Objectives and Learning Activities Beginning Level Nuts, Bolts

advertisement

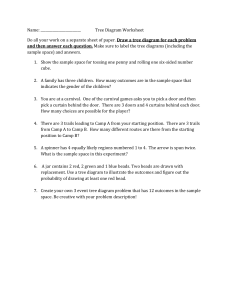

Objectives and Learning Activities Beginning Level Nuts, Bolts & Thingamajigs® Summer Manufacturing Camps Objectives Introduce students to the world of manufacturing through hands-on projects, and site visits to manufacturing facilities. Introduce students to basic entrepreneurial concepts and skills. (Approximately 25% of camp contact time should be spent on entrepreneurial skills introduction and 75% of camp contact time should be spent on manufacturing skills, process, projects, and tours. Some of the entrepreneurial content can effectively be delivered by guest presenters during plant tours and lunch breaks, as well as during evaluations of the projects built by students. Some entrepreneurship lessons have been designed as homework so students can get the family involved.) Desired Outcomes Students learn basic computerized product design using CAD software. Students manufacture a product start to finish using manufacturing equipment, hand tools, or other appropriate aids. Students explore and gain a basic understanding of the challenge of an inventor/entrepreneur in taking a product from idea to business. Students learn about the types of manufacturing jobs available in the local community through tours of local manufacturing companies, presentations and mentoring by local manufacturing experts and other appropriate activities. Students gain an understanding of the kinds of academic and technical training they will need (in high school and beyond) to prepare themselves for 21st century manufacturing careers. Students learn about the teamwork required in an effective manufacturing work environment. Students learn how to practice appropriate shop safety (safety manuals provided by NBT). Students complete both pre- and post-camp surveys online on the first and last days of camp. ©2013 Nuts, Bolts & Thingamajigs, the foundation of The Fabricators & Manufacturers Association, Intl. Instructor Preparation for Camp The staff members who will teach in the camp need to determine an appropriate project for the campers to make. List of products made successfully in previous camps is provided as an appendix. Camp arranges to purchase or obtain donated materials needed to complete the manufacturing product. If the camp does not already have sufficient numbers of CAD software licenses, notify NBT and they will provide SolidWorks Student CAD design software licenses in sufficient quantity to meet the needs of the camp. These 120-day software licenses are donated by SolidWorks through its sponsorship with Nuts, Bolts & Thingamajigs. Software needs to be loaded on computers and design project prepared before the arrival of students for camp. Camp staff prepares shop equipment, hand tools and other elements of the work area to facilitate smooth and efficient movement by the students from one phase to another of the product manufacturing process. Camp staff lines up visits to local manufacturers, guest speakers, etc. to meet learning objectives. Camp staff requests support from local manufacturers, economic development organizations, which can supplement the grant from NBT and the tuition collected from students. During the camp, staff should be prepared to: Obtain signed photo releases as needed from the parents of camp participants. (Form included in materials packet. Document camp activities in photos which will be shared with NBT for inclusion on the foundation’s web site, in magazines published by FMA and in promotional and fundraising materials produced by NBT. (Review the Photo Tip Sheet found in the Appendix to learn what makes great camp photos.) Videotape at least one guest presenter who talks with the students about how they started their business or provides advice about the kind of skills and training it will take to have a successful 21st century manufacturing career. These recordings will be shared with NBT for inclusion in a web-based video library that will be made available to other camps around the country. (Video tip sheet included as an appendix.) (NBT reserves the right to edit video footage or use audio only track as a podcast.) ©2013 Nuts, Bolts & Thingamajigs, the foundation of The Fabricators & Manufacturers Association, Intl. After Camp is Over Reporting Process Complete the post camp report and return to NBT along with the photos and videos. Include contact information for all the local manufacturers/entrepreneurs who participated in your camp as speakers, mentors, donors or hosts for shop visits. All materials due within 14 days of the camp completion date. Send this package to: Diane Engel Nuts, Bolts & Thingamajigs 833 Featherstone Rd. Rockford, IL 61107 DianeE@fmanet.org 815-381-1338 ©2013 Nuts, Bolts & Thingamajigs, the foundation of The Fabricators & Manufacturers Association, Intl. Appendix 1 Past Camp Manufacturing Projects The following represent the kinds of projects that were constructed in camps from 2007-2013 Key chains Dice and chess pieces Windmill Soda can airplane Bridge Rube Goldberg project Assemble robots CD/DVD holders Ball-drop game Picture frames Jet toys, steel-can rovers Personal electronic device holder(cell phone, MP3 player) Single hole paper punch Grill Candle holders Metal candle holder Rose flower Steel butterflies Storage box Star Plant holder Radio-controlled car Radio-controlled helicopter Lawn ornament Aluminum accent lamp Dog tags as jewelry, luggage, or pet ID tags Hover craft Machined game Brass ink pen Mill-spec dominos Tool box Bottle opener Table lamp Children's swing Functional metal art objects Pliers Wrought-iron end table Horseshoe coat hook Trivet/hot plate Small decorative welded project Mailbox Metal organizer for electronics components Finger rings Aluminum engraved desk plate Accent lamp Welded artwork Robot Hammer Finger Treadle Thermoformed plastic projects: bottles, cup holders Functional metal art for placement in community Power Tool Dragster Model-size Motorcycle Wind Turbine Electric Guitars ©2013 Nuts, Bolts & Thingamajigs, the foundation of The Fabricators & Manufacturers Association, Intl.