Then General shareholders Now ExxonMobil General shareholders ExxonMobil 80 million shares 49.5% (approx.) ⅠI World War II and postwar Toa Nenryo Kogyo K.K. (changed to Tonen K.K. in 1989) 1939 1947 General Bussan Partnership between Toa Nenryo Kogyo and Stanvac 1949 1958 ⅠII General Sekiyu Japan’s era of rapid growth Mobil Sekiyu K.K. 50.5% (approx.) 99% Directly owned 1% EMG Marketing G.K. Indirectly owned Note: Percentages (%) denote voting rights. TonenGeneral Group In 1963, Mobil Sekiyu and Mitsui Oil invested equally in the establishment of Kyokuto Petroleum Industries, a petroleum refining specialist. TonenGeneral Sekiyu Petroleum refining, production & sales of petrochemical products Kawasaki, Sakai and Wakayama Refineries Tonen Chemical: Kawasaki Plant EMG Marketing Kyokuto Petroleum Industries: Chiba Refinery 50% Esso Sekiyu K.K. TonenGeneral Sekiyu K.K. 2000 With the merger of Exxon and Mobil in 1999, the Japanese companies they had invested in were also restructured. Fuels marketing Tonen and General Sekiyu merged to become TonenGeneral Sekiyu. Lubricants ExxonMobil Yugen Kaisha V Capital restructuring of TonenGeneral Sekiyu and ExxonMobil Yugen Kaisha TonenGeneral Sekiyu K.K. Esso Sekiyu and Mobil Sekiyu were established with the dissolution of Stanvac. Kyokuto Petroleum Industries K.K. ⅠV 2002 22% (approx.) ExxonMobil Yugen Kaisha TonenGeneral Sekiyu K.K. Toa Nenryo Kogyo formed a partnership with Stanvac to introduce Standard Oil technology. Stanvac acquired 51% of Toa’s shares (later reduced to 50%). Distribution Restructuring of the ExxonMobil Group 78% (approx.) 100% The new structure allows for the integrated management of production and sales as shown below. Esso Standard Sekiyu K.K. 1963 1982 As a result of the dissolution of zaibatsu groups in Japan, the fuel department of Mitsui & Co., Ltd. went independent as General Bussan (later General Sekiyu K.K.) and was certified as a motouri. Tonen Sekiyu Kagaku (now Tonen Chemical Corporation) 1960 1961 In 1939, Toa Nenryo Kogyo was founded jointly by eight Japanese petroleum companies to produce aviation gasoline and lubricants. 1 terminal (Shimizu) Wakayama Lube Oil Blending Plant 8 terminals (Including Shiogama, Nagoya and Fukuoka) Tsurumi Lube Oil Blending Plant ExxonMobil Yugen Kaisha became EMG Marketing Godo Kaisha. 2012 Kyokuto Petroleum Industries (G.K.) EMG Marketing (G.K.) TonenGeneral Group Integrated management as the TonenGeneral Group with TonenGeneral Sekiyu’s acquisition of 99% of EMG Marketing Godo Kaisha shares. Note: (G.K.): Godo Kaisha 6 7 Business Overview Bringing the best to Japan The TonenGeneral Group maintains a petroleum supply chain from the transport and refining of crude oil to the manufacture, distribution and sale of products. P10-13 Crude oil transport Crude oil used by the Group is transported safely and efficiently from various regions including the Middle East, Russia, West Africa, Australia and Southeast Asia to our four refineries in Japan. Refining and manufacturing With safety as our highest priority, our refineries and chemical plants produce LPG, gasoline, naphtha, kerosene, diesel oil and other petroleum products, as well as chemical products, at low cost using advanced refining and production technology and rigorous quality control systems. P14-21 Distribution Sales Petroleum and petrochemical products produced at our refineries are transferred to various regions and distributed to customers. We are committed to safe and efficient operations. Our service stations make full use of ExxonMobil’s expertise. They provide fuels, lubricants, petrochemical products and services of the highest global standards to meet the needs of our customers. Research and engineering TonenGeneral Research Center specializes in research and development for lubricants and fuels Since its establishment more than 70 years ago, our laboratory has developed a number of advanced, high-performance lubricant products. Through joint research with auto manufacturers we offer passenger vehicle lubricants that can improve fuel efficiency, reliability and ease of use. We also offer differentiated products that contribute to the development of environmental technologies for automobiles. We work with ExxonMobil in lubricant research and development. In fuels, we continuously seek sound, science-based solutions for fuel quality issues and energy-related challenges. This leads to our active engagement in joint research and study programs funded by the industry and the government from the planning phases. Based on these activities, we proactively make recommendations to related industries and to the government. We also provide technical support in fuel quality and performance to our refineries and fuels marketing segment. The TonenGeneral Group imports the optimal mix of crude oils and feedstocks from around the world. We efficiently produce a wide range of petroleum and petrochemical products at oil refineries in Japan and export some of these products overseas. We also maintain an integrated supply chain of importing, refining and manufacturing through to distribution, sales and exporting. We apply the world’s most advanced technologies and expertise to all of our business activities to bring the best to Japanese consumers. 