Chapter 7 Attributes Control Charts

advertisement

Chapter 7

Attributes Control Charts

許湘伶

Statistical Quality Control

(D. C. Montgomery)

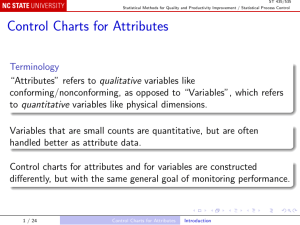

Overview I

I

Classify each item inspected: conforming or nonconforming

I

attribute variable

I

three attributes control charts:

1. p chart; control chart for fraction nonconforming (np chart)

2. c chart; control chart for nonconformities

3. u chart; control chart for nonconformities per unit

Introduction I

I

generally not as informative as variables charts

I

useful in service industries and nonmanufacturing or

transactional business process

I

not easily measured on a numerical scale

C.C. for Fraction Nonconforming I

I

fraction nonconforming: the ratio of #{nonconforming

items} in a population to the total number of items in that

population

I

The statistical principles underlying the control chart for

fraction nonconforming:

the binomial distribution

I

I

p: the probability that any unit will not conform to

specifications

the successive units produced are independent

⇒ each unit Xi ∼ Ber(p)

C.C. for Fraction Nonconforming II

I

a random sample of n units of product is selected

I

D=

Pn

i=1 Xi :

#{non conforming of units}

⇒ D ∼ B(n, p)

!

P{D = x} =

n x

p (1 − p)n−x ,

x

E(D) = np;

Var(D) = np(1 − p)

x = 0, 1, . . . , n

The sample fraction nonconforming= the ratio of the number of nonconforming units in the sample D to the sample

size n

D

p(1 − p)

⇒ p̂ =

⇒ E(p̂) = µp̂ = p; Var(p̂) = σp̂2 =

n

n

C.C. for Fraction Nonconforming III

Review:

the general model for the Shewhart control chart

I

w: statistic that measures a quality characteristic

I

µw , σw2 : the mean and variance of w

I

L: the distance of the control limits from the center

line (Customary choosing L = 3)

UCL = µw + Lσw

Center line = µw

UCL = µw − Lσw

C.C. for Fraction Nonconforming IV

I

p: the true fraction nonconforming in the production

process (a specified standard value)

Fraction Nonconforming C.C: Standard Given

s

p(1 − p)

n

s

p(1 − p)

n

UCL = µp + Lσp = p + 3

Center line = µp = p

UCL = µp − Lσp = p − 3

I

LCL < 0 ⇒ customarily set LCL = 0

⇒ assume the control chart only has an upper control

limits

C.C. for Fraction Nonconforming V

I

p is not know ⇒ estimated from observed data

I

m preliminary samples, each of size n (m : 20 ∼ 25)

I

Di : nonconforming units in sample i

I

the fraction nonconforming in the ith sample:

pi =

I

Di

,

n

i = 1, . . . , m

the average of these individual sample fractions

nonconforming:

Pm

p̄ =

(estimates p)

i=1 Di

mn

Pm

=

i=1 p̂i

m

C.C. for Fraction Nonconforming VI

Fraction Nonconforming C.C: No Standard Given

s

UCL = p̄ + 3

p̄(1 − p̄)

n

Center line = p̄

s

UCL = p̄ − 3

p̄(1 − p̄)

n

I

the trial control limits based on m initial samples

I

p̂i : to test whether the process was in control when the

preliminary data were collected

I

Phase I: Any points that exceed the trial control limits

should be investigated.

C.C. for Fraction Nonconforming VII

I

If assignable causes for these points are discovered, they

should be discarded and new trial control limits

determined.

I

If p is given ⇒ the calculation of trial control limits is

unnecessary

I

∵ p would rarely be known, we would be given a standard

value of p (represents a target value for the process)

I

If future samples indicated an out-of-control condition, we

must determine whether the process is out of control at the

target p but in control at some other value of p.

