ED Craig's Resume Jan 08

advertisement

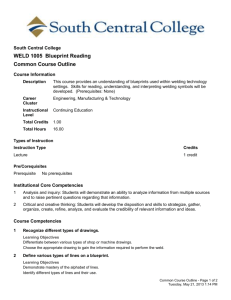

Resume: Edward F. Craig. “Weld Manager” Contact. E Mail ecraig@weldreality.com USA / Canadian and UK Citizen. My web site. www.weldreality.com. Address: Asheville. NC. 28804. Daytime / Evening Phone. 828 658 3574. Education: City Guilds. Stretford Tech College. UK. 1967: Canadian Welding Institute. Canadian Welding Institute. Linde / Union Carbide Training. Canadian Weld Institute. University of Wisconsin Dept of Engineering. Ohio State University. Dale Carnegie. Class Leader. J W Harris. Ohio State University. Thermal Dynamics. MK Products. Welding / Metallurgy. 2 year Program Welding Principles Practices. Course. Weld Quality / NDT. I taught this course. Automated MIG / TIG. Training Program Aluminum MIG / TIG Welding. Course. Weld Technology / Weld Metallurgy. Course. Robotics and Arc Welding. Course. Effective Speaking and Human Relationships. Advanced Brazing course. Course. Laser Welding / Cutting. Course. Advanced Plasma Weld / Cutting Course.. Orbital, GTAW Tube and Pipe Welding Course.. Present Employment: Since May 1998 to present. WeldTrain International. Asheville. North Carolina. Position: Weld Engineering Consultant. Specialize in providing management support for the implementation of Best Weld Practices and the establishment of Weld Process Controls. At present Weld Engineering Leader (consultant) with GE Quality Council. I am providing Six Sigma manufacturing / weld / brazing process improvements to approx. 70 GE plants. In the last two years worked on USA projects for Welding Services Inc / Imperial Oil / General Dynamics / GE / Magnatech / PICO / BOA / Flexonics / GM / Dana / Textron / ABB / Tower / Milton Bridge / Manatowic Cranes / Holland Mfg / Graco Inc / Aker Ship Yard. PA. I have thirty five plus years of manufacturing / weld process control expertise. I have developed unique methods and weld training resources for the implementation of Best Weld Practices and Weld Process Controls with the MIG, GTAW, FCAW, PLASMA, LASER and SAW processes. I have advised over 1000 companies in 12 countries on methods for continuous improvement in manual and robot weld productivity, quality. My fabrication and welding expertise covers forming, manufacturing, material handling, coatings, cladding, hard facing, cutting, and welding ferrous and none ferrous, pipe, plate, structural and pressure vessel applications. During the last decade I was a key AWS committee member developing the AWS MIG Gas specifications and advisor for the AWS flux cored specifications. I am responsible for the development and introduction of four of the top 10 MIG gases used in North America. I wrote the Thermal Cutting Section” on Laser-Plasma-Oxy Fuel Cutting in the ASM Handbook Ninth Edition 1988. I wrote the complete Welding section for “Machinery Handbook” >25th edition. I have > 35 weld articles published on Weld Process Controls and Best Weld Practices and wrote three books on the subject. I developed unique MIG and flux cored training Process Control programs that have been utilized by many fortune 100 companies at also by colleges in the USA. 2. 30 plus years expertise on setting optimum MIG / FCAW manual and automated pipe / pressure vessel welds. 30 plus years expertise in establish process controls with manual / automated GTAW / PLASMA. / LASER Tube mills Turbine Repairs, Orbital welds, Micro alloy applications and automated pipe welds. Industries, nuclear, aerospace, medical, electronic, power, oil, refinery and chemical. I have 28 years expertise on establishing effective “robot” MIG weld process controls for all industries. Highly experienced in all manual and mechanized MIG / GTAW / FCAW “Cladding” applications. Provide estimates, quotes and recommendations for cost affective robot / automated weld lines and related weld manufacturing equipment. Extensive metallurgical and lab expertise on weld failures, cladding, wear and weld corrosion issues.. Work with designers to design components that are “designed to enhance weld quality & production potential. Ensure weld documentation is in compliance with ISO / ASME / API / AWS D1.1 / NACE and other welds specifications. SOME WELD ACCOMPLISHMENTS 1. Provided Robot MIG Weld Process Control Training Program for Magna the world’s largest tier one supplier. 2. Imperial / Esso Oil, Cold Lake Alberta, Canada. Requested by Imperial Oil to provide manual / automated flux cored process control training. I trained the SMAW (stick) pipe welders on the use of manual / automated flux cored and MIG on steam / natural gas / oil pipes from 10 to 100 cm diameters. The total annual weld savings generated by using flux cored with the 37-field crew was approx. $2 million annually. 