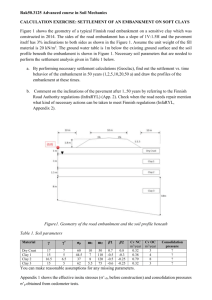

Combined effects of reinforcement and prefabricated vertical drains

advertisement