Life+HEO_January 2013

advertisement

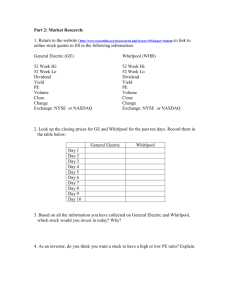

01 JANUARY 2013 newsletterproject LIFE + HEO PROJECT The aim of the LIFE HEO project is to demonstrate the feasibility of manufacturing a new class of domestic electric ovens, which allows an improved energy efficiency both in consumption at household level and during production process. It will contribute to a more sustainable development as set in the European directives on energy end-use efficiency, establishing a framework for setting the eco-design requirements for energy-using products in the home-appliances sector. The demonstrative pilot line will be implemented in existing plant in Cassinetta, Italy. PREPARATORY ACTIONS & TECHNICAL PROGRESS TEAM COMPETENCES & PROJECT MANAGEMENT The new high efficiency oven (HEO) consists of a new “ferritic” type of steel cavity with a special texture and coating that allows: The Coordination Board is made up of Project Coordinator, Financial Manager, Quality Leader and Technical Project Leader from Whirlpool and Environmental Expert from University of Manchester. A procedure of internal meetings and conference calls has been set up by the Coordination Board to ensure communication with and reporting of project progress in terms of technical and financial results. An effective follow-up is ensured through an accurate tracking of the activities, preparation of minutes and coordinating delivery of actions. A detailed project management plan has been created in order to ensure delivery of the project on time and on budget. - The Project Technical Team from Whirlpool, coordinated by the Technical Project Leader, organized bi-weekly engineering meetings to ensure an alignment on technical tasks and activities. Moreover the Technical Project Leader is scheduling a monthly conference call with Manchester University related to the environmental analysis (LCA) which will be carried out according to action C.1 “Evaluation of the Demonstration and impact monitoring”. - The Financial Manager from Whirlpool has structured the financial and administrative management of the project in order to keeping regularly the accounting on expenditures and incomes of all activities, timesheets of involved staff, invoices of suppliers. - The Dissemination Board from Whirlpool, coordinated by the Dissemination Leader, organized bi-weekly meetings to align on dissemination and communication activities. - The Coordination Board participates every two months at the monitoring meetings managed by the Project Coordinator. During these meetings, the Coordination Board evaluates if the development of the project is in line on declared target, on time and on budget according to the monitoring plan and the output indicators. INNOVATION WITH RESPECT TO THE STATE OF THE ART • • the surface to reflect more in the infrared range of the electromagnetic spectrum, thus increasing the thermal efficiency during consumers utilizations. to reduce dramatically the energy consumption in production process of about 50% per cavity, compared to the standard enamelling process. The first phase of the project “Preparation of Demonstration & Design” has been completed according to the project timetable by the end of December 2012, based on a US product geometry. A set of specific actions has been carried out in order to define energy saving targets and set down technical requirements both in terms of product design and process procedures. • • • • Target on energy saving during manufacturing has been confirmed by detailed Calculation. Product energy saving in use has been confirmed by experimental data collected Design of the demonstrative product is finalized. Design of Pilot Line is ready: Internal realization of the line is simplified by the verified possibility to used pre-coated flat sheet to be formed. Additional action plan to evaluate technology impact on European oven according to actual label regulation and its development in the next 2 to 3 years FORTHCOMING EVENTS: Whirlpool has been invited as key note speaker to present the case study of HEO as an example of mass customization applied to energy efficiency upgrade of an home appliance. The event -“Milano Mass Customization Workshop 2013”- will be in Milan on 5-6 February 2013 in Politecnico di Milano, Italy. The workshop will be a joint effort of Politecnico di Milano and RWTH University of Aachen (Germany). PARTNERS: Whirlpool Europe Whirlpool Europe SrL is a leading manufacturer and marketer of major home appliances. With 14,000 employees, a sales presence in over 30 European countries and manufacturing sites in seven countries, Whirlpool Europe is a wholly owned subsidiary of Whirlpool Corporation. Whirlpool’s European Operations’ Center is located in Comerio (VA), Italy. The company markets Whirlpool, Bauknecht, KitchenAid, Ignis, Polar, Laden in 12 Market Regions, consolidating 32 markets. Whirlpool Europe has manufacturing Centres in Sweden (Norrköping), Germany (Schorndorf), Poland (Wroclaw), Slovakia (Poprad), France (Amiens), Italy (Cassinetta, Naples, Trento) and South Africa (Ishitebe). Whirlpool Europe’s culture embracing values like sustainability, diversity and innovation is continuously seeking for better solutions for enhancing the energy efficiency of its products and innovative more sustainable technologies. In Italy, besides the managerial centre, Whirlpool Europe owns its Centre of Excellence for Research in Cassinetta, Italy, Milan district, employing more than one hundred international researchers and where the fellows will be based for carrying out the project. The Centre hosts the engineering team and two Product Development centers (1 for refrigeration and 1 for cooking products), a large Research and Engineering center with competences in the areas of Refrigeration, Electronic controls, Cooking, Washing Machines. Whirpool Europe srl - Via Aldo Moro, 5 - 21024 Cassinetta di Biadronno (Va) - tel: 0332/759111 Davide Gerola: Davide_Gerola@whirlpool.com - Gabriele Diotti - Gabriele_Diotti@whirlpool.com University of Manchester The University of Manchester is one of the top UK universities, with over 11,000 staff and 55,000 student applications each year. The University boasts no fewer than 25 Nobel Prize winners amongst its current and former staff and students. In 2010, a Nobel Prize have been awarded in Physics to two Manchester Professors. School of Chemical Engineering & Analytical Science - Room C15, The Mill The University of Manchester - Sackville Street - Manchester M13 9PL Adisa Azapagic: Adisa.Azapagic@manchester.ac.uk JANUARY 2013