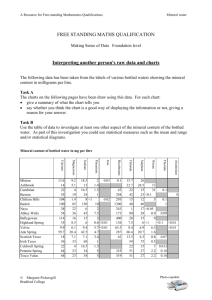

Example 7.1: cardboard cans I

Frozen orange juice

I

packed in 6 oz cardboard cans

I

determine whether it could possibly leak either on

the side seam or around the bottom joint

I

Set up a control chart to improve the fraction of

nonconforming cans produced by this machine

Example 7.1: cardboard cans II

I

m = 30 samples of n = 50 cans

I

selected at 1/2 hour intervals over a three-shift(三班制)

period

Example 7.1: cardboard cans III

Example 7.1: cardboard cans IV

Example 7.1: cardboard cans V

I

Sample 15 & 23:

investigated whether

an assignable

cause??

Example 7.1: cardboard cans VI

Example 7.1: cardboard cans VII

I

Excluding assignable

causes (Samples 15

& 23)

I

Analysis of the data

does not produce

any reasonable

assignable cause for

sample 21

⇒ decide to retain

the point

Example 7.1: cardboard cans VIII

I

If the new operator

working during the entire 2

hors period (samples 21-24)

⇒ we should discard all

four sample (21-24)

I

p̄ is much too high⇒

Engineering staff: several

adjustments can be made

on the machine

Example 7.1: cardboard cans IX

I

no assignable cause of this

out-of-control signal can be

determined

I

Test: the process fraction

nonconforming in this

current three-shift period

differs from the previous

one

H0 : p1 = p2

Example 7.1: cardboard cans X

The hypotheses:

H0 : p1 = p2

H1 : p1 > p2

P54

p̂1 = p̄ = 0.2150;

p̂2 =

i=31 Di

(50)(24)

= 0.1108

The (approximate) test statistic (p.145) :

p̂1 − p̂2

Z0 = q

= 7.10 > Z0.05 = 1.645

p̂(1 − p̂)( n11 + n12 )

p̂ =

n1 p̂1 + n2 p̂2

= 0.1669

n1 + n2

⇒ reject H0 i.e., there has been a significant decrease in the

process fallout

Example 7.1: cardboard cans XI

The new control chart:

UCL = 0.2440

Center line = p̄ = 0.1108

LCL = max{−0.0224, 0} = 0

Example 7.1: cardboard cans XII

Fraction Nonconforming Control Chart I

Three parameters in the fraction nonconforming control chart

I

the sample size (n)

I

the frequency of sampling

I

the width of the control limits

I

Common to base a control chart for fraction nonconforming

on 100% inspection of all process output over some

convenient period of time

I

I

I

a shift (一個輪班)

a day

interrelated between sample size and sampling frequency

Fraction Nonconforming Control Chart II

I

sampling frequency

1. appropriate sampling frequency for the production rate (⇒

fixes n)

2. rational subgrouping

I

Ex: three shifts-suspect shifts differ in their general quality

level

I

each shift as a subgroup;

Fraction Nonconforming Control Chart III

Sample size:

I

I

p is very small

⇒ choose n sufficiently large

⇒ a high probability of finding at least one nonconforming

unit in the sample

Otherwise, find the control limits: the presence of only one

nonconforming unit in the sample would indicate an

out-of-control condition

Ex: (p, n) = (0.01, 8) ⇒ UCL = p + 3

one nonconforming unit in the sample

⇒ p̂ = 81 = 0.1250

⇒ out of control

q

p(1−p)

n

= 0.1155

Fraction Nonconforming Control Chart IV

作法(1):

I

choose n s.t.

P(finding at least on nonconforming unit per sample) ≥ γ

I

D: #{nonconforming items in the sample}

I

Ex: p = 0.01 ⇒ P(D ≥ 1) ≥ 0.95

1. The binomial distribution:

⇔P(D = 0) =

n!

(0.01)0 (1 − 0.01)n−0 = 0.05

0!(n − 0)!

