Building with the

Site-cast Concrete System

Factory methods at the job site provide a smooth

flow of men and materials when carefully planned

BY C.E. WARNES, REGIONAL MANAGER,

INTERNATIONAL ENGINEERING COMPANY, INC.

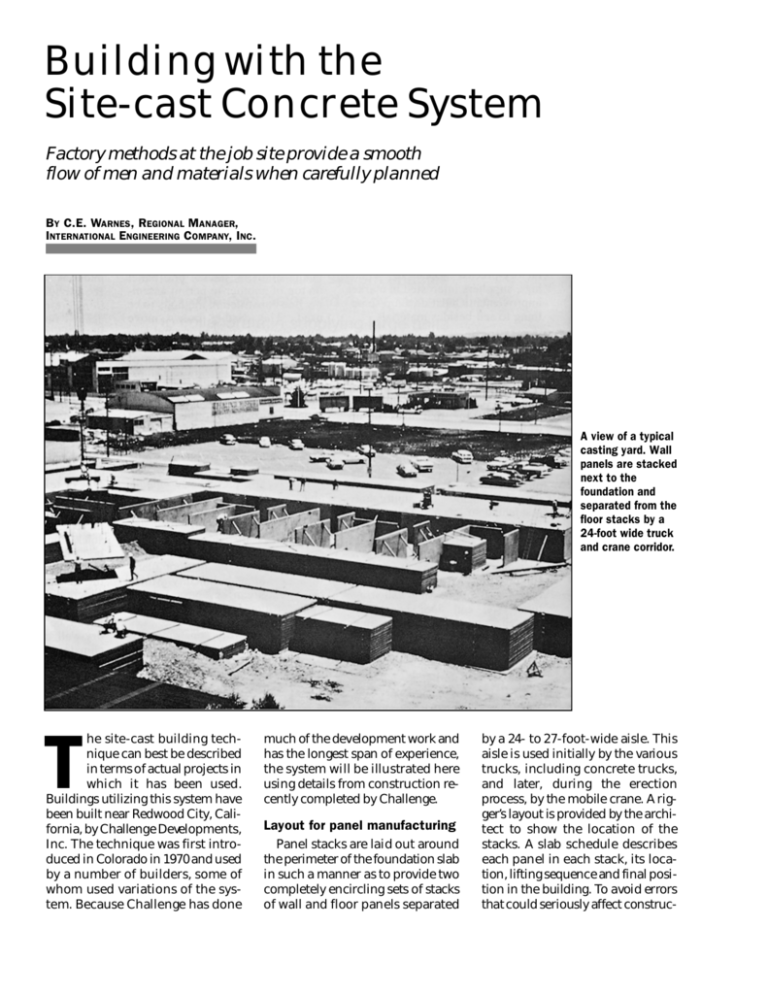

A view of a typical

casting yard. Wall

panels are stacked

next to the

foundation and

separated from the

floor stacks by a

24-foot wide truck

and crane corridor.

he site-cast building technique can best be described

in terms of actual projects in

which it has been used.

Buildings utilizing this system have

been built near Redwood City, California, by Challenge Developments,

Inc. The technique was first introduced in Colorado in 1970 and used

by a number of builders, some of

whom used variations of the system. Because Challenge has done

T

much of the development work and

has the longest span of experience,

the system will be illustrated here

using details from construction recently completed by Challenge.

Layout for panel manufacturing

Panel stacks are laid out around

the perimeter of the foundation slab

in such a manner as to provide two

completely encircling sets of stacks

of wall and floor panels separated

by a 24- to 27-foot-wide aisle. This

aisle is used initially by the va ri o u s

t ru c k s, including concrete trucks,

and later, during the erection

process, by the mobile crane. A rigger’s layout is provided by the architect to show the location of the

stacks. A slab schedule describes

each panel in each stack, its location, lifting sequence and final position in the building. To avoid errors

