CHAPTER 22 DESIGN AND ANALYSIS FLOWCHARTS

advertisement

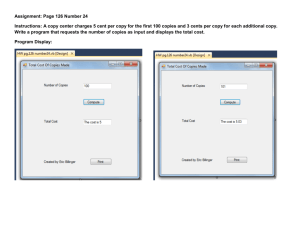

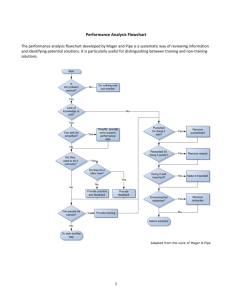

CHAPTER 22 DESIGN AND ANALYSIS FLOWCHARTS FLOWCHARTS To help the student and design engineer to prepare their own programs, flowcharts are given for most chapters. 1. Flowcharts 22.1, 22.2, and 22.3 explain the analysis of single, double, and T-sections (Chapter 3). 2. Flowcharts 22.4, 22.5, and 22.6 explain the design of single, double, and T-sections (Chapter 4). 3. Flowchart 22.7 explains the calculation of development length (Chapter 7). 4. Flowchart 22.8 explains shear design (Chapter 8). 5. Flowchart 22.9 explains the analysis of rectangular columns at balanced condition (Chapter 11). 6. Flowchart 22.10 explains the analysis of rectangular columns (Chapter 11). 7. Flowchart 22.11 explains the design of rectangular or square footings (Chapter 13). 8. Flowchart 22.12 explains the design for combined shear and torsion (Chapter 15). Given: b, d, As, f’c, fy Required: φMn Let ρ = As / bd No Yes ρ > ρmin (1) Yes Increase ρ ρ ≤ ρmax (2) a = Asfy/ (0.85f’cb) c = a / β1 εt = 0.003(dt – c)/c εt ≥ 0.005 φ = 0.9 φMn = φAsfy(d-a/2) End Flowchart 22.1 Analysis of single reinforced rectangular section. (1) ρ min = 3 f 'c / fy ≥ 200 / fy 87 (2) ρb = (0.85β1)(f’c / fy) 87 + f y 0.003 + f / E y s ρ max= ρb 0.008 No Reduce ρ Given: b, d, d’, As, A’s, f’c, fy Required: φMn Let ρ = As / bd, ρ’ = A’s / bd No ρ ≥ ρmin Increase ρ No Yes Yes ρ - ρ' ≥ K (1) f’s < fy f’s = fy Solve for c: A1c2 + A2c + A3 = 0 A1 = 0.85β1f’cb A2 = A’s(87 – 0.85f’c) - Asfy A3 = -87A’sd’ Yes No ρmin ≤ ρ-ρ’≤ρmax a=(As–A’s)fy/(0.85f’cb) Change ρ Calculate f’s < fy; ε’s = 0.003(c-d’)/c εt = 0.003(dt -c)/c f’s = Esε’s = 87 (c − d ') c Yes No εt ≥ 0.005 No εt ≤ 0.002 Yes φ = 0.9 φ = 0.65+(εt – 0.002)(250/3) (other members) a= φ = 0.65 (other members) ( As f y − A 's f 's ) 0.85 f 'c b φMn = φ[Asfy – A’sf’s)(d-a/2) + A’sf’s(d-d’)] Flowchart 22.2 Analysis of double reinforced rectangular section. 87 (1) K = (0.85β1)(f’c / fy)(d’ / d) 87 − f y (2) Refer to flowchart 22.1 to calculate ρmin and ρmax. End Given: b, bw, d, t, As, f’c, fy Required: φMn No Yes As ≤ As max (1) Yes Reduce As No As ≥ As min (2) For T-section, be is the smallest value of: Span / 4 or Center to center of adjacent slabs or (bw + 16t); t = slab thickness. For L-section, be is the smallest value of: Span / 12 or half clear distance to next web + web width or (bw + 6t); t = slab thickness Increase As Let a’ = Asfy/(0.85f’cbe) No εt =0.003(dt-c)/c εt ≥ 0.005 Enlarge section Yes Yes a’≤ t No T-section analysis Rectangular analysis a = a’ φMn = φAsfy (d - a/2) End Asf = 0.85f’ct(b-bw) / fy a = (As – Asf)fy/(0.85f’cbw) φMn = φ[(As – Asf)fy(d-a/2) + Asffy(d-t/2)] End Flowchart 22.3 Analysis of T- and L-sections. (1) As max = 0.6375(f’c/fy)[t(b-bw) + 0.375bwβ1d] (2) 3 fc' 200 As min = bwd ≥ bwd fy f y Given: Mu, f’c, fy Required: As Yes b and d are given Calculate Ru = Mu/(bd2) ρ= No