⇒n = 298

2. Using the Poisson approximation to the binomial

distribution

λ = np ≥ 3 ⇒ n = 3/p = 300

Fraction Nonconforming Control Chart V

作法(2):

I

I

Duncan (1986): choose n large enough s.t. approximately a

50% chance of detecting a process shift of some specified

amount

p0 = 0.01 ⇒ a shift to p1 = 0.05

P(detect the shigt) ≥ 0.05

r

⇔P

|p̂ − p0 | > L

⇔P

p0 − p1 − L

p

q

!

p0 (1 − p0 ) p1

n

p0 (1−p0 )

n

p1 (1 − p1 )/n

r

⇔p1 ≈ p0 + L

≥ 0.5

p0 − p1 + L

p̂ − p1

< q

<

q

p1 (1−p1 )

n

p0 (1 − p0 )

(Regard

n

p0 −p1 −L

√

q

p0 (1−p0 )

n

p1 (1−p1 )

n

√

p0 (1−p0 )/n

p1 (1−p1 )/n

≈ 0)

= 0.5

Fraction Nonconforming Control Chart VI

s

δ = p1 − p0 ⇔ δ = L

⇒n=

2

L

δ

p0 (1 − p0 )

n

p0 (1 − p0 )

⇒(p0 , δ, L) = (0.01, 0.04, 3) ⇒ n = 56

作法(3):

I

In control and p is small ⇒ choose n s.t. LCL > 0

s

LCL = p − L

p(1 − p)

(1 − p) 2

>0⇔n>

L

n

p

(p, L) = (0.05, L) ⇒ n > 171

Fraction Nonconforming Control Chart VII

I

Three-sigma control limits are usually employed on the p

chart

I

the fraction nonconforming control chart is not a

universal(通用的) model for all data on fraction

nonconforming

I

I

based on binomial distribution:

(i) p = constant

(ii) successive(連續的) unit of production are independent

nonconforming units: clustered or dependent

⇒ the fraction nonconforming control chart is often of

little use

Fraction Nonconforming Control Chart VIII

Care:

I

interpreting points that plot below the LCL

I

not represent a real improvement in process quality (ex:

caused by errors; improperly calibrated test and inspection

equipment)

The np Control Chart I

(不良品個數)

number nonconforming (np) control chart

q

UCL = np + 3 np(1 − p)

Center Line = np

q

LCL = np − 3 np(1 − p)

I

p: unavailable ⇒ p̂ = p̄

I

np chart: easier to interpret than p chart

The np Control Chart II

Example 7.2: an np control chart

I

the orange juice concentrate can process in Table 7.1

I

p̄ = 0.2313; n = 50

UCL = 20.510

Center Line = 11.565

LCL = 2.620

I

#{nonconforming units}: integer

⇒ (LCL,UCL)=(2,21)

I

if a sample value of np plotted at or beyond the

control limits

The np Control Chart III

Variable Sample Size I

I

the sample is a 100% inspection of process output over

some period of units

I

different numbers of units in each period

Three approaches to constructing and operating a control chart

with a variable n

1. Variable-width control limits

2. Control limits based on an average sample size

3. The standardized control chart

Variable Sample Size II

Variable-width control limits:

P25

Di

i=1 ni

p̄ = Pi=1

25

s

UCL = p̄ + 3σ̂p̂ = p̄ + 3

s

LCL = p̄ − 3σ̂p̂ = p̄ + 3

p̄(1 − p̄)

ni

p̄(1 − p̄)

ni

Variable Sample Size III

Variable Sample Size IV

Control limits based on an average sample size:

P25

n̄ =

i=1 ni

25

s

UCL = p̄ + 3σ̂p̂ = p̄ + 3

s

LCL = p̄ − 3σ̂p̂ = p̄ + 3

p̄(1 − p̄)

n̄

p̄(1 − p̄)

n̄

I

Assume: future sample sizes will not differ greatly

I

unusually large variation in the size of a sample or a point

plots near the approximate control limits

⇒ the exact control limits for that point should be

determined

Variable Sample Size V

Variable Sample Size VI

I

Sample 11: close to the

UCL, yet in control

I

But is using

Variable-width control

limits: it is

out-of-control

I

Care: points near the

approximate control

limits

Variable Sample Size VII

I

Problem: a change in p̂i must be interpreted relative to ni

p = 0.20 and two successive sample

p̂i = 0.28, ni = 50

p̂i+1 = 0.24, ni+1 = 250

⇒p̂i > p̂i+1 ?

