PII:

J. stored Prod. Res. Vol. 34, No. 4, pp. 277±285, 1998

# 1998 Elsevier Science Ltd. All rights reserved

Printed in Great Britain

S0022-474X(98)00009-5

0022-474X/98 $19.00 + 0.00

The Modi®ed Count and Weigh Method: An

Improved Procedure for Assessing Weight Loss

in Stored Maize Cobs

JULIA A. F. COMPTON1*, SIAN FLOYD2, ANTHONY OFOSU1 and

BLAISE AGBO1

Ghana MoFA/UK ODA Larger Grain Borer Project, Ministry of Food

and Agriculture, P.O. Box 165, Ho, Volta Region, Ghana and 2Statistics

Section, Natural Resources Institute, Chatham Maritime, Chatham,

Kent ME4 4TB, UK

1

(Accepted 25 February 1998)

AbstractÐThis paper describes a modi®cation of the well-known count and weigh (gravimetric)

method for assessing losses due to insect pests in stored maize cobs. The modi®cation involves

counting the destroyed grains on each cob and using an adjusted calculation. Data are presented to show that the precision of the modi®ed method is similar to that of the conventional

count and weigh method. No systematic bias was detected with the modi®ed method, in contrast to the conventional method which is shown to underestimate true weight loss by up to

half. The main justi®cation given for the use of the modi®ed method is that the conventional

method underestimates loss to an unpredictable extent, depending on the degree to which pestdamaged grains retain a separate, countable identity. For example, it is shown that the degree

to which the conventional method underestimated loss was much greater for a ¯oury, smallgrained variety, in which many insect-damaged grains were reduced to powder, than for a

large-grained variety in which most damaged grains retained their identity. This implies that

comparisons of weight losses based on the conventional method should be interpreted with

great caution in studies with signi®cant amounts of destroyed grains. # 1998 Elsevier Science

Ltd. All rights reserved

Key wordsÐloss assessment, maize storage, methods, post-harvest, Prostephanus truncatus

INTRODUCTION

The count and weigh (also known as gravimetric) method is a well-known procedure for

assessing weight loss due to pest damage in stored cereals (Harris and Lindblad, 1978; Boxall,

1986). Its relative ease of use, lack of need for specialised equipment such as moisture meters,

and above all, the lack of need for a ``baseline'' (pre-storage) sample for comparison make it a

very attractive method where resources and time are scarce.

Several re®nements to the method have been published (e.g. Boxall, 1986; Ratnadass and

Fleurat-Lessard, 1991) but none has addressed the case where grain kernels are actually lost or

destroyed, as opposed to damaged, by pests. If such missing grains are not taken into account,

*Author for correspondence at Food Security Department, Natural Resources Institute, Chatham Maritime, Chatham,

Kent, ME4 4TB, UK. Fax +44 1634 880077 Email: J.A.F.Compton@greenwich.ac.uk

277

278

Julia A. F. Compton et al

the count and weigh method is likely to underestimate losses. The arrival in Africa of a new

pest of stored maize, Prostephanus truncatus Horn (Coleoptera: Bostrichidae), which reduces

many kernels to powder, highlighted this problem (Keil, 1987) and led Pantenius (1988) to

propose an alternative loss assessment method for maize cobs damaged by this pest, which

involved comparing the average weight of total grain shelled from cob samples over time.

However, for many types of research, especially on farms, it is not practicable to use the

Pantenius method (it requires a baseline sample, a moisture meter, and also large sample sizes)

and the count and weigh method continues to be widely used.

This paper describes a modi®cation to the conventional count and weigh procedure for use

with stored maize cobs, which explicitly accounts for destroyed and missing grains. It then

presents some comparative data on the accuracy and precision of the conventional and modi®ed

methods.

METHODS

The conventional count and weigh method

The conventional method is brie¯y summarised here for convenient comparison with the

modi®ed method. Full details are given in many publications, e.g. Boxall (1986).