8 Engineering operations performed by our process engineering division The Group regards engineering as a pillar of our corporate activities. Our engineering division has specialists in process, equipment and project-related technical fields. These specialists plan and carry out projects using the latest information on domestic and global technology as well as technological support from ExxonMobil. Our engineers are committed to ensuring the safe, reliable and high-performance operation of existing facilities. 9 Refining & Manufacturing Safety-focused, low-cost production system for fuels, lubricants and chemicals One of Japan’s largest refineries Kawasaki Refinery Kawasaki Refinery is located on the Keihin oceanfront, a convenient land and sea transport site adjacent to the Tokyo metropolitan area, Japan’s largest consumer market. Kawasaki Refinery is our largest refinery with one of the highest refining capacities in the country. It also has the largest FCC (fluid catalytic cracker) in Japan and the only H-Oil (heavy oil cracking/desulfurization unit) in the country. The refinery is situated on the same site as the Tonen Chemical Corporation plant, enabling mutual product supply, sharing of facilities and organizational integration for a highly efficient production system. Refineries and terminals Shiogama Terminal Fushiki Terminal Kyokuto Petroleum: Chiba Refinery Sakai Refinery Hiroshima Terminal Fukuoka Terminal Kawasaki Refinery Shimizu Terminal Nagoya Terminal Alkylation unit Distillation column Hydrodesulfurization unit Crude oil Atmospheric pipestill The fundamental role of our production segment is to manufacture petroleum and petrochemical products from the world’s best crude oil and intermediate products at our four refineries in Japan. With safety as our highest priority, we continue to pursue greater added value as we carry out our crude procurement and product export operations. Manufacturing process LPG Catalytic reformer Benzene extraction unit Kerosene/diesel hydrodesulfurization unit Gasoline, naphtha, xylene, etc. • Automotive fuel • Chemical feedstocks Kerosene/ jet fuel • Fuel for kerosene heaters • Jet fuel Diesel Fuel oil A • Bus/truck fuel • Fuel for small marine vessels Fuel oil C • Industrial fuel • Fuel for power generation • Marine fuel FCC gasoline desulfurization unit Vacuum gas oil desulfurization unit Vacuum pipestill Fluid catalytic cracker (FCC) Heavy oil cracking/ desulfurization unit (H-Oil) • Fuel for portable gas stoves • Taxi fuel • Chemical feedstocks Common petroleum products Wakayama Refinery Komatsushima Terminal 10 Miyazaki Terminal Takamatsu Terminal 11 Refining & Manufacturing Largest, highly energy-efficient production and shipping base in western Japan Integrated production center provides flexible support for global and domestic needs Sakai Refinery Wakayama Refinery is located in a quiet residential district adjacent to the rich fishing waters of the Kii Channel in a region known for the production of Arida tangerines. In these surroundings, the refinery maintains the world’s highest level of operational safety with the utmost attention to environmental protection. The refinery, which has a long history, is an integrated production center for a number of petroleum products including gasoline, lubricants and aromatics in addition to special products such as aviation and automotive test fuels. Taking advantage of its large number of tanks and its marine shipment facilities located in a good harbor, the refinery makes a great contribution to domestic energy supply while responding flexibly to export needs. Sakai Refinery is located in the Sakai-Senboku coastal industrial area in Osaka, the largest consumer market in western Japan. In addition to refining, this integrated site also manufactures chemical products such as paraxylene and propylene. The refinery also pursues synergy effects with the supply of feedstocks via pipeline to and from other companies’ refineries in the same industrial complex. At the shipping terminal, the largest of its kind in the Kansai area, the first bottom loading system in Japan has been implemented for better environmental protection, improved safety and faster loading. With one of the best energy efficiency ratings in Japan, the refinery maintains a competitive edge thanks to its excellent location as well as its environmentally conscious, safe and efficient facilities and operations. 12 Wakayama Refinery Chiba Refinery (Kyokuto Petroleum Industries) Wakayama Refinery Lube Oil Blending Plant This refinery is located in an industrial complex in the Keiyo region. Kyokuto Petroleum Industries is a limited company established with equal investment by the TonenGeneral Group and Mitsui Oil. This plant blends base oil produced at Wakayama Refinery with additives to produce lubricants, which it puts in drums, pails and other containers for shipment. 