that could seriously affect construc-

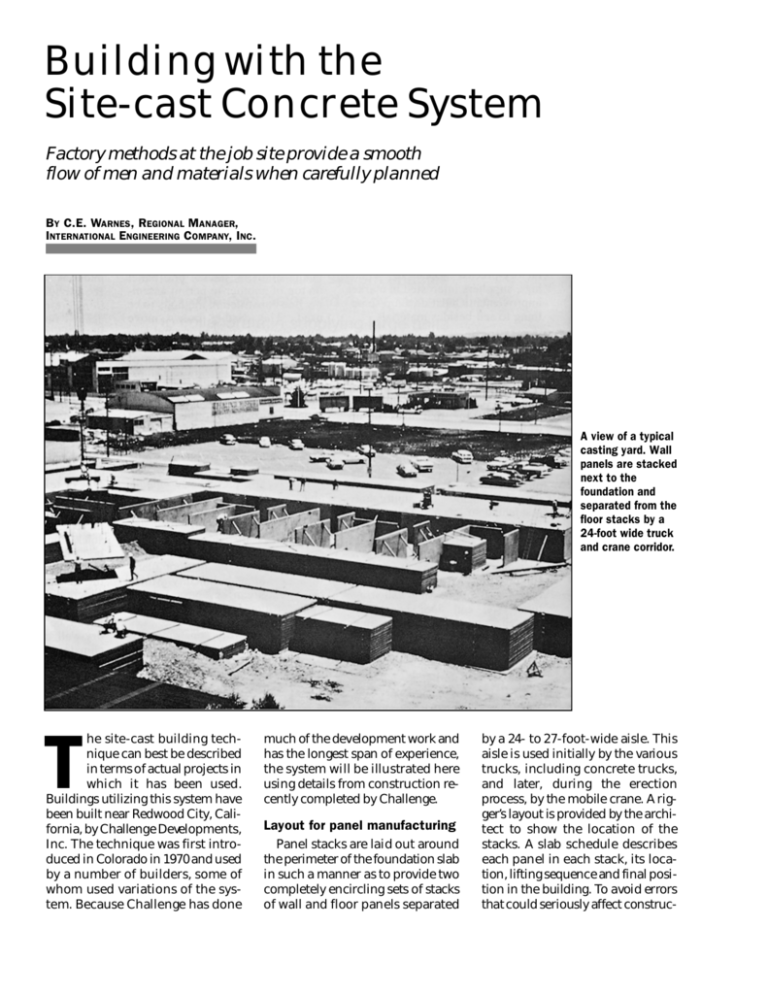

Large wall panel being

lowered into place. A

typical setting cycle

of three to five

minutes for each wall

panel is the target.

tion costs, every panel is detailed in

shop drawings and field-checked by

a representative of the architect.

Each wall and floor panel is detailed separately and assigned an

identifying number relating both to

its position in the building and to its

floor level. Walls are identified by

the letter W and floors by S for slab.

Scheduling all the panels to face in

the same direction prevents reversal

of panels during lifting. An improperly fabricated or located panel can

be very costly.

Casting beds

Thin concrete casting beds are

carefully laid out and placed to provide a foundation on which subsequent panels can be fabricated.

Panels are cast one on top of another, with as many as fourteen to sixteen in a stack. The panels to be lifted last are cast first, a necessity if

unnecessary movement of panels is

to be avoided. At first concrete may

be deposited directly from ready

mix trucks, but when the height of

the stack reaches approximately five

feet a pump is used to lift the concrete to the desired height. Panels

are designed as large as possible

consistent with architectural requirements and the capability of the

erection crane.

cians, one plumber and three steel

w o rk e r s. Concrete work is subcontracted. Approximately 7,000 to

8,000 square feet of panels are

formed and cast daily.

A production schedule that permits the placement of a full lift of

concrete each day is established.

The forms for each successive

placement are held by brackets fastened to the previously placed panel by means of snap ties cast in the

panel. After the forms are set they

are checked for dimensional accuracy. Each panel has its own shop

drawing which shows the location

of special installations such as

blackouts and electrical conduits.

These locations are marked in chalk

or crayon on the surface of the pre-

viously placed

panel. Anchor devices and lifting

anchors are then installed, followed

by reinforcing steel which is placed

using a combination of welded

mesh and reinforcing bars. Electricians install prefabricated conduits

and outlets at this time. Foamed

polystyrene blocks are placed as required to provide voids for mechanical and electrical connections that

will be made after the panels are in

place in the building.

Constant inspection is re q u i re d

during this period. The stru c t u ra l

engineer certifies a member of the

architect’s staff to the building department, which then accepts his

reports in place of its own inspections. Before concrete is placed the

Panel details

A typical crew consists of thirteen

carpenters, five laborers, six electri-

Wood bracket used to support wood sideforms is held by a metal tie

cast in a previous panel.

architect’s representative, who is on

the job full time during this phase

of construction, checks each panel

for accuracy.

