Attribut

advertisement

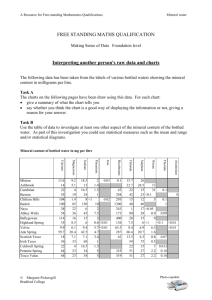

Control Chart Selection 3 Quality Characteristic variable attribute defective n>1? no x and MR yes n>=10 or no computer? yes x and s defect x and R constant sample size? yes no p-chart with variable sample size constant sampling unit? p or np yes no c u Comparison of Variables v. Attributes Variables Fit certain cases. Both mean and variation information. More expensive? Identify mean shifts sooner before large number nonconforming. Attributes Fit certain cases – taste, color, etc. Larger sample sizes. Provides summary level performance. Must define nonconformity. Types of Control Control Chart Attribute control charts Monitors p chart Process fraction defective c chart number of defects u chart defects per unit Variables control charts X-bar chart Process mean R chart (Range Chart) Process variability When are Shifts Detected ? Lower Upper Specification Limit Process Target Specification Limit LCL UCL Nonconformity Control Chart Identifies Mean Shift Here Attribute Chart Identifies Mean Shift Here Variables v. Attributes Both have advantages. At High levels - Attribute charts, identify problem areas. At Lower levels – Variables charts, quantitative problem solving tools. Ch 12- Control Charts for Attributes p chart – fraction defective np chart – number defective c, u charts – number of defects Defect vs. Defective ‘Defect’ – a single nonconforming quality characteristic. ‘Defective’ – items having one or more defects. Legal Concerns with Term ‘Defect’ Often called ‘nonconformity’. Possible Legal Dialog Does your company make a lot of ‘defects’? Enough to track them on a chart ? If they are not ‘bad’, why do you call them ‘defects’, sounds bad to me. So you knowingly track and ship products with ‘defects’? Summary of Control Chart Types and Limits Table 12.3 These are again ‘3 sigma’ control limits p, np - Chart P is fraction nonconforming. np is total nonconforming. Charts based on Binomial distribution. Sample size must be large enough (example p=2%) Definition of a nonconformity. Probability the same from item to item. c, u - Charts c and u charts deal with nonconformities. c Chart – total number of nonconformities. u Chart – nonconformities per unit. Charts based on Poisson distribution. Sample size, constant probabilities. How to Interpret Attribute Charts Points beyond limits- primary test. Below lower limits means process has improved. Zone rules do not apply. Rules for trends, shifts do apply. Only get One Chart !! Examples of When to Use p,np charts– Number of nonconforming cables is found for 20 samples of size 100. Number of nonconforming floppy disks is found for samples of 200 for 25 trials. c,u charts Number of paint blemishes on auto body observed for 30 samples. Number of imperfections in bond paper – by area inspected and number of imperfections. p-chart Jika bohlam tidak menyala, lampu yang rusak Perusahaan ingin Perkirakan persentase bohlam rusak dan Tentukan apakah persentase bohlam rusak terus meningkat dari waktu ke waktu.. Sebuah peta kendali p adalah alat yang sesuai untuk menyediakan perusahaan dengan informasi ini. Notation Sample size = n = 100 Number of samples (subgroups) = k = 5 X = number of defective bulbs in a sample p = sample fraction defective = ??? p-bar = estimated process fraction defective P = process fraction defective (unknown) p-bar is an estimate of P Inspection Results Day 1 2 3 4 5 n 100 