13 Fuels Marketing Trusted Brands: Esso, Mobil and General Retail The TonenGeneral Group carries out common initiatives nationwide for the Esso, Mobil and General brands to provide customers with a stable supply of quality petroleum products at reasonable prices. We are also leading the industry in the expansion of self-service stations and differentiating our services with ingeniously designed service stations under the Express brand. We continue to operate our service stations with attention to environmental and safety considerations while accurately responding to customers’ ever-changing expectations. Standard Oil created the Esso oval in 1933. The name “Esso” was coined by spelling out the pronunciation of the initials S and O. The TonenGeneral Group’s business is supported by trusted brands. We also offer a wide range of services that provide flexible support for society’s needs. We supply a variety of reliable products including fuels, LPG, lubricants and chemicals. One of the Group’s strengths is adopting the world’s best practices with the motto “Customers Come First”. 14 West Japan Branch The red and blue General logo was created in 1967. Symbolizing the blazing energy and speediness of a wing, it expresses a sense of power suitable for the image of an oil company. Sapporo Satellite Office Sales Centers Osaka Branch No.1 & No.2 The bright blue logo with the letter O in red was created in 1966. It is highly visible even from long distances and is perceived as a symbol of trust, energy, enthusiasm and action. East Japan Branch Tokyo Branch No.1 & No.2 Nagoya Branch Takamatsu Satellite Office Hiroshima Satellite Office 15 Fuels Marketing Self-service Express brand Industrial & wholesales Express self-service stations operate under the concept of the quickest, easiest service in the cleanest, most comfortable facilities. For the further evolution of our brand value, we boost the tangible and intangible aspects of our service by enhancing sales promotion programs, improving customer service and ensuring clean environments at our service stations. 16 In our industrial & wholesales segment, we provide a stable supply of industrial fuels, LPG and other products at competitive prices. We also continue to hold seminars focusing on human resource development, a challenge we share with our dealers. Convenience of Express Synergy Card We implement a range of initiatives to maintain and strengthen the top brand position of Express, which customers support more than any other brand. This personal-use credit card can be used at Esso, Mobil and General service stations. It provides a variety of special offers based on amount of purchases, including discounts on fuel and an annual fee waiver service. Speedpass Express Wash Seven-Eleven ExxonMobil’s original payment device that can be used at affiliated service stations. Refueling or car wash operations can be initiated by simply holding the device over the panel attached to the pump or car wash. It’s a fast and secure way to complete payments. Express Wash is equipped with a uniformlydesigned, easy-to-use operation panel. The innovative drive-through car wash, based on a foam jet design, is highly acclaimed by customers. We operate alliance sites with Seven-Eleven Japan, a top brand and leader in the convenience store industry. These sites offer convenience to our customers while also creating a new brand image for self-service stations. Video Pump Mobil 1 Center Doutor Coffee Shops These fuel pumps feature high-luminance color LCD touch panels. The menu screen displays self-service operation guides and also enables car wash reservations or orders to Doutor Coffee Shops located on the same sites. At Mobil 1 Centers, professional service station staff provide quick and convenient oil change service. Customers can choose from a variety of oils, including Mobil 1, our synthetic engine oil. We operate alliance sites with Doutor Coffee Shop, which has strong brand power. The sites provide customers with quality services and convenience, including original seasonal products and clean, appealing store environments. Industrial fuels LPG We sell a wide range of products manufactured from crude oil through distribution channels other than service stations. For example, we supply diesel oil mainly to public transport operators and the logistics industry. Kerosene and fuel oil A are now not only used for heating, but are more increasingly supplied to cogeneration systems at plants and hospitals. Fuel oil C is used as a heat source for boilers at thermal power stations and plants and also as fuel for large marine vessels. The former General Sekiyu (now TonenGeneral Sekiyu) was the first Japanese company to import LPG products from the Middle East, paving the way for increased LPG consumption in Japan. Kawasaki, Sakai and Wakayama Refineries are the main centers for supplying LPG to bottling terminals and industrial plants nationwide. Kawasaki and Sakai Refineries, both located close to major markets, have their own import terminals, contributing to a stable supply of LPG. Marine fuel Aviation fuel We have supply bases in Tokyo and Osaka Bays, Japan’s two key bay areas. These bases provide a stable supply of high-grade fuels produced at the Group’s adjacent refineries. Our quality control team strives to maintain consistent product quality. The Group provides high-quality aviation fuels and customer services. Along with our outstanding operations at airports, we supply aviation fuels, mainly jet fuel, to major domestic and international airlines and public authorities. 