A sample of cobs is taken from the maize store. Methods of sampling cobs from stores have

been extensively considered (Harris and Lindblad, 1978; Golob, 1981; Boxall, 1986; Nyambo,

1993) and will not be discussed in this paper since they are independent of the method used to

determine weight loss. The sampled cobs are shelled together and the resulting grains pooled.

Two subsamples of 200±500 grains each are taken using a rie divider. The grains in each

subsample are separated by eye into two groups, damaged and undamaged. Separation of

damaged from undamaged grains is discussed at length in Boxall (1986) and Ratnadass and

Fleurat-Lessard (1991). The damaged and undamaged grains in each group are then counted

and weighed.

Percentage weight loss can then be calculated separately for each subsample using

equation (1). The average of the two subsamples is taken as the weight loss for the sample of

cobs.

100 N d W u ÿ Wd N u

Nd Nu Wu

1

where

Number damaged grains in subsample = Nd

Number undamaged grains in subsample = Nu

Weight damaged grains in subsample = Wd

Weight undamaged grains in subsample = Wu

Description of the modi®ed method

The modi®ed method consists of the following eight steps:

1. A sample of maize cobs is taken as for the conventional method. We found 30 cobs to be a

convenient sample size which gave reasonably precise results.

2. The cobs are shelled one by one, and the number of destroyed and missing grains is recorded

for each cob. These are then summed over all cobs in the sample to give the total number of

destroyed and missing grains (TND). If desired, cob-related characteristics such as husk

cover and grain type can also be recorded at this point.

To assure consistency, the criteria used to de®ne ``destroyed grains'' should be clearly speci®ed

and rigorously adhered to. In our work, destroyed grains were de®ned as those which were

crushed during shelling into fragments smaller than one third of a grain, or which passed

through a 3.35 mm sieve in step 3. All such fragments must be thrown away to avoid double

counting later.

Modi®ed count and weigh method

279

3. The shelled grains from each cob are sieved through a standard sieve set (we used

3.35/2/0.85 mm mesh). If desired, the number and species of insects on each cob can be

recorded at this point.

4. The sieved grains from all the cobs are then pooled. Our typical pooled samples contain

7000±15,000 grains and weighed about 1.5±3.5 kg. The pooled sample is weighed and the weight

recorded to the nearest g. This is the Final Weight (FW).

5. A rie divider is used to subdivide the pooled sample several times to obtain two

subsamples containing about 400±600 grains each. Remaining grains are discarded. The number

of grains per subsample should be increased if there is a high proportion of damaged grains,

since it is the total number of undamaged grains which primarily determines precision (see

discussion section). A minimum of 50 undamaged grains per subsample is suggested.

6. The grains in each subsample are separated into two groups, damaged and undamaged, by

eye, in the same way as in the conventional method.

7. For each subsample, the groups of damaged and undamaged grains are counted and

weighed as in the conventional method.

Number damaged grains in subsample = Nd

Number undamaged grains in subsample = Nu

Weight damaged grains in subsample = Wd

Weight undamaged grains in subsample = Wu

8. Percentage weight loss=

100 TND

Wd Wu Wu FW

Nd Wu ÿ Nu Wd

:

TND

Wd Wu Wu FW

Nd Nu Wu

2

Weight loss is calculated separately for subsamples 1 and 2, and the average of these two values

is taken as the estimated weight loss in the cob sample.

Derivation of the weight loss equation for the modi®ed method

Equation (2) for calculating the modi®ed count and weigh loss is derived as follows:

Percentage weight loss in the sample is de®ned as

100 undamaged weight

UW ÿ final weight

FW

:

undamaged weight

UW

3

The ®nal weight in equation (3) is FW, measured in step 4 of the modi®ed procedure. The

undamaged weight (UW) in equation (3) is the estimated sample weight in the absence of grain

destruction, loss and damage. UW is not necessarily equal to the actual sample weight at the

beginning of storage, because of changes in moisture content during storage. UW is estimated

by applying the same assumptions used in the conventional count and weigh procedure, i.e.

damage is assumed to be equally allocated over large and small grains in the sample and

moisture content is assumed to be uniform over all grains in the sample. If these assumptions

are true, then the average weight of undamaged grains in the original cob sample will be equal

to the average unit weight of the remaining undamaged grains in the grain subsample, measured

in step 7, i.e. Wu/Nu. This means that the undamaged weight of the whole original cob sample

can be calculated as the product of the total number of grains estimated to be in the original

sample (TNG) and the unit weight of undamaged grain in the subsample, i.e.