3. Textron: Thailand. Managed a 6 month project and developed weld procedures and repair techniques for weld repairs on 160 Textron Stingray Army Tanks. (275.000 tensile armor plate). 4. Combustion Engineering. [1] I established unique “robot” pulsed MIG nickel weld procedures for overlay boiler walls. [2] Set robots to pulsed MIG boiler headers to pipes, (typically carried out by skilled GTAW welders). 5. Aker. Philly Naval Ship Yard. Oil Tanker Construction. Introduced to the yard Best Weld Practices and provided one day flux cored weld process control training module that within six months reduced the ship weld rework by 50%, savings, four million dollars per-ship.. 6. General Dynamics Ordinance and Tactical Systems. TX. Improved the` weld quality / productivity on 2000 bomb casings. 7. MKS Instruments, Inc. Improved their automated TIG welds on stainless and Inconel chip manufacturing monitoring devices. Attained close to 2 million dollars annual cost savings. 8. Caterpillar. Established the robot MIG weld procedures for the world’s largest robot welded trucks. 9. Ford Motor, Dearborn, MI. Requested by Ford to solve numerous robot weld issues at their Frame Plant. The implementation of my “automated weld process control program” provided Ford with the requirements to save a minimum of $500.000.00 per month in weld rework. 10. Ramco / Alcoa. Advised on robot weld issues and made dramatic improvements for GM “aluminum robot welded frames”. 11. For BOA Georgia. In three days reset Austenitic / Inconel flexible tube welds on catalytic converters. Provided “no cost” process improvement increasing the BOA weld productivity from 600,000 units per-year to 900,000 units per-year. Reduced the production weld rework from 7 to 0 % 12. GM Bowling Green KY. Established new robot, MIG weld procedures for > 99 Corvette bodies. 13. Millenium Industries. Eliminated robot / GTAW (TIG) weld process issues on Ford / Jaguar fuel injector components, saved $300,000 annually. 14. Harley Davidson. Provided robot bike frame weld procedures and weld process controls increased robot MIG weld production by 30%. 15. Chrysler Neon Cross members. Use robot / weld process expertise to provide solutions and eliminate Neon welding problems that were causing Chrysler over one million dollars a month in weld rework. 16. Hydro Aluminum. Solve GM, robot aluminum welding problems on Corvette gas trunk frames. 3. 17. Hayes Lemmerz. Large US automotive / truck wheel mfg Resolved numerous automated pulsed weld issues on both Aluminum and Steel Wheels. Produced annual savings over one million dollars. 18. Fruehauf Trailers. Resolved automated aluminum seam welds on truck floors. 19. Genie. Washington. Provided process control training and increased robot weld productivity by 30%. 20. VAW, Aluminum car seats for Ford. Solved extensive robot welding issues, increased weld production 40%. 21. Case International Tractor Div. 0ptimized the robot welds on the tractor cabs, reduced weld rework by 40% 22. Mascotech Michigan. Established robot weld process control programs for 300/400 series stainless, robot welds, 98 Ford Mustang manifolds, Chrysler Jeep and Hummer manifolds. 23. Johnson Controls Mexico. Solved robot weld productivity issues, improved weld production by 30% on new 98 VW Beetle car seats. 24. Volvo. Set up new robot weld line and provided training for Volvo Truck Cabs WV 25. Monroe Shocks. Established global uniform weld best practices and robot process controls for 5 plants. 26. Citrogen Spain. Solved robot issues. Established robot weld process controls and training for car seats. 27. Club Car. Set robot line weld data for robot welding aluminum golf carts. Present Employment Consulting Contracts. [1] Aker: Philadelphia Naval Ship Yard: Weld Mgr: Established unique Flux Cored Weld Process Control Training for oil tanker construction. The yard hass 300 welders. My eight hour training program, reduced the flux cored weld rework and NDT costs per-ship by 50%. Savings per ship approx 4 million dollars. I also established Best Weld Practices for the ship yard reducing annual weld equipment / consumable costs by $500,000. Over size, vee groove weld joints gaps on ceramic backing can typically add 300 to 400% to the cost of the ships / plate welds. I developed unique MIG / flux cored, large gap weld procedures and techniques that reduce the typical, large gap, ship weld rework cost by 60% [2] Delta (Doha) Corporation. Doha Qatar. Delta is an engineering design and manufacturing company of Wellhead Equipment & Valves. Delta is based in Doha, Qatar. I provided recommendations for automated, ID, small bore clad welding using Inconel alloys on Wellhead fittings such as tubes, adapter flanges, bonnets, studded tees, tree caps, weld neck flanges, gate valves [3] Kolberg / Astec: Rock crushing equipment, feeders, screens, sand classifying systems, aggregate conveyors, asphalt and pugmill plants. Provide weld solutions to weld cracking problems and process control (MIG FCAW) training for welders and engineers. [4] GE. Switch Gears. Transformers. Motors. Puerto Rico, Norgales Mexico. Peterborough Ont. Established Best weld Practices and Process Controls for Pulsed MIG Copper Alum applications. Provided process solutions for MIG cast steel motor housings. Provided improvements for Cu to Cu oxy fuel / inductance brazing. 