17 Lubricants & Specialties Consolidation of world-class technologies High-grade oils The Group offers an extensive lineup of oils, including the synthetic engine oil Mobil 1, to meet the needs of our customers in automotive, industrial, aviation and marine applications. Automotive lubricants Aviation and marine lubricants Industrial lubricants Base oil and specialties Mobil-brand industrial lubricants have led lubricant technology for over 100 years. Our vast expertise and experience achieved through research in this field are used extensively to develop lubricants designed for advanced industrial machinery. Such lubricants make great contributions to improved equipment productivity and energy conservation. Striving to improve productivity and conserve energy, we have created the synthetic lubricant Mobil SHC using leading-edge technology. Mobil-brand industrial lubricants, which provide superior technological support and are recommended by major international machinery manufacturers, demonstrate their strong performance particularly in the manufacturing and electricity industries, including wind power generation. Through our strategic partnership with ExxonMobil, we produce high value-added specialty products using an advanced quality control system. We work with the refining department to ship wax products nationwide, while making active efforts to expand exports to global markets. We export base oils mainly to Asia via ExxonMobil’s distribution channels. Mobil-brand lubricants supported technological evolution even before the first gasoline engine was invented. Mobil has played important roles in a number of famous historical events: the Wright brothers' first flight, space station launches and Formula One engines from the very first to the latest models. Mobil automotive lubricants meet the latest standards set by API (American Petroleum Institute), ILSAC (International Lubricant Standardization and Approval Committee), ACEA (European Automobile Manufacturers Association) and other organizations and protect engines effectively to help vehicles achieve the best performance in all situations from routine car maintenance to use in harsh conditions. Mobil 1, in particular, is a synthetic engine oil manufactured using high-performance base oil and advanced additive technology, and continues to be the oil of choice for customers around the world. In addition to the domestic sale of Mobil-brand automotive lubricants like Mobil 1, we are also involved in the joint development of next-generation products with major Japanese auto manufacturers to supply high-quality oils to better meet the latest needs of customers. 18 In our lubricants and specialties segment, we sell automotive lubricants with world-class brand power earned through our support of Formula One and other initiatives. Other products include industrial lubricants recommended by major international machinery manufacturers, aviation and marine lubricants that support the supply of high-quality products through a reliable technical support system and base oil and specialty products manufactured and sold in cooperation with our refining segment. Mobil 1 is an automotive lubricant used as a factory fill oil by major international auto manufacturers. Plants Mobil and Exxon brand high-grade aviation and marine lubricants are used throughout the world and quality service is provided to customers in Japan by the Group. We supply a wide variety of aviation lubricants, including engine oil, hydraulic oil and grease designed for aircraft. With a range of technical support to offer, we have earned the trust of customers all over the world. Our products, recommended by engine and airframe manufacturers, contribute to safe aircraft operation. We supply domestic marine customers with a range of lubricants from engine oil and hydraulic oil to gear oil and grease. Our quality products and services, including synthetic oils that help reduce the total cost of vessel operation, meet the needs of our customers. For international marine customers in Japan, the Group offers sales and technical support services through a strategic partnership with ExxonMobil, making a significant contribution to safe, efficient vessel operation. Tsurumi Lube Oil Blending Plant Tsurumi Lube Oil Blending Plant Wakayama Lube Oil Blending Plant Located in the northeastern part of Yokohama, the heart of the Keihin industrial area, this lube plant is within the greater Tokyo metropolitan area, Japan’s largest consumer market. The plant specializes in lubricants for passenger vehicles and various types of machinery. It carries out coordinated operations from manufacturing to delivery. Mobil 1, a synthetic engine oil, is one of the key products shipped from this plant. Through cooperation with neighboring companies, we also make efforts to preserve the environment and improve safety, while actively participating in a variety of community-based activities. 19 Chemicals Competitive product range through integrated operations with refining Quality chemicals are indispensable for end products used in every aspect of our lives, from automotive products to cosmetics. We contribute to society as a whole by providing a stable supply of quality chemicals not only to the domestic market but also to the rapidly growing Asian market. Basic chemicals With our competitive edge based on synergy with petroleum refining, we provide both the domestic and regional markets with a stable supply of olefins (ethylene, propylene, butadiene, etc.), which are the building blocks of chemical materials used in aircraft and automobile parts, electric and electronic components, food packaging and household items, along with aromatics (paraxylene, ortho-xylene, benzene, etc.) used as components in polyester fiber, PET bottles and nylon fiber. Petroleum resins We manufacture and sell both hydrogenated and non-hydrogenated petroleum resins. Our products, with excellent cold resistance, heat stability, adhesiveness, transparency and gas barrier properties, demonstrate high functionality that meets the needs of our customers. Our products are used for a wide range of applications including industrial adhesives, high-performance tapes, fuel-efficient tires and disposable diapers. Demand is expected to increase significantly, especially in developing countries. Specialty chemicals Methyl ethyl ketone, a highly soluble and functional chemical, is used for a number of applications in diverse fields, ranging from solvents for paint and printing ink and resin treatment for electronic components to film molding for optical panels and chemical process solvents. Hydrocarbon solvent, which is manufactured in the petroleum refining facilities, is added to car paint, agricultural chemicals, metalworking oil and other products. Such specialty chemicals work behind the scenes to enhance the convenience of our lives. Our chemical plants are located on the same sites as our refineries, where they can readily obtain refinery-produced feedstocks for their manufacturing operations. The synergy generated by the integration of our chemical and refining operations enables TonenGeneral Sekiyu and Tonen Chemical to maintain strong cost competitiveness in the chemicals market. 20 Refineries Sakai Refinery Kawasaki Refinery Wakayama Refinery 21 Corporate Social Responsibility Contributing to society as a good corporate citizen Safety The Group introduced the Operations Integrity Management System (OIMS) in the 1990’s as its safety, health and environment management system and has been implementing improvements ever since. In 2000, the Group also introduced the Loss Prevention System (LPS), which focuses on human behavior to prevent losses (human-related injuries, damage to equipment and assets, etc.) caused by unsafe actions. LPS has produced significant results in our daily activities. Health The Group appoints industrial physicians and industrial hygienists to assess potential adverse factors scientifically and takes appropriate measures to minimize any impact on the health of employees and contractors as well as on the communities in which it operates. Workplace • Human resource development Fair and subjective performance evaluations are vital for human resource development. Our managers and employees share the responsibility of managing the progress of short-term operational goals and creating long-term career plans, as well as drawing up and carrying out training plans through regular communication. • Diversity In rapidly changing times, strong creativity and ideas based on diversity are essential for the sustainable development of any company. The Group respects the individuality of every employee and strives to provide a workplace that can maximize their talents. The Group also promotes the active recruitment of female employees, who have established their own internal activity network. The TonenGeneral Group believes that a company is also a member of society. Therefore, we strive to be a good corporate citizen in every community in which we operate. It is very important for the Group to contribute to the development and vitalization of these communities, while maintaining high standards of corporate conduct and complying with all applicable laws and regulations. 22 23 Corporate Social Responsibility Corporate governance Environmental activities Social contributions The Group complies with all applicable laws and regulations and operates its business through sound corporate governance, as we believe the methods used to achieve business results are as important as the results themselves. The Group’s policies for conducting its business operations are clearly stipulated in its Standards of Business Conduct, which contains 16 basic policies and various guidelines. The Group uses the word “controls” as a general term meaning the direction, management or supervision of a range of business activities. We constantly monitor our compliance status through a thorough controls structure using two controls systems: the System of Management Control (SMC) and the Controls Integrity Management System (CIMS). • Environmental