100 100 100 100 X 20 5 30 35 24 Compute p and p-bar Day 1 2 3 4 5 Sum p-bar n 100 100 100 100 100 X 20 5 30 35 24 p=X/n 0.20 0.05 0.30 0.35 0.24 1.14 0.23 p-bar (Estimated Process Fraction Defective) p p - bar p k p 1.14 p 0.23 k 5 p-Chart Control Limits p (1 p ) UCL p 3 n p (1 p ) LCL p 3 n p-Chart - Control Limits .23(1 .23) UCL .23 3 .356 100 .23(1 .23) LCL .23 3 .104 100 p-Chart for Bulbs 0.4 p 0.3 LCL UCL 0.2 p-bar p 0.1 0 1 2 3 Day 4 5 Interpretation The estimated fraction of defective bulbs produced is .23. On Day 2, p was below the LCL. This means that a special cause occurred on that day to cause the process to go out of control. The special cause shifted the process fraction defective downward. This special cause was therefore favorable and should be ??? Interpretation After Day 2, the special cause lost its impact because on Day 4, the process appears to be back in control and at old fraction defective of .23. Until the special cause is identified and made part of the process, the process will be unstable and unpredictable. It is therefore impossible to obtain a statistical valid estimate of the process fraction defective because it can change from day to day. Trend Within Control Limits Process fractions defective is shifting (trending) upward P Sampling Distribution P UCL p-Chart LC L P P P = process fraction defective Applications Think of an application of a p-chart in: Sales Shipping Law department Use of c-Charts When we are interested in monitoring number of defects on a given unit of product or service. Scratches, chips, dents on an airplane wing Errors on an invoice Pot holes on a 5-mile section of highway Complaints received per day Opportunity for a defect must be infinite. Probability of a defect on any one location or any one point in time must be small. c-Chart c-chart c = number of defects notation: k = number of samples c - bar c estimated mean number of defects c-Chart A car company wants to monitor the number of paint defects on a certain new model of one of its cars. • Each day one car in inspected. • The results after 5 days are shown on the next slide. c-Chart Day 1 2 3 4 5 Sum c c-bar c 5 2 8 7 11 33 6.60 c-bar 6.6 6.6 6.6 6.6 6.6 LCL 0 0 0 0 0 UCL 14.307 14.307 14.307 14.307 14.307 c-Chart - Mean c c k c 33 c 6.6 k 5 c-Chart – Control Limits LCL c 3 c UCL c 3 c c-Chart – Control Limits LCL c 3 c 6 .6 3 6 .6 1.107 or 0 UCL c 3 c 6 .6 3 6 .6 14.307 c-Chart for Number of Paint Defects c, number of defects 16 14 12 c 10 LCL 8 UCL 6 c-bar 4 2 0 1 2 3 Car 4 5 Conclusion Process shows upward trend. Even though trend is within the control limits, the process is out of control. Mean is shifting upward This is due to an unfavorable special cause. Must identify special cause and eliminate it from process. Who is responsible for finding and eliminating special cause? Mini Case Think of an application of a c-chart bank. u-Chart With a c chart, the sample size is one unit. A u-chart is like a c-chart, except that the sample size is greater than one unit. As a result, a u-chart tracks the number of defects per unit. A c-chart monitors the number of defects on one unit. u-Chart A car company monitors the number of paint defects per car by taking a sample of 5 cars each day over the next 6 days. The results are shown on next side. u-Chart Day 1 2 3 4 5 6 Sum u u-bar n 5 5 5 5 5 5 c 45 58 48 53 68 44 u=c/n 9.0 11.6 9.6 10.6 13.6 8.8 63.2 10.5 u-bar 10.5 10.5 10.5 10.5 10.5 10.5 LCL 6.18 6.18 6.18 6.18 6.18 6.18 UCL 14.888 14.888 14.888 14.888 14.888 14.888 u-Chart u u k u 63.2 u 10.5 k 6 u-Chart u LCL u 3 n u UCL u 3 n u-Chart u LCL u 3 n 10.5 10.5 3 6.18 5 u UCL u 3 n 10.5 10.5 3 14.89 5 u-Chart u-Chart c, number of defects Number of Paint Defects Per Car 16 14 12 LCL 10 UCL 8 6 u u-bar 4 2 0 1 2 3 4 Car 5 6 Conclusion The process appears stable. We can therefore get a statistically valid estimate the process mean number of defects per car. Our estimate of the mean number of paint defects per car is 10.5, the center line on the control chart. Thus, we expect each car to have, on average, 10.5 paint defects. Conclusion Although the process is stable, the number of defects per car is too high. Deming calls this a stable process for the production of defective product. Important take away: A stable process (process in control) is not necessarily a good process because it can be in control at the wrong level. A stable process is predictable, but this doesn’t mean that what is being predicted is favorable. Mini Case Who is responsible for improving this process? What is required to improve the process? u-Chart vs. c-Chart c u n If n = 1, u = c and u c . Control limits of the two chart will therefore be the same. Sample Size Control Chart When To Use Sample Size p-Chart Monitor the proportion of defectives in a process At least 50 c-Chart Monitor the number of defects 1 u-chart Monitor the number of defects per unit >1 In Practice You need 25 to 30 samples before computing initial control limits. When a special cause occurs, you should eliminate that sample and re-compute control limits if Special cause is identified Eliminated or made part of process To identify special causes, workers must keep log sheet, where they record any changes they make to the process. Tracking Improvements UCL UCL LCL LCL Process centered Process not centered and stable and not stable UCL LCL Additional improvements made to the process Sampel SAMA…p chart • Proporsi diketahui p p 3 p • Garis TengahUCL = p¯ LCL p p 3 p p p( 1 p ) n • ProporsiSampel TIDAK SAMA…p diketahui chart m nomer sampel (vertikal) n ukuran sampel (horisontal) D bagian tidak sesuai p¯ = ∑Di/(mn) Garis Tengah = p¯ UCL p p 3 p LCL p p 3 p p p( 1 p ) n Sampel BEDA … a. Metode INDIVIDU Batas Kendali tergantung ukuran sample tertentu shg BKA/BKB tidak berupa garis LURUS b. Metode RATA_RATA Ukuran sampel RATA RATA dg perbedaan tidak terlalu besar ( n¯ = ∑n/observasi) c. Peta Kendali TERSTANDAR dg GT=0 dan BK ± 3 np Chart UCL = np 3 np( 1 p) LCL = np 3 np(1 p) assuming: np > 5 n(1-p) > 5 Note: If computed LCL is negative, set LCL = 0 c-chart dan u-chart Mengetahui banyaknya kesalahan unit produk sbg sampel Sampel konstan c-chart Sampel bervariasi u-chart Aplikasi : bercak pd tembok, gelembung udara pd gelas, kesalahan pemasangan sekrup pd mobil C - chart Number of defects per unit: c¯ = ∑ ci / n c c UCLc c 3 c LCLc c 3 c U-chart u¯ = ∑ ci/n n ¯ = ∑ ni/g g = banyaknya observasi Model Individu BPA-u = u¯ + 3 √ (u¯ /ni) BPB-u = u¯ - 3 √ (u¯ /ni) Model Rata-rata BPA-u = u¯ + 3 √ (u¯ /n¯) BPB-u = u¯ - 3 √ (u¯ /n¯) Warning Conditions….. Western Electric : 1. 1 titik diluar batas kendali ( 3σ) 2. 2 dr 3 titik berurutan diluar batas kend64li (2σ) 3. 4 dr 5 titik berurutan jauh dari GT (1σ) 4. 8 titik berurutan di satu sisi GT 5. Giliran panjang 7-8 titik 6. 1/beberapa titik dekat satu batas kendali 7. Pola data TAK RANDOM Patterns to Look for in Control Charts Example………p-np chart Twenty samples, each consisting of 250 checks, The number of defective checks found in the 20 samples are listed below. (proporsi tidak diketahui) 4 2 1 8 5 5 3 3 2 6 7 4 4 2 5 5 2 3 3 6 Control Limits For a p Chart Estimated p = 80/((20)(250)) = 80/5000 = .016 p(1 p) .016(1 .016) .015744 p .007936 n 250 250 UCL = p 3 p .016 3(.007936) .039808 LCL = p 3 p .016 3(.007936) -.007808 0 Note that the computed LCL is negative. Tdk sesuai Proporsi Tdk sesuai Proporsi 4 (4/250) = 0,016 2 (2/250) = 0,008 1 (1/250) =0,004 8 (8/250) = 0,032 5 5 3 3 2 6 7 4 4 2 5 5 2 3 3 6 Control Limits For a p Chart p Chart for Norwest Bank 0.045 Sample Proportion p 0.040 UCL 0.035 0.030 0.025 0.020 0.015 0.010 0.005 LCL 0.000 0 5 10 Sample Number 15 20 Ukuran sampel sama = 50 ( p-chart) no Banyak produk cacat no Banyak produk cacat 1 4 11 3 2 2 12 5 3 5 13 5 4 3 14 2 5 2 15 3 6 1 16 2 7 3 17 4 8 2 18 10 9 5 19 4 10 4 20 3 n = m = D = p¯ = BKA = BKB = Tabel proporsi untuk plot ke grafik n = 50 m = 20 D = 72 p¯ = 72 / (20.50) = .072 p = √ (0,072)(0,928)/50 = .037 BKA = 0,072 + 3(0,037) = 0,183 BKB = 0,072 - 3(0,037) = -0,039 = 0 Tabel proporsi untuk plot ke grafik Ukuran sampel sama = 50 ( p-chart) cacat proporsi cacat 4 (4/50 ) = 0,08 3 2 (2/50) = 0,04 5 proporsi (5/50) = 0,01 5 5 3 2 2 3 1 2 3 4 (10/50) = 0,20 (out) revisi 2 10 (4/50) = 0,08 5 4 (3/50) = 0,06 4 3 Revisi p¯ = (72-10) / (1000-50) = 62/950 = 0,065 p = √ (0,065)(0,935)/50 = 0,035 BKA = 0,065 + 3 (0,035) = 0.17 BKB = 0,065 - 3 (0,035) = -0,04 = 0 Grafiknya juga berubah Ukuran sampel beda (p chart) no sampel Produk cacat no sampel Produk cacat 1 200 14 11 190 15 2 180 10 12 380 26 3 200 17 13 200 10 4 120 8 14 210 14 5 300 20 15 390 24 6 250 18 16 120 15 7 400 25 17 190 18 8 180 20 18 380 19 9 210 30 19 200 11 10 380 15 20 180 12 Jml sampel 4860 Jml Cacat 341 Metode Rata-rata Sampel rata-rata n¯ = total sampel /observasi = 4860/20 = 243 p¯ = D/(n¯m) = 341 / (243.20) = 0,07 (CL) p = √ (0,07(0,93))/243 = 0,0164 BPAp = 0,07 + 3 (0,0164) = 0,119 BPBp = 0,07 - 3 (0,0164) = 0,021 Metode Individu Sampel rata-rata n¯ = total sampel /observasi = 4860/20 = 243 p ¯ = D/(n¯m) = 341 / (243.20) = 0,07 (CL) semua titik sama BP (obs-1) p = √ (0,07(0,93))/200 = 0,018 BPA = 0,07 + 3 (0,018) = 0,124 BPB = 0,07 - 3 (0,018) = 0,016……………….dst Tabel Proporsi untuk Grafik No observasi sampel cacat proporsi 1 200 14 0,070 2 180 10 0,055 3 200 17 0,085 4 120 8 0,067 5 300 20 … 6 250 18 … 7 400 25 … 8 180 20 … 9 210 30 … 10 380 15 … 11 190 15 … 12 380 26 … 13 200 10 … 14 210 14 … 15 390 24 … 16 120 15 … 17 190 18 0,095 18 380 19 0,050 19 200 11 0,055 20 180 12 0,067 Example…c-chart no Byknya kesalahan no Byknya kesalahan 1 5 11 9 2 4 12 7 3 7 13 8 4 6 14 11 5 8 15 9 6 5 16 5 7 6 17 7 8 5 18 6 9 16 19 10 10 10 20 8 c¯ = ∑c/n = 152/20 = 7,6 BPA c = (7, 6) + 3 (√7,6) = 15,87 BPB c = (7, 6) - 3 (√7,6) = -0,67 = 0 Example…u-chart no Sampel cacat no sampel cacat 1 20 5 11 30 9 2 30 14 12 25 16 3 25 8 13 25 12 4 15 8 14 25 10 5 25 12 15 10 6 6 10 6 16 20 8 7 20 20 17 20 5 8 15 10 18 10 5 9 15 6 19 30 14 10 25 10 20 20 8 Metode Rata-rata Sampel Rata-rata u¯ = 192/415 = 0,462 (CL) n¯ = 415/20 = 20,75 BPAu = (0,462) + 3 √ (0,462/20,75) = 0,906 BPBu = (0,462) - 3 √ (0,462/20,75) = 0,018 Metode Individu Sampel Rata-rata u¯ = 192/415 = 0,462 (CL) n¯ = 415/20 = 20,75 Batas Kendali Observasi -1 BPA-1 = (0,462) + 3 √ (0,462/20) = 0,916 BPB-1 = (0,462) - 3 √ (0,462/20) = 0,008…….dst