4. From Jan 2006 to Jan 2007. Welding Services Inc. Atlanta. GA. Contract Position. Weld Manager. Consulting Contract. This company has provided Inconel / stainless pulsed MIG weld over lay on more than 80% of the water wall boilers in North America. WSI uses approx. one million pounds of Inconel annually. I was hired on a contract basis to develop new Stainless / Inconel clad weld procedures and techniques to reduce the Inconel weld costs and improve the weld and corrosion properties on clad applications typically found in the Power, Oil, Pulp, Waste to Energy, Nuclear, Chemical and Petrochemical industries [] WSI: My water wall new Inconel / Stainless clad procedures were patented in 2006. My new pulsed MIG procedures and techniques reduced by 28% the typical amount of Inconel or stainless cladding consumables required per-square foot of coverage of water wall boiler tubes. This patent will eventually produce an annual cost saving for WSI of approx 6 million dollars and the superior pulsed MIG over lay weld quality will provide many benefits such as longer boiler wall wear, less distortion, less weld defects. [] Provided advice and unique GTAW automated weld repair solutions for global nuclear plant weld repairs. [] Provided unique pulsed MIG pipe procedures for 9 – 36% Nickel Cryogenic applications. []Developed during 2006, a patent pending, cost effective weld technique for 347 overlay on hydro cracking vessels and other 347 clad applications. This new 347 clad method reduced the traditional global electro slag, strip clad methods cost for overlay by 70% Also in 2006 for another client I developed a new method for attaching boiler wall insulation brackets. Instead of attaching studs for the brackets, this client now used my MIG spot weld process to weld the brackets. Eliminating the studs dramatically reducing the cost of this operation. The client has patented this method. 12 month employment contact.: Company. MKS Instruments, Inc. MA. Contract Position. Weld Manager. Established Weld Best Practices and weld cost reduction programs for automated, laser / GTAW / plasma, lathe and orbital welds on stainless and Inconel components. These monitoring parts were used in the manufacture of electronic chips. Established over 2 million dollars in weld cost reduction and took weld reject rate from 8% to less than 1 percent. 2000 to 2002 Company: Textron / Omniquip. Port Washington WI. Contract Position. Weld Manager: Heavy Fab. Scope: Hired to reorganize the weld department, establish best weld practices, provide substantial weld cost reductions and increase the MIG weld automation. Responsible for approx. 120 welders. The product was heavyduty steel frames and booms used for construction lifting equipment. • In the 15 months at Textron / Omniquip, increased utilization of arc welding robots from 8% to 80%. providing an 80% increase in the welded parts produced with no increase in manual labor. • Facilitated and implemented effective robot and manual weld process controls along with weld processtraining programs, resulting in a daily robot weld efficiency of > 96% 5. • • • • Reduced the three weld vendors to one and established a “weld blanket purchase agreement resulting in $200,000 annual savings. Established highly cost effective “best weld practices”. Reducing annual equipment and consumables cost by $250,000. Produced the weld department budget. Provide support and developed the training programs for weld safety, weld quality, weld productivity. 98 - 2000 Consulting. WeldTrain. (My Consult Company) Wilmington NC: Weld Process Improvements at companies listed above. 