UW = TNG Wu/Nu. TNG is the sum of TND, the number of destroyed and missing grains

counted in step 2, and the number of grains in the pooled sample of shelled maize. This last

parameter must also be estimated; it is obtained from the ®nal sample weight divided by the

average unit weight of (all) grain, or FW/((Wd+Wu)/(Nd+Nu)). Combining these equations

gives UW = (TND + FW(Nd+Nu)/(Wd+Wu)) Wu/Nu. Substituting for UW in equation (3)

gives equation (2).

280

Julia A. F. Compton et al

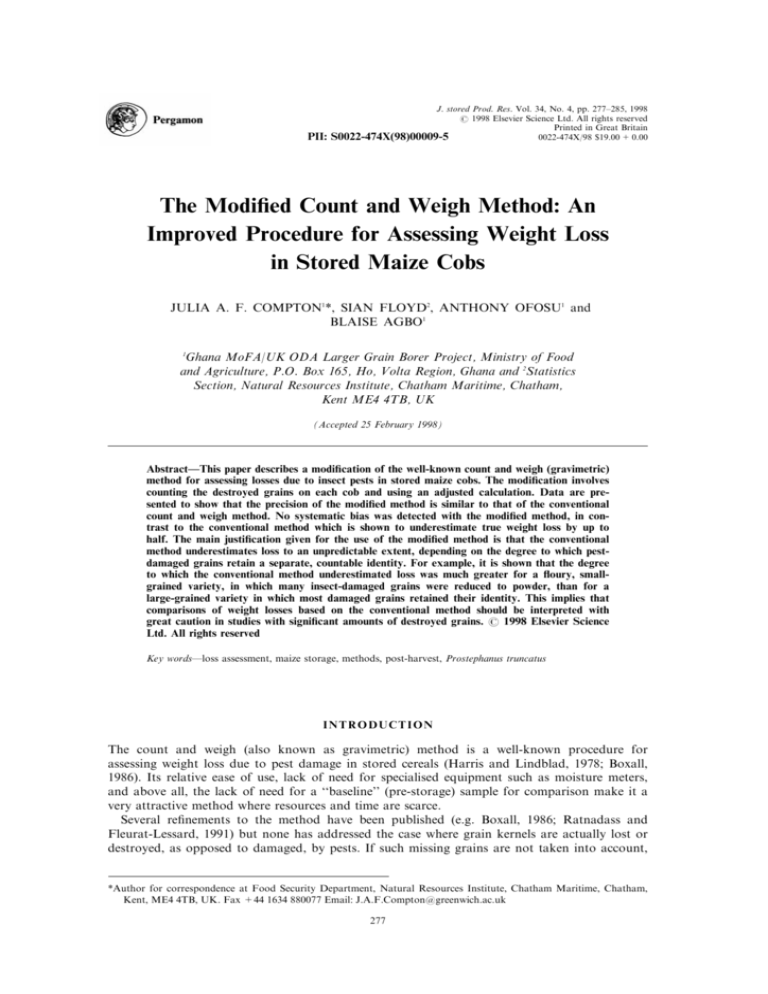

Fig. 1. Comparison of weight loss estimates obtained using conventional and modi®ed count and weigh

methods with those obtained by the method of Pantenius (1988).

Procedure used to compare traditional and modi®ed methods

Sensitivity analysis. A comparative sensitivity analysis of the conventional and the modi®ed

count and weigh methods was undertaken through spreadsheet modelling. The spreadsheet uses

as inputs simpli®ed values for variables nu, Wu, Nd, Wd, FW, and TND that are in the range of

those observed in practice, and calculates conventional and modi®ed losses for each set of input

values using equations (1) and (2). Six possible scenarios were investigated with the model: (a)

poor de®nition/count of destroyed grains (under- or over-estimation of TND); (b) poor weighing (under- or over-estimation of FW); (c) broken grain pieces double counted (higher Nd, same

Wd); (d) poor separation of subsample (Nd and Wd miscounted as Nu and Wu); (e) undamaged

grains in subsample not representative of original cob sample (under- or over-estimation of Wu);

and (f) damaged grains in subsample not representative of original cob sample (under- or overestimation of Wd). Scenarios (a)±(d) involve laboratory errors or poor practices, while (e) and

(f) might result from failure of the assumptions underlying both the conventional and the modi®ed methods. The relevant variables were changed by varying amounts and the dierences in

results using the two methods were examined.

Precision and bias. The conventional and modi®ed methods were examined for precision and

bias using several dierent batches of maize. All work was carried out in eastern Ghana.

The data in Fig. 1 and Table 2 are from a single batch composed of 15 30-cob samples of

``Fodome'', a small-grained local white maize variety taken from a maize storage trial showing

attack by P. truncatus and Sitophilus spp. Each 30-cob sample was randomly divided into three

10-cob subsamples and weight loss was measured for each using both the conventional and the

modi®ed methods. Weight loss was also measured for each 30-cob sample using the Pantenius

(1988) method as a standard of comparison: for this method the mean weight of grain per cob,

adjusted for moisture content, was compared to that of a baseline sample of 200 undamaged

cobs taken before the trial. Moisture content was measured with a calibrated capacitance meter.

All loss assessments were carried out as part of routine laboratory analysis, rather than as a

separate exercise, so that the ®gures obtained for precision would not be atypically high.

Variability between grain subsamples and between 10-cob subsamples was studied using analysis

of variance, as the distribution of the data conformed to the requirements for parametric

analysis.

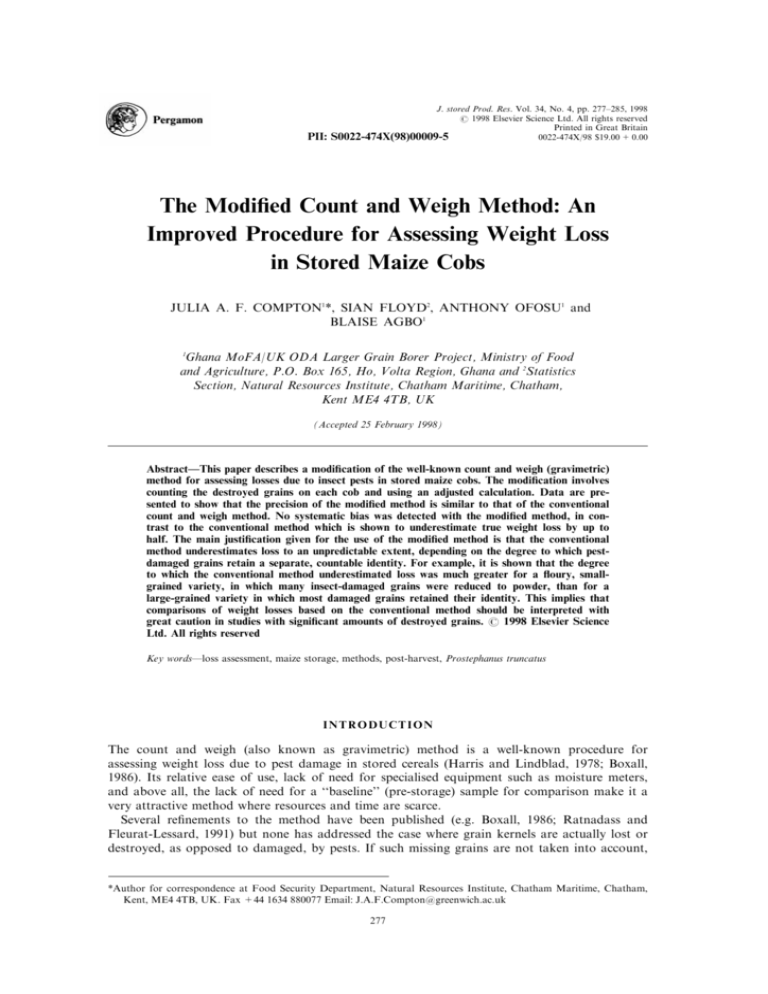

The comparison presented in Fig. 2 was taken from a dierent trial comparing weight loss