0.28 − 0.2

0.24 − 0.2

∵p

= 1.41 < 1.58 = p

0.2(1 − 0.2)/50

0.2(1 − 0.2)/50

Variable Sample Size VIII

The standardized control chart:

I

the points are plotted in standard deviation units

I

Center line = 0; (UCL, LCL)=(+3,-3)

I

The variable in standardized control chart:

p̂i − p

Zi = q

p(1−p)

ni

I

I

p: the process fraction nonconforming in the in-control state

if no standard is given p̂ = p̄

Variable Sample Size IX

Minitab: Download STANDARD.mac

Variable Sample Size X

%STANDARD ’Di’ ’ni’

Variable Sample Size XI

I

difficult for operating personnel to understand and

interpret

I

the actual process fraction defective has been “lost”

OC function and ARL I

Operating-characteristic (OC) function:

I

a graphical display of the probability of incorrectly

accepting the hypothesis of statistical control (type II

error, β-error) vs. p

I

providing a measure of the sensitivity of the control

ability to detect a shift from the nominal value p̄ to

some other value p

β = P{p̂ < UCL|p} − P{p̂ ≤ LCL|p}

= P{D < nUCL|p} − P{D ≤ nLCL|p} (D ∼ B(n, p))

I

if LCL<0 ⇒ P{D ≤ nLCL|p} should be dropped

OC function and ARL II

OC function and ARL III

ARL(平均連串長度)

ARL =

1

P{sample point plots out of control}

1

α

I

In control: ARL0 =

I

Out of control: ARL1 =

1

1−β

I

p = p̄: α = 1 − β = 0.0027

1

⇒ ARL0 = 0.0027

≈ 370

I

p = 0.3: β = 0.8594

1

⇒ ARL1 = 1−0.8594

=7

I

n ↑⇒ β ↓⇒ ARL1 ↓

Control charts for defects I

I

A nonconforming item: a unit of product

I

I

I

does not satisfy one or more of the specifications of the

product

at least one nonconformity

depending on their nature and severity(嚴重): possible

contain several nonconformities and not be classified as

nonconforming

1. c chart: total number of nonconformities in a unit

2. u chart: average number of nonconformities per unit

Assume: the occurrence of nonconformities in samples of

constant size ∼ Poisson distribution

c chart I

I

defects∼ Poisson distribution

I

x: #{nonconformities}

I

c: the parameter of the Poisson distribution

I

three-sigma limits

x ∼ P(c) ⇒ p(x) =

e −c c x

,

x!

x = 0, 1, 2, . . .

c chart: Standard Given

√

UCL = c + 3 c

Center line = c

√

LCL = c − 3 c

(if obtaining nagtive LCL⇒LCL=0)

c chart II

c chart: No Standard Given (trial control limits)

√

UCL = c̄ + 3 c̄

Center line = c̄

√

LCL = c̄ − 3 c̄

c̄ = the observed average number of nonconformities in a

preliminary sample of inspection units

c chart III

Example 7.3: Printed Circuit Boards

I

26 successive sample of 100 boards

c̄ = 19.85,

√

√

(UCL, LCL) = (c̄+3 c̄, c̄−3 c̄) = (33.22, 6.48)

c chart IV

I

two points plot outside the control limits

I

exclude the two samples:

c̄ = 19.67,

(UCL, LCL) = (32.97, 6.36)

c chart V

I

#{nonconformities per board} is still unacceptably high

I

further action is necessary to improve the process

c chart VI

I

c chart is more informative than p chart

I

several different types of nonconformities

I

analyzing the nonconformities by type⇒ insight into their

cause

c chart VII

u chart I

I

the control chart on a sample size of n inspection units

(1) nc chart:

