Mina Al Hosn 1394 BIPV-s

advertisement

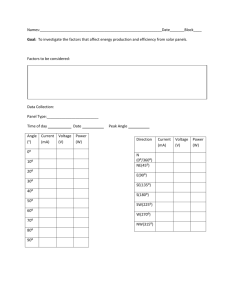

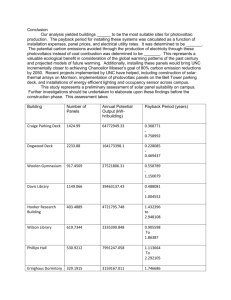

1 Mina Al-Hosn 1394 BIPV The Challenge 2 3 Challenge of the design: • PV panels must integrate the architecture's beauty • Optimize the reception of solar energy • PV must fit the thermal insulation of the facades & be well cooled to prevent losses • Heavy duty hardware is used: PV panels, cables & connectors as well as inverters must be heavy duty to be alive during >25 Y • Optimize the string distribution to minimize shadowing effect 4 Architectural BIPV: • • • At the beginning of this project, in 2008 until the decision in 2011, the only PV for architecture was the “Thin Film” Thin Film best efficiency was 11.3% (CIGS), now we find 13.5% Another new solution developed in the EPFL and manufactured in the UAE which is a selective filter reflecting only one color from the solar spectrum! We get an efficiency reduction not more than 10%. So using this technology we can use the highest efficiency in panels without important reduction due to this filter! We used dummy panels which are exactly the same as the normal (to prevent color change within the next 25 years) but with special cut! 5 Optimizing solar reception: 1. Facades: East, South, West or North ? • In Beirut East, South or West have approx. the same capture about 1’000 Kwh/sqm/a • We used the East & West since the south had louvers to protect from solar rays in summer & help in heating in winter! 2. Emplacement must prevent the most shadowed regions, in our case the most important shadow is from BankMed Bldg. 6 Insulation & panel cooling: • Thermal insulation & panel cooling are performed as follows 1. Air gap behind the panel permitting air circulation to perform natural cooling! 2. Glass-wool behind this air gap to perform thermal insulation Glass-wool Insulation Air gap PV Panel 7 Sustainable materials: • • • Sustainability can not be performed through unknown or unapproved low cost materials! We used Q-Cells German panels, MC Swiss connectors & cables and KACO German inverters, which are all approved and tested in Switzerland and Europe! No investment economy is justified for a lifetime of 25years! 8 String distribution: • • • • Ideally is to get the maximum of MPPT (Max. Power Point Tracker) for each panel! We have about 500 panels of 85Wp each We used 33 inverters (with transformer) of about 2KW each String distribution was performed to get one string for each group of panels having the same direct sun light (at the same time): our strings are for max. 6 panels, due to the high voltage of the Thin Film technologies! 9 Conclusions: 1. Instead of using classical passive cladding materials, we are ready to advice you in BIPV solutions 2. You may invest about 50% to 100% more but certainly you get more than this investment within few years! 3. To be known that the oil price is going up 11.5%/year in the last 18 years! 10 Thank you