during storage in two maize varieties. These were a medium-grained, ¯inty dent high-yielding

variety (``Abeleehi'') and a small-grained, ¯oury local variety (``Kwadzeto''), both attacked by a

300

3000

3000

3000

300

300

3000

3000

3000

3000

4000

2000

3000

300

300

300

210

300

300

390

3000

FW (g)

100

100

100

100

115

100

100

100

100

100

100

Nu

100

100

70

130

108

100

100

100

100

100

100

Wu (g)

50

50

50

50

35

66

50

50

50

50

50

Nd

Subsample data

17

33

25

25

17.5

25

25

25

25

25

25

Wd (g)

C&WÐconventional count and weigh loss (equation (1) in text), ModC&WÐmodi®ed count and weigh loss (equation (2).

f2

f1

e2

e1

d

c

a2

b1

b2

a1

300

Initial

Initial scenario (simpli®ed ®gures)

Poor de®nition/count of destroyed grains

(high TND)

Poor de®nition/count of destroyed grains

(low TND)

Poor weighing (high FW)

Poor weighing (low FW)

Broken pieces double counted (higher Nd,

same Wd)

Poor separation of subsample (Nd and Wd

counted as Nu and Wu)

Undamaged grains in subsample not

representative of original cobs (high Wu)

Undamaged grains in subsample not

representative of original cobs (low Wu)

Damaged grains not representative of all

grains (high Wd)

Damaged grains not representative of all

grains (low Wd)

TND

Scenario Potential problem and variable(s) changed

Total

Wt pooled

number

grain

destr. grains sample

22.0

11.3

9.5

20.5

10.9

24.7

16.7

16.7

16.7

16.7

16.7

C&W

27.6

18.6

14.9

28.0

17.7

30.0

21.3

21.6

25.9

24.8

23.1

ÿ32

32

ÿ30

30

ÿ30

32

ÿ30

33

ÿ33

30

Ð

Percent

change in

ModC&W variable(s)

Weight loss results %

Table 1. Example results from sensitivity analysis of conventional and modi®ed count and weigh methods (spreadsheet model)

32

ÿ32

ÿ43

23

ÿ35

48

0

0

0

0

Ð

C&W

20

ÿ20

ÿ35

21

ÿ23

30

ÿ8

ÿ7

12

8

Ð

ModC&W

Percent change in weight

loss result using:

Modi®ed count and weigh method

281

282

Julia A. F. Compton et al

Table 2. Expected standard deviations of estimates of weight loss made from a single

sample of cobs, for the conventional and modi®ed methods, showing the eect of

varying sample size

Cobs per sample

10

20

30

40

50

Conventional Count & Weigh

0.057

0.043

0.037

0.033

0.031

Modi®ed Count & Weigh

0.065

0.048

0.040

0.036

0.033

pest complex dominated by P. truncatus. Weight loss was measured for each sample using both

conventional and modi®ed count and weigh methods.

RESULTS

Sensitivity analysis

Example results from the spreadsheet model, based on fairly large (c. 30%) changes in input

variables, are shown in Table 1. The only two new parameters introduced into the modi®ed

method are TND, the total number of destroyed grains (step 2) and FW, the total weight of

grains in the pooled 30-cob sample (step 4). Sensitivity analysis showed that the modi®ed

method was robust to measurement errors in these new parameters. Taking the initial scenario

shown in the table where the total number of destroyed grains (TND) = 300, and the modi®ed

count and weigh loss is 23.1%, it can be seen that a 30% increase in the count of TND to 130