√

UCL = nc̄ + 3 nc̄

Center line = nc̄

√

LCL = nc̄ − 3 nc̄

(2) u chart: the average number of nonconformities per

inspection unit i.e., u = nx

r

UCL = ū + 3

ū

n

Center line = ū

r

LCL = ū − 3

ū

n

u chart II

Variable sample size: the number of inspection units in a

sample will not be constant

u chart III

1. Based on an average sample size: n̄ =

2. standardized statistic:

ui −ū

Zi = q

⇒ (UCL, LCL) = (+3, −3)

ū

ni

Pm

i=1 ni /m

Alternative probability models for count

data I

I

c chart: assume the Poisson distribution

I

nonconformities: cluster patterns

I

I

compound Poisson distribution

Mixtures of various types of nonconformities

Demerit Systems I

demerit(缺點) scheme:

The number of demerits in the inspection unit:

di = 100ciA + 50ciB + 10ciC + ciD

I

demerit weights for Class (A,B,C,D): (100,50,10,1)

Demerit Systems II

I

#{demeritPper unit}:

n

Di

i=1

ui = D

∼

n =

n

linear combination of independent Poisson r.v.

UCL = ū + 3σ̂u

Center line = ū

LCL = ū − 3σ̂u

whereū = 100ūA + 50ūB + 10ūC + ūD

"

(100)2 ūA + (50)2 ūB + (10)2 ūC + ūD

σ̂u =

n

#1/2

Demerit Systems III

OC curve of u chart:

β = P{x < UCL|u} − P{x ≤ LCL|u}

= P{c < nUCL|u} − P{cx ≤ nLCL|u}

= P{nLCL ≤ x < nUCL|u}

dn UCLe

=

X

x=<n LCL>

e −nu (nu)x

x!

Attributes and Variables Control Chart I

I

Variables control chart: x̄ and R charts, x̄ and s charts

I

I

I

I

more information about process performance

process mean and variability might be obtained

provide relative to the potential cause of that out-of-control

signal

indication of impending(即將發生的) trouble and allow to

take corrective action before any defectives are actually

produced

Attributes and Variables Control Chart II

I

Attributes control chart: p (np) chart, c chart, u chart

I

I

I

several quality characteristics can be considered jointly

sometimes avoiding expensive(昂貴的) and

time-consuming(費時的) measurements

Generally, variables C.C. are preferable to attributes

Attributes and Variables Control Chart III

Example 7.7: Advantage of Variables C.C.

I Nominal value of the mean and std: (µ, σ) = (50, 2)

I SL (±3-σ): (USL,LSL)=(56,44)

I x̄ chart: the process is in control at the nominal level of µ0 50,

p0 = 0.0027

I Suppose: µ0 = 50 → µ1 = 52; p0 = 0.0027 → p1 = 0.0228;

β = 0.50

i.e., P{detecting this shift on the first subsequent sample} = 0.50

I Appropriate n for x̄ chart and comparing it to the n for a p

chart?

Attributes and Variables Control Chart IV

3(2)

UCL of x̄ chart: 50 + √ = 52 ⇒ n = 9

n

β-error of p chart: n =

2

L

δ

p0 (1 − p0 ) = 59.98∼

= 60

Attributes and Variables Control Chart V

Example 7.8: Misaaplication of x̄ and R charts

I

inspected a sample of the production units several

times each shift using attributes inspection

I

p̂i : estimate of the process fraction nonconforming

I

A consultant: converting their fraction

nonconforming data into x̄ and R charts;

each group of 5 successive values of p̂i

5

1X

x̄ =

p̂i ;

5 i=1

R = max(p̂i ) − min(p̂i )

Attributes and Variables Control Chart VI

Attributes and Variables Control Chart VII

Guidelines for Implementing C.C. I

Some general guidelines helpful in implementing control chart:

I

Determining which process characteristics to control

I

Determining where the charts should be implemented in

the process

I

Choosing the proper type of control charts

I

Taking actions to improve processes as the results of

SPC/control chart analysis

I

Selecting data-collection systems and computer software