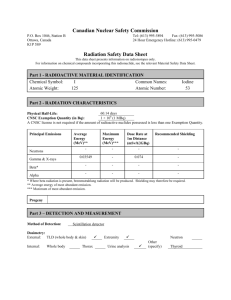

CNSC Staff Integrated Safety Assessment of Canadian Nuclear

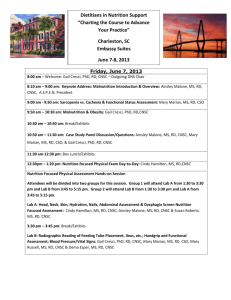

advertisement