Scroll Saw Basics: Safety, Operation, and Fundamentals

advertisement

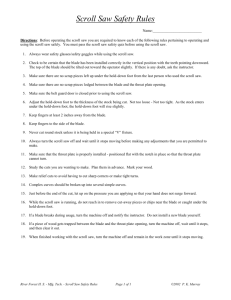

Scroll Saw General Information The scroll saw is used for cutting curved or irregular shapes. Its primary advantage over other saws is that the blade can be inserted through an opening in the work to make inside cuts. This allows for inside cuts to be made without cutting through the work. Narrow blades can also be installed to do very intricate work. These two applications make the scroll (jig) saw very useful for small, detailed work. How It Works The scroll saw uses a reciprocating (back-and-forth) cutting motion. The figure at the right shows how the motor is connected to the driving mechanism by a belt and pulley system. The drive mechanism contains a crankshaft that turns the rotary motion into a reciprocating motion. Safety Guidelines General Procedures 1. Eye protection meeting current ANSI safety standards must be worn at all times while anyone is working in the lab. 2. Never make any adjustments to a machine while it is running. 3. Never walk away while a machine is still in motion. For example, when you turn the band saw off, the blade continues to move unless the break is applied. 4. Disconnect electrical power when changing blades, bits, etc. or anytime an injury could occur if the machine is accidentally turned on. Generally this requires that the machine be unplugged or the circuit breaker turned to the off position. Scroll Saw Fundamentals: 1. Install the blade with the teeth facing down. This will hold the work down against the table. 2. Adjust and check the blade tension according to the machine manufacturer's guidelines. 3. The hold-down should be secure against the stock. Safety Quiz 1. What is the main use of a scroll saw? What makes it so good? 2. Which way is the blade put on the saw? 3. How should you have the hold-down set when using the scroll saw? 4. How does the scroll saw turn rotary motion into reciprocating motion?