1994 – 98 June. Company, ABB Flexible Automation Division. Two positions: [1] Corporate Quality Leader for all robot weld installations. [2] Weld Process Manager Robot Division.. [1] Hired as North American guru for ABB Customer Service Div to resolve robot weld quality / productivity issues at numerous global clients. [2] Set robot programs and provided customer advice on robot weld optimization, part and fixture design and material flow. Company, Airgas Inc. USA. 3 yrs. Position: Weld Marketing / Weld Training Manager. Airgas is the world’s largest independent welding distributor. I was employed by Mr Mc.Ausland the company owner to develop MIG weld gas / weld equipment sales strategy that would give Airgas a distinct Franchise look to its Industrial gases and welding equipment business. In eighteen months through my marketing program that simplified MIG gas selection, I introduced three gas mixes, (SteelMix – StainMix – AlumMix). With this program and the technical sales training I provided, Airgas increased it’s annual new MIG gas business by 60 million dollars. I also provided weld / cutting process training for the 700 sales reps and when requested provided weld process advice and solutions for hundreds of weld customers across USA and Canada. Note: Three multi-purpose MIG gas mixes I developed for MIG welding steels, stainless and nickel steels are now common MIG gas mixes sold throughout North America. Company AGA. Gas. Cleveland. OH. 3 yrs. Position Weld Equipment Product / Training Mgr. Same job description as Airgas. Company Union Carbide (Linde). Canada 4 yrs. Position. Weld Department Manager. Nuclear Power and Cryogenics Div. Managed the weld fabrication of heavy alloy, stainless and aluminum components used for Canada’s Cryogenic, Heavy Water and Nuclear industries. Responsible for all welding quality, productivity, weld procedures, weld qualifications, weld code compliance for more than 140 welders using GMAW- FCAW – SMAW - SAW - PLASMA – RESISTANCE. Worked with ASME, ANSI, API codes. 6. Transferred from Union Carbide to sister company Linde Weld Distribution Div as the Linde Weld Training Manger, Canadian Western Region.. Provided weld process training and advice to hundreds of customers and to Linde weld distributors. Company: Atomic Energy Nuclear Research. Ontario. Canada 4 yrs. Position: Weld Technologist. In the Nuclear research department, worked with alloy steels, stainless, aluminum and titanium pipes and tubes providing weld and cutting research. Developed new weld / repair procedures for Pickering Nuclear plant and for the Bruce Heavy water plant. Company: Weld Institute. Canada. 3 yrs: Position. Weld Research Technologist. Numerous weld research studies for major Canadian, USA corporations. Weld failures / corrosion / erosion / wear analysis for Canadian / USA companies. Shawinigan Engineering. Canada. 4 yrs. Position: Weld Quality Control Manager. For two years worked in Sapele. Nigeria. Position. Weld Quality Engineering Mgr. Responsible for welding quality during construction of Africa’s largest oil /gas power station. Provided global Inspection on US / Canadian Nuclear / power plant components, turbines, pumps, compressors, valves etc. Ontario Hydro. Canada 3 years.. Position: Quality Control Supervisor. Project: Construction of the Canadian Bruce Heavy Water / Nuclear Plant.. Experiences and Achievements: Provided GMAW / FCAW / SAW / PLASMA / GTAW / SMAW / LASER / OXY FUEL training for over 10,000 weld decision markers in ten countries. Have extensive welding application background in all major welding industries. Automotive, Ship Yards, Chemical Plants, Pipe and Pressure Vessels Shops, Structural Shops, Nuclear and Research. Optimized robot weld productivity using ABB - Motorman - Panasonic - Fanuc - ESAB Cloos, and Miller robots. Computer skills, MS Word, Word Perfect, Power Point, Web Page Management using Dream Weaver. Committees Columns, Books and Articles Published: In 1998 as an AWS specification committee member, I completed for the American Weld Society the new AWS MIG, / TIG, Plasma Welding Shielding Gas Specifications. Developed and Introduced four of biggest selling MIG gas mixes in North America. 2001 AWS subcommittee advisor on the AWS specifications for Flux Cored Electrodes. Developed the “PocketWelder” the world’s first hand size, electronic weld data / steels unit. Sold by AWS. For 15 years, I advised over 50,000 readers in the Question Answer Weld Column in Weld Design Fabrication Magazine. Published over 35 welding / cutting process control articles. Rewrote the Thermal Cutting Section” on Laser-Plasma-Oxy Fuel Cutting in the ASM Handbook Ninth Edition 1988. Wrote the complete welding section for “Machinery Handbook” >25th edition. In 1991 wrote and published welding book “Gas Metal Arc & Flux Cord Welding Parameter Selection Made Simple”, sold through AWS. In 1992 produced a MIG training video “MIG Training Made Simple” sold by AWS and Fabricator magazine. 1996 wrote the 600 page book “A Management & Engineers Guide to MIG Welding, Quality, Costs and Training”. 7 Patents Developed: 1996. Ceramic/Cu MIG gun contact tips for high speed MIG welds 98. 1997. World’s first “Portable Electronic Weld Data Unit, “Pocket Welder”. 2006 New Boiler Water Wall Clad Weld Technique. 2006 New Weld method for clad weld hydro cracking vessels. 2006. New method to weld insulation brackets to boilers. References available on request: