7 Welding 7.1 OBJECTIVES 7.2 MATERIALS AND EQUIPMENT 7.3

advertisement