Casting

Concrete is placed conventionally

and vibrated in a flat position in the

same manner as it would be for a

sidewalk or a floor. The finish is

powe r- t roweled and then touched

up by hand.

Curing

A chlorinated-rubber curing

compound is applied immediately

after troweling. As soon as it dries, a

bond breaker is sprayed on. Extreme care must be exercised in selecting the type of bond breaker and

in adhering strictly to the manufacturer’s directions during its application. Both operations— curing and

bond breaking—are handled

through a bonded subcontractor

who guarantees panel separation.

The top layer of panels is normally

cured seven days, or to a strength of

2,000 psi, before the panels are lifted. This waiting period may be reduced somewhat by using extra cement, high early strength cement,

a c c e l e ra t o r s, or other methods of

accelerating strength gain.

Erection stage of construction

The key to erection efficiency is

preplanning. A crane modified to

provide 100-ton capacity is used.

The California builder has suggested that additional economies might

result from use of an even larger

c ra n e, primarily because it would

decrease the number of moves by

increasing the reach. The crane

moves around the structure in the

corridor provided between rows of

stacks, setting wall panels and floor

slabs for each story.

Setting wall panels

Braces are bolted to threaded

studs which are shot into the wall

panels by powder-actuated guns

while the panels are still on the

ground. The lifting rings are bolted

to cast-in-place inserts in the top

edge of the wall panels. Meanwhile,

Prefabricated conduit

sections are installed in

wall and floor panels.

the open spaces between the floor

slabs are overfilled with a layer of expansive grout so that the grout will

be squeezed into grout keys in the

wall edges when the panels are set

into place.

The panels are guided into place

against wood blocks or metal angles

previously fastened to the floor with

concrete nails. As soon as the bottom of a panel is properly located,

the bottom ends of the braces are

fastened to the floor, again to powder-driven threaded shanks, and the

crane is released to go back for another load. The walls are then

plumbed by screws on the braces. A

typical cycle as outlined above takes

three to five minutes.

ing used except that a single continuous bar extends through all the

floors, connecting to a similar bar

extending from the foundation. Lateral shear transverse to the length of

the wall panel is carried by a grouted

keyway in the top and bottom of

each wall panel.

Floor connections

The two and one-half-inch openings between slabs are spanned by

welding straps (rebar) to bars previously embedded in each floor slab.

The openings are filled with expansive grout at the same time grout is

laid for the base of the wall panels.

This makes the floor act as a large

horizontal diaphragm.

Setting floor slabs

Floor slabs, being larger than wall

panels, generally take longer to set

in place. Lifting devices are provided

in the top surfaces of the floor slab

so they can be lifted in a horizontal

position. A special rigging frame is

used to distribute the lifting stresses.

Panel connections

Se ve ral connection details have

been tried. In earlier buildings steel

tie-down plates extending through

the floor and welded to anchor

plates at the top and bottom of wall

panel ends were used. In another

case oval tubes were cast in the ends

of each wall panel for which a connection was specified. Overlapping

reinforcing bars three stories high

were inserted into the tubes from

above, lowered through the floors

into a tube in the foundation slab

and then grouted in place. Currently the same general concept is be-

Several wall connection methods can

be used. This one involves a

continuous reinforcing bar that is

passed through metal tubes in the

walls all the way to the foundation

and grouted into place.

Construction rate

The construction cycle for buildings constructed using the site-cast

technique can be quite attractive to

investors. The relatively large buildings described here required nine

months from ground breaking to

completed building ready for

move-in. This rapid construction

time is achieved mainly by the use

of industrialized assembly line

methods made possible by repetitive activities.

The speed possible with this technique is illustrated by the 85 wall

panels erected in a single eight-hour

day on the Broadway II Project, an

a ve rage of one every six and onehalf minutes. Since floor slabs take

longer to put in place the maximum

number that has been set in one day

is 53, an average of one every nine

minutes. However, records are being

broken with each new building as

p ro c e d u res and techniques are refined. The following table provides

some of the production details on

three Challenge projects.

Speed of Construction on Three Projects

YEAR

Building

1969

1971

1972

Marshall Broadway Casa de

Towers

II

Redwood

No. 4

Number of units

Number of stories

112

123

136

7

7

7*

685

297

982

600

340

940

Number of panels

Wall

729

Floor

328

Total

1,057

Number of working

days

Fabrication

44

24

29

Erection

21

161⁄2

151⁄2

•Includes penthouse

Electrical work

Almost all of the electrical roughin work is completed at ground level. Conduit ends, junction boxes

and other openings are sealed with

foamed polystyrene, to pre ve n t

them from filling up with concrete,

and secured to reinforcing bars.

