Grain boundary characterization by HRTEM, exemplified on hcp

advertisement

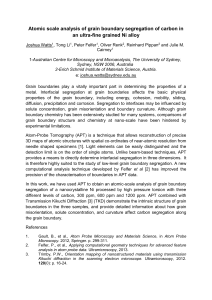

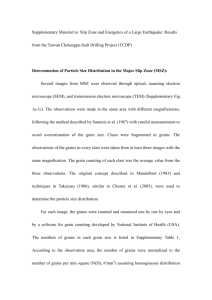

Grain boundary characterization by HRTEM, exemplified on hcp ZnO samples Ákos. K. Kiss1,2, János. L. Lábár1, Béla Pécz1 1 2 Institute for Technical Physics and Materials Science, MTA TTK MFA, Budapest, Hungary University of Pannonia, Doctoral School of Molecular-and Nanotechnologies, Veszprém, Hungary A powerful way is presented here to show high resolution characterization of grain boundaries found in multicrystalline samples. We show that substantial data can be achieved on materials with grain size of a few tens of nanometers. These investigations are based on orientation mapping which is carried out by the Astar precession/scanning tool installed on JEOL 3010 HRTEM. The new method supported by computer evaluation helps to find neighboring grains in polycrystalline materials, which can be oriented within the range of the TEM-goniometer into beneficial orientation for applying high resolution techniques on both of the grains. The tool used to obtain orientation map serves orientation data of crystalline in a large area, therefore in a short time a big amount of data is ready for the evaluation process – without such a software one could hardly find the desired experimental settings manually. By the evaluation we look for beneficial conditions for HRTEM imaging realized simultaneously in neighboring grains: in the best scenario we are able to set low index zones parallel with the electron beam resulting in simultaneous lattice resolution, while the grain boundary lies also parallel with that. Of course this kind of optimum scenario has a low chance in the case of random orientation distribution. In the other hand any of required orientation is only realized when it lies within the range of the sample holder tilt. Thus the investigations of grain boundaries are only carried out with some compromise: we get acceptable high resolution results also by orienting the neighboring grains in less optimal tilt position e. g. producing plane resolution instead of lattice resolution. The evaluation process can applied on cubic or non-cubic and one- or multi-phase systems owning to the calculation of orientations and sample tilts being based on general formalism. Examples are presented here on hcp ZnO thin film with grain size of ca. 20-40 nm deposited on Si substrate. Figure 1 shows the orientation map of the interested area. Different colors are representing different orientations (blue area at bottom: Si substrate), therefore individual grains can be recognized. The chosen boundary is marked by the white arrow. Figure 2 shows high resolution image of the observed boundary. The area marked by dashed rectangle presents no overlap; this is a good example of the investigation of interface microstructure, while the orientation-distribution is random. Figure 1. Orientation map. The observed boundary is marked by the white arrow. Figure 2. The chosen boundary shows no overlapping in the indicated area, while the neighboring grains are imaged with lattice (from [011] i.e. [-12-13] zone) and plane ((011) i.e. (01-11) planes) resolution. Acknowledgements: The authors are thankful to Edgar F. Rauch (SIMaP, Grenoble INP/CNRS, France) and Stavros Nicolopoulos (NanoMEGAS Sprl, Brussels, Belgium) for making available the Astar system. Z. Baji is acknowledged for the preparation of the ZnO layer by ALD.