(scenario (a1)) increases the modi®ed weight loss by only 1.7%, to 24.8%. (The conventional

count and weigh ®gure of 16.7% does not change, of course, since destroyed grains are ignored

in this method.) The practical conclusion is that some mistakes in counting destroyed grains can

be tolerated without too much eect on the overall result, so that rapid estimates may be

acceptable. As the counting of destroyed grains is the slowest step in the modi®ed procedure,

this may be of practical importance for its adoption on a large scale. Similarly, an increase of

33% in FW due to weighing error decreases the computed weight loss by only 1.5%, to 21.6%

Fig. 2. Comparison of weight loss results for two maize varieties (W, ¯oury Kwadzeto and w, ¯inty

Abeleehi) using conventional and modi®ed count and weigh (C&W) methods.

Modi®ed count and weigh method

283

(scenario (b1)). This implies inter alia that balances for weighing the pooled sample do not need

to be accurate beyond 1 g.

The modi®ed method, like the conventional count and weigh method, is sensitive to

measurement errors relating to the grain subsamples. These include: separation errors, of which

the most likely is the failure to identify all of the damaged grains, so that some are counted and

weighed with the undamaged portion; weighing errors; double counting of broken grain pieces

in the damaged fraction; and the possibility of the damaged or undamaged grains in the

subsample not being representative of grains in the original cobs before damage (scenarios (c)±

(f) in the table). However, it can be seen from the last two columns of the table that the

modi®ed method is less sensitive to potential errors in any of these variables than the

conventional method, due to the buering eect of the parameters associated with the destroyed

grains.

Both methods appear particularly sensitive to errors in the estimation of variable Wu, the unit

weight of undamaged grain. In the example above, underestimating Wu by 30% (scenario (e2))

leads to underestimation of the weight loss by 35% (modi®ed count and weigh) or 43%

(conventional count and weigh). Overestimating Wu (scenario (e1)) leads to slightly smaller

errors in the other direction. The subsample sizes used in the method should thus be selected to

avoid the problem, which can occur at high damage levels, of insucient numbers of

undamaged grains in a subsample leading to an atypical average weight. It is suggested that a

minimum of 50 undamaged grains be taken to give a reasonable estimate of Wu.

Data on precision and bias

Precision. The standard deviation of the weight loss estimate for a single grain subsample

taken from 10 cobs was 0.023 for the modi®ed method and 0.027 for the conventional method.

Variability between subsamples would be expected to be slightly lower for the modi®ed than for

the conventional count and weigh method, due to the buering eect of the parameters mentioned above.

The standard deviation of the weight loss estimate for a group of 10 cobs was 0.063 for the

modi®ed method and 0.054 for the conventional method. The dierence was not signi®cant at

the 5% level. The variability of weight loss between cobs would be expected to be slightly

higher for the modi®ed method than for the conventional method, since the variability

associated with the number of destroyed grains on a cob is present in addition to the variability

associated with the numbers of damaged grains.

Both the variability between grain subsamples and the variability between cob samples

contribute to overall precision. The expected precision of an estimate of weight loss made from

a single sample of cobs of the batch tested is shown in Table 2. The overall level of precision

was similar to that of other weight loss assessment methods assessed by Reed (1986). The

greater part of the variability was due to cob sampling rather than to the assessment method

itself, as also noted by Golob (1981).

A sample size of 30 cobs appears from Table 2 to represent a reasonable compromise, in onfarm work, between the need for precision and the practical limits on sampling and processing

cobs. Increasing the number of grain subsamples to three or more yielded only a very small

improvement in precision.

Bias. Figure 1 compares weight loss results obtained using the conventional and modi®ed

count and weigh methods with those obtained using the Pantenius (1988) method, which is

taken as an unbiased standard (although estimates using this method are of course also subject

to sampling error). For this batch of maize, the modi®ed count and weigh method showed a

slight tendency to underestimate losses, but this was not statistically signi®cant at the 5% level.

In contrast, the conventional count and weigh method signi®cantly underestimated losses, especially for higher levels of loss.