Where conduit ends are to connect

across panels—wall to ceiling for example—a precut foamed polystyrene block is fastened over the

butt ends. After the panels have

High strength (5,000

psi) nonshrink grout

overfills the joint

between floor slabs,

filling the keyways in

the edges of both

upper and lower wall

panels.

To tie the floor slabs together a rebar

strap is welded to bars embedded

in the slabs.

been erected, this block is scraped

out and a quick-couple connection

is made.

Because of the repetitive nature of

the electrical work, the electrical

contractor prefabricates conduit assemblies in his shop. Six men then

install the prefabricated conduit

sections in the panels during panel

fabrication.

One electrical contractor feels

that he can bid on this type of job

more accurately than on frame construction for several reasons: the

work is repetitive and clearly defined in shop drawings; it is better

supervised by the architect’s inspector, thus minimizing errors; and

fewer movements of men and materials are required since most of the

work is done at ground level.

Plumbing and heating

Plumbing and heating details are

handled in a fairly conventional

manner. Since plumbing is installed

in chases and not within the panels,

only one plumber is required on the

job during casting of the panels to

install foamed polystyrene blocks.

Waste lines and vents are prefabricated in trees off site and installed

during erection.

Each apartment unit has individual heaters. In warm climates air

conditioning units, if used, can be

through-the-wall types perhaps also

incorporating the heating function.

Drop ceilings in the corridors carry electrical service, water supply

and gas mains and feeders. Vertical

lines and duct work for vents are accommodated in the chases.

Costs

After completion of Marshall

Towers No. 4 in 1969, a Challenge

Developments, Inc. executive stated

that the firm would build a building

of this type for $15 per square foot

anywhere within a 50-mile radius of

its home office. This price included

all costs (except land and financing)

required to complete a building

ready for move-in. Costs have since

gone up, like those for other types

of construction, and the total cost

for a typical structure would now be

closer to $17 per square foot. This

can be compared to costs for wood

frame structures in the San Francisco Bay Area which now average $14

to $17 per square foot and to conventional cast-in-place concrete

s t ru c t u res at $20 to $32 per square

foot. Interiors are finished in the

same manner as in conventional

frame buildings. Walls are textured

and receive paint or wall paper.

Floors are carpeted. The ceiling is

skip-troweled and painted, or a

spray-on acoustical finish is applied

directly to the concrete. Drop ceil-

Development of the method

After wall and floor panels have been

set, foamed polystyrene blocks are

removed from blockouts exposing

electrical conduit ends that are

coupled together.

Section through a typical wall-floor

joint. The large vertical reinforcing bar

extends from foundation to roof.

ings are provided in bath areas,

kitchens and hallways to accommodate electrical, plumbing and mechanical details.

One might ask: if this technique

is so good and so simple, why isn’t

e ve ryone using it? One answer is

that until just recently it has not received a great deal of publicity and

no concerted large-scale effort has

been made to sell it.

An even more important reason

for lack of rapid progress lies in the

fact that, although the construction

procedures are straightforward, the

planning requirements are great.

The planning process demands

practically erro r- f ree detailing and

layout and extremely well thoughtout project scheduling. The entire

building principle is based on a

smooth flow of labor from one task

to another—an assembly line

process.

Any error in planning or deficiency in materials will idle large numbers of workmen until inefficient

field corrections can be made.

Therefore, unless a builder has the

capability for and understands the

importance of thorough planning,

he invites trouble. In any case he

should use the services of an architect and engineer who have had experience using the technique. The

contractor’s superintendent should

be an integral part of the planning

and design team from the very inception of the project.

The site-cast building technique

described here was introduced to

Colorado in 1970 by the Po rt l a n d

Cement Association. At that time, a

joint promotional effort was

launched by the cement industry

and ready mix concrete producers

in the Denver area. In early 1971, the

Colorado Ready Mixed Co n c re t e

Promotional Association was created for the specific purpose of market development. A director was

hired and the intensive promotional

program featuring the site-cast concrete building system was continued.

Acceptance of this building

method in Co l o ra d o, as a result of

the two years of promotional work,

has been beyond expectations. This

success indicates that site-cast

building systems may truly be the

better mouse trap for those ready

mixed concrete producers interested in expanding the markets for

their products.

PUBLICATION#C720324

Copyright © 1972, The Aberdeen Group

All rights reserved