policies The Group maintains the highest level of responsibility for all environmental aspects of its operations. Under the slogan “Protect Tomorrow. Today.”, we strive to eliminate incidents that impact the environment and continuously improve our environmental performance while meeting all environment-related legal requirements. The Group believes that it has the very important social responsibility of providing a stable supply of energy, maintaining safety and trust and further contributing to the development and vitalization of the communities where we operate. Based on this concept, we deepen cooperation with communities through a variety of social contribution and cultural activities in fields such as environmental preservation, health and welfare, regional exchange, education, the arts and culture. Examples of some of these activities include: • Environmental business planning Our refineries, chemical plants and distribution segment create annual environmental business plans to achieve their goals. They review the results of previous plans, predict future environmental and business situations based on current circumstances, assess public issues and regulatory trends and create capital investment plans that require concrete short- and long-term planning for environmental preservation. Head office: Children’s Culture Award and Music Awards Kawasaki Refinery: Blood drive Job Shadow program Sakai Refinery: Sakai City Opera dress rehearsal concert • Addressing climate change risks We have always made innovative, industry-leading efforts in energy conservation initiatives at our refineries and chemical plants. As a result, the Group’s refinery energy consumption unit (oil equivalent energy volume used per CDU equivalent throughput) is consistently among the best in the industry. Charity Run Changes in energy consumption unit at three TonenGeneral Group refineries 11 10.9 9 Rate of improvement since 1990: 14.2% 8.58 9.07 7.78 7 1990 2000 Unit energy consumption = at refineries Wakayama Refinery: Petroleum industry average Tangerine orchard patrol Low Efficiency Three TonenGeneral Group refineries Phoenix Tennis School Support for the Tonen International Scholarship Foundation and General Sekiyu Research and Development Encouragement and Assistance Foundation High 2010 Energy consumption (oil equivalent, KL) Throughput (CDU equivalent, thousand KL) Kansai Refining and Sales: Adopt Forest Nijozan Voluntary beach cleanup (Forest conservation activity on Mount Nijo in Taishi-cho, Osaka) 24 25 Corporate Social Responsibility Support for areas affected by the Great East Japan Earthquake Immediately after the Great East Japan Earthquake struck in March 2011, the Group acted in accordance with the disaster response plan for the entire organization. Specifically, the Group promptly set up emergency headquarters to ensure the safety of employees and their families in affected areas, established a secure system to supply petroleum products, formed a joint support network with the government and the industry and then put all these measures into practice. • Prompt recovery of the product supply system After the earthquake, all oil supply facilities on the Pacific coastline in the Tohoku region were temporarily out of operation. The Group, however, took immediate action to restore the Shiogama terminal in Miyagi Prefecture. Consequently, it took only nine days after the earthquake to resume shipment of petroleum products. The terminal played an important role as a fuel supply hub for the Tohoku region and was also used by other oil companies. • Emergency shipments of fuel in drums In response to a request from the Ministry of Economy, Trade and Industry, the Group shipped 1,000 drums of gasoline, diesel and kerosene (200 liters per drum) from the Wakayama Refinery to the disaster-stricken region from March 19 to 25. The fuels, shipped from filling facilities at the refinery, were first transported by land to the Air Self-Defense Force’s Iruma Base. From there, they were flown to evacuation centers in areas suffering from severe fuel shortages due to the disaster. • Installation of a temporary service station For more than one month after the quake, no service stations were in operation in Rikuzentakata in Iwate Prefecture. With the assistance of the Ministry of Economy, Trade and Industry and the Fire and Disaster Management Agency, the Group installed an unprecedented type of temporary service station using containers normally employed to transport specialty chemicals. The temporary service station was completed on April 21 and handed over free of charge to the city of Rikuzentakata the following day to serve the community as a fuel supply center. • Donation of 1 million liters of fuel The Group donated 100,000 fuel coupons to about 30 local governments in Iwate, Miyagi and Fukushima, the three prefectures most affected by the disaster, as a way of providing direct support to victims in the affected areas. Coupons could be exchanged for 10 liters of gasoline, diesel or kerosene at Group service stations. Local governments distributed the coupons in the most effective way according to their own requirements. 26