Assume b (12-20) in. Or d / b ≈ 2 0.85 f 'c 1 − 1 − (2 Ru / 0.85 f 'c φ ) fy ρmin ≤ ρ ≤ ρmax (1) No Assume ρ. ρmin ≤ ρ ≤ ρmax or let ρ ≈ ρb / 2 Yes Calculate Ru: Ru = φρfy (1-ρfy/1.7f’c) As = ρbd Change section d = M u / Ru b As = ρbd Choose bars h = d+2.5 in. (one row of bars) h = d+3.5 in. (two rows of bars) Round h to the next higher inch. End Flowchart 22.4 Design of single reinforced rectangular section. (1) Refer to flowchart 22.1 to calculate ρ min and ρ max Given: Mu, b, d, d’, f’c, fy Required: As, A’s Calculate ρmin and ρmax (1) Calculate Ru max Ru max = φρmaxfy(1-ρmaxfy/1.7f’c) Calculate φMn = Mu1 as singly reinforced Mu1 = Ru maxbd2 No Yes Mu ≥ Mu1 Comp. steel is not required. As1 = ρmaxbd Mu2 = Mu - Mu1 Go to flowchart 22.4 As2 = Mu2 / φfy(d-d’) Total As = As1 + As2 As ≤ As max No εt =0.003(dt-c)/c εt ≥ 0.005 Yes Change section Yes f’s ≥ fy Check if comp. steel yields. Let a = As1fy / 0.85f’cb c = a / β1 Calculate f’s = 87(c - d’) / c No f's = fy A’s= As2 f's < fy A’s= As2fy/ f’s End End Flowchart 22.5 Design of rectangular sections with compression steel. (1) Refer to flowchart 22.1 to calculate ρ min and ρ max Given: Mu, b, bw, d, t, f’c, fy Required: As No Yes d is given Calculate Muft (total flange). a=t Cft = 0.85ϕf’cbt Muft = φ Cft(d – t/2) Assume a = t d = Mu / ϕ(0.85f’cbt) + t/2 Yes As = Mu / [φ fy (d - t/2)] If steel is high,assume a < t or a ≈ t / 2 d = Mu / (0.85φf’cba) + a/2 Mu ≤ Muft Rectangular section design, a ≤ t a = a’ T-section design, a>t Ru = Mu / bd2 Cf = 0.85f’ct(b – bw) Asf = Cf / fy ρ = (0.85f’c/fy)[1- 1 − 2 Ru / 0.85φ f 'c ] As = Mu / [φfy(d – a/2)] No Muf = φCf (d – t/2) Muw (web) = Mu - Muf As = ρbd Ruw = Muw / bwd2 ρw =(0.85f’c/fy)[1- 1 − 2 Ruw / 0.85φ f 'c ] As = Asf + Asw No Asmin≤As≤Asmax Or εt = (dt - c)/c ≥ 0.005 Change section Flowchart 22.6 Design of T- or L-sections. Asw = ρwbwd Yes As is OK Given: bw, d, f’c, fy, bars Required: Development length f 'c ≤ 100 psi Compression bars Tension bars (for no 7 and large bars) ldc = (0.02dbfy) / λ f 'c ldc ≥ 0.0003dbfy ld1 / db = ψ tψ e f y / 20λ f c' (for no-6 and smaller bars) ld1 / db = ψ tψ e f y / 25λ f c' ld = ldc*(Rs or Rs1, if applicable) ld ≥ 8 in. No Rs = As (required) / As (provided) Rs1 = 0.75 for spiral columns ld = 1.5 ld1 ≥ 12 in. Flowchart 22.7 Calculation of development length (1) c = clear cover s = clear spacing Is c ≥ db s ≥ db or s > 2db (1) Yes ld = ld1 ≥ 12 in. Given: bw, d, f’c, fy, Vu Required: shear reinforcement Vc = 2λ f 'c bwd φ = 0.75 No Yes Vu ≥ φVc/2 Yes No shear reinforcement is required Vu > φVc Vs = (Vu - φVc) / φ No Vs > 4Vc Av = VsS / fyd Or S = Avfyd/Vs Yes Vs > 2Vc S ≤ d/4 ≤ 12 in. End Flowchart 22.8 Shear Design. Yes Increase section No S ≤ d/2 ≤ 24 in. S ≤ Avfy / 50bw End No Choose minimum shear reinforcement. Av ≥ 50bwS / fy Av =0.75 f 'c (bwS/fy) S ≤ d/2 ≤ 24 in. Minimum stirrups no.3 at Smax Given: b, d, d’, As, A’s, f’c, fy Required: Pb, Mb, eb cb = 87d / (87 + fy) ab = β1cb f’s = [87(cb – d’) / cb] f’s ≤ fy (Ksi) Cs = A’s (f’s – 0.85f’c) Cc = 0.85f’cab T = Asfy Pb = Cc + Cs - T Mb = Cc(d – ab/2 – d’’) + Cs(d – d’ – d’’) + Td’’ eb = Mb / Pb End Flowchart 22.9 Balanced load, moment, and eccentricity for rectangular column sections (Use Ksi for f’c and fy; d’’ = distance from the plastic centroid to As). Given: b, d, d’, As, e Required: Pn, Mn No Yes e > eb Compression failure fs < fy a > ab φ = 0.65 Tension failure fs = fy a < ab 0.65 ≤ φ ≤ 0.9 Assume f’s = fy Solve for a: Aa3 + Ba2 + Ca + D = 0 A = 0.85f’cb/2 B = 0.85f’cb(e’ – d) C = A’s(fy– 0.85f’c)(e’– d + d’) + 87Ase’ D = -87Ase’β1d e’ = e + d’’, c = a / β1 Solve for a: Aa2 + Ba + C = 0 A = 0.425f’cb B = 2A(e’ – d) C = A’s(f’s– 0.85f’c)(e’– d + d’) - Asfye’ e’ = e + d’’, c = a / β1 Solve by trial or calculator No f’s = [87(c – d’)/c] ≤ fy fs = [87(d – c)/c] ≤ fy ε’s ≥ εy (1) f’s = fy f’s = [87(c – d’)/c] ≤ fy T = Asfs T = Asfy Cc = 0.85f’cab Cs = A’s(f’s– 0.85f’c) ≥ 0 Pn = Cc + Cs - T Mn = Pn e End Flowchart 22.10 Analysis of rectangular columns (Use Ksi for f’c and fy) (1) ε’s = 0.003(c-d’/c); εy = fy / Es Yes Given: PD, PL, H, qa, f’c, fy Column size c, and bars Assume footing depth h (in.) Let Wc = 150 pcf, Ws = 100 pcf qe = qa – h(150)/12 – (H - h)(100)/12 ; psf Footing area A = (PD + PL)/qe Side = A for square footing Or L x B for rectangular footing Choose L / B < 2 Pu = 1.2 PD + 1.6 PL qu = Pu / A Let average d = h – 4.5 in. Check two-way shear: d2 is the largest value of: d2 = Vu2/(4λ f 'c b0) d2 = Vu2/λ[(αsd/b0) + 2] d2 = Vu2/λ[(4/β + 2] Check one-way shear: d1 = Vu1/(2λ f 'c b) f 'c b0 f 'c b0 αs = 40, 30, 20 for interior, edge and corner columns b0 = 4(c + d) for square columns b0 = 2(c1+d) + 2(c2 + d) for rectangular columns φ = 0.75 Long direction MuL = 0.5qu (L/2 – c/2)2 Short direction MuS = 0.5qu (B/2 – c/2)2 Calculate AsL and AsS Choose bars and check ld Yes d = the larger of d1 and d2 h’ = d + 4.5 ≥ h If h’ < h, increase h and repeat. N1 = φ(0.85f’c)A1 (column) N2 = N1( A2 / A1 ) ≤ 2N1 φ = 0.65 Pn > N1 No Dowel bars Min. Asd = 0.005 A1 Use 4 bars Pex = Pu – N1 Asd = Pex/fy ≥ 0.005A1 Choose dowel bars and check ld in compression. End Flowchart 22.11 Design of rectangular or square footings . Given: b, h, Vu, Tu Required: Closed stirrups and A1 Let x0 = b, y0 = h, φ = 0.75 Let x1 = (b – 3.5 in.), y1 = (h – 3.5 in.) Acp = x0y0, Pcp = 2(x0 + y0) A0 = 0.85 x1y1 = 0.85A0h Ph = 2(x1 + y1) Let Q = (φλ f 'c )A2cp/ Pcp Yes No Yes Tu > 4Q Tu is neglected. Check for Vu (flowchart 22.7) Tu = 4Q for compability Tu Use Tu Yes No Tu > Q No (Vu / bw d ) 2 + (Tu Ph /1.7 A2 0 h ) 2 ≤ φ[(Vc / bw d ) + (8 f 'c )] Increase section At/S = Tn/(2A0fytcotθ) A1 = (At/S) Ph (fyt/fy) cot2θ A1 min = (5 f 'c Acp)/fy – (At/S) Ph (fyt/fy) Al min ≥ 25bw / f yt Min. bar diameter =0.042S ≥ no. 3 Total area of closed stirrups Avt = 2At + Av Avt ≥ (50bwS/fyt) (Av from shear) Spacing of stirrups = area of bar/Atot Max. S = Ph/8 ≤ 12 in. End Flowchart 22.12 Design for combined shear and torsion.