Figure 2 compares loss estimates given by the conventional and modi®ed count and weigh

methods for damaged samples of two maize varieties attacked by an insect complex dominated

by P. truncatus. Each point represents a single sample of 30 cobs. A linear regression line has

been ®tted for each variety, which gives a reasonable approximation over the range of data

shown. All points are below the Y = X line, showing that the computed weight loss is, as

284

Julia A. F. Compton et al

expected, consistently lower for the conventional than for the modi®ed method. The signi®cant

feature is that the regression lines for each variety have very dierent slopes (0.43 and 0.78),

implying that the conventional method has underestimated weight losses by more than half for

the ¯oury variety (``Kwadzeto'') but by only about a ®fth for the harder-grained variety

(``Abeleehi''). This is because the smaller, softer grains of the local variety crumble easily into

¯our when bored by insects and are thus missed by the conventional method, while the larger,

harder grains of the high-yielding variety mostly retain their identity when attacked. The

practical implication of this result is that using the conventional count and weigh method in a

varietal trial would lead to overestimating the performance of ¯oury, small-grained varieties

relative to harder varieties.

DISCUSSION

From the data presented here, the modi®ed count and weigh method appears to suer less

from systematic bias associated with destroyed grains than the conventional count and weigh

method, which is shown to seriously underestimate true weight loss when many grains are

destroyed by pests. However, the modi®ed method, in which cobs are shelled separately and

destroyed grains are counted, demands about 50% more labour than the conventional method

in which all the cobs in the sample are shelled together.

Is the extra investment demanded by the modi®ed method justi®ed? It might be felt that for

many purposes, absolute values of weight loss are less important than relative values, and that

in making experimental comparisons the choice of assessment method is not critical as long as it

is consistently applied. However, the data in Fig. 2 refute this, showing that the choice of

method can aect not only absolute but also relative results. In that example, which presents

comparative weight losses from a varietal trial, the conventional count and weigh method was

shown to skew results in favour of varieties in which a high proportion of insect-damaged

grains are actually destroyed, and so are missed by the conventional method.

Similar systematic biases are likely to arise in other situations where a weight loss ®gure

derived from conventional count and weigh is being used as the basis for comparison of storage

techniques. For example, the conventional method is likely to underestimate losses caused by

voracious species such as P. truncatus or rodents, where many of the grains that are attacked

are destroyed, in comparison to losses caused by species such as Sitophilus spp. or Sitotroga

cereallela Olivier, which attack many grains but destroy relatively few. Similar biases may aect

studies comparing losses in dehusked cobs compared to losses in cobs with the husk, since

attacked grains often fall o dehusked maize cobs, but are retained and counted when the husk

is present (A. Ofosu and J.A.F. Compton, unpublished data). This implies that comparisons of

weight loss data derived from the conventional method should be interpreted with great caution

in studies with signi®cant amounts of destroyed grains. This problem is also true of all other

weight loss assessment methods which make no allowance for destroyed grains, such as the

thousand-grain mass method (Proctor and Rowley, 1983), the bulk density method (Boxall,

1986) and the converted percentage damage method (Boxall, 1986; Reed, 1986).

Both the conventional and modi®ed count and weigh methods are susceptible to biases if the

assumptions underlying them are not valid (although the sensitivity analysis described above

showed the modi®ed method to be slightly less susceptible to bias than the conventional

method). This could happen, for example, where pests preferentially attack larger grains; where

mould following an insect attack increases the moisture content and thus the weight of damaged

grains; or where hidden infestation causes weight loss in apparently-sound grains. Various

changes to the conventional method have been suggested to address such potential biases: these

include separating grains into size categories by sieving before counting and weighing (Boxall,

1986), separating super®cially from severely attacked grains (Ratnadass et al., 1994) and making

a second assessment after emergence of all hidden forms of insects (Ratnadass and FleuratLessard, 1991). These could equally be applied to the modi®ed method.

The count and weigh method has proved valuable in many studies of weight loss due to pest

damage in stored cereals where other methods have proved logistically dicult (Boxall, 1986;

Ratnadass and Fleurat-Lessard, 1991). The results presented here argue strongly in favour of

Modi®ed count and weigh method

285

using the modi®ed method for any loss assessment work where destroyed grains are likely to be

signi®cant, since systematic bias is greatly reduced and precision is similar to that of the

conventional method. Furthermore, the modi®ed method is compatible with an individual cob

by cob assessment of insects and damage, which is of value in ecological studies and in studies

investigating the eect of cob-speci®c factors such as husk cover (Compton et al., 1997).

AcknowledgementsÐThis work was funded by the UK Overseas Development Administration and the Ministry of Food

and Agriculture of the Government of Ghana through the Ghana/UK Larger Grain Borer Project. Laboratory work

and data entry were carried out by many sta of the project, especially Sebastian Amekupe, Simon Kumi, Hilarius

Penni, Zenobia Motey and Rainer Krah. Many thanks also to Robin Boxall, James Compton, Chris Haines and an

anonymous referee for comments on earlier versions.

REFERENCES

Boxall R. A. (1986) A critical review of the method for assessing farm-level grain losses after harvest. Report of the

Tropical Development and Research Institute G191, viii + 139 pp.

Compton J. A. F., Addo S. and Floyd S. (1997) Varietal resistance in stored maize to the Larger Grain Borer, P.

Truncatus (Horn) In: Insects in African Economy and Environment, ed. Robertson H. G., p. 95. Proceedings of the

Joint Congress of the Entomological Society of Southern Africa and the African Association of Insect Scientists,

Stellenbosch, 30 June±4 July 1996.

Golob P. (1981) A practical assessment of food losses sustained during storage by small holder farmers in the Shire

Valley Agricultural Development Area of Malawi. Report of the Tropical Products Institute. Slough, G138. p. 32.

Harris K. L. and Lindblad C. J. (1978) Postharvest grain loss assessment methods. A manual of methods for the evaluation of postharvest losses. American Association of Cereal Chemists, Bethesda, MD, USA. p. 193.

Keil H. (1987) Losses caused by the Larger Grain Borer in farm-stored maize. In Workshop on the Containment and

Control of the Larger Grain Borer, Arusha, Tanzania, eds. G. G. M. Schulten and A. J. Toet, pp. 28±52. Tanzania

Ministry of Agriculture and Livestock Development and FAO, Typewritten.

Nyambo B. T. (1993) Post-harvest maize and sorghum grain losses in traditional and improved stores in South Nyanza

District, Kenya. International Journal of Pest Management 39, 181±187.

Pantenius C. U. (1988) Etat des pertes dans les systeÁmes de stockage due maõÈ s au niveau des petits paysans de la Region

Maritime du Togo. Report, Deutsche Gesellschaft fur Technische Zusammenarbeit (GTZ) Projekt fur

Nacherntefragen, Hamburg, Germany. viii + p. 83.

Proctor D. L. and Rowley J. Q. (1983) The thousand grain mass (TGM): a basis for better assessment of weight losses

in stored grain. Tropical Stored Products Information 45, 19±23.

Ratnadass A. and Fleurat-Lessard F. (1991) Improvement at the practical methods of assessment of losses caused by

insects in grain stored at the village level in Tropical Africa. In Proceedings of the 5th International Working

Conference on Stored Product Protection, Bordeaux, eds. F. Fleurat-Lessard and P. Ducom, pp. 1681±1691. INRA/

SPV: Bordeaux, France.

Ratnadass A., Berte S., Diarra D. and Cise B. (1994) Insect losses on sorghum stored in selected Malian villages, with

particular emphasis on varietal dierences in grain resistance. In Proceedings of the 6th International Working

Conference on Stored Product Protection, Canberra, eds. E. Highley, E. J. Wright, H. J. Banks and B. R. Champ.

CAB International: Wallingford, UK, pp. 953±959.

Reed C. (1986) Characteristics and limitations of methods to estimate losses in stored grain. Manhattan, Kansas: Kansas

State University Food and Feed Grain Institute. Special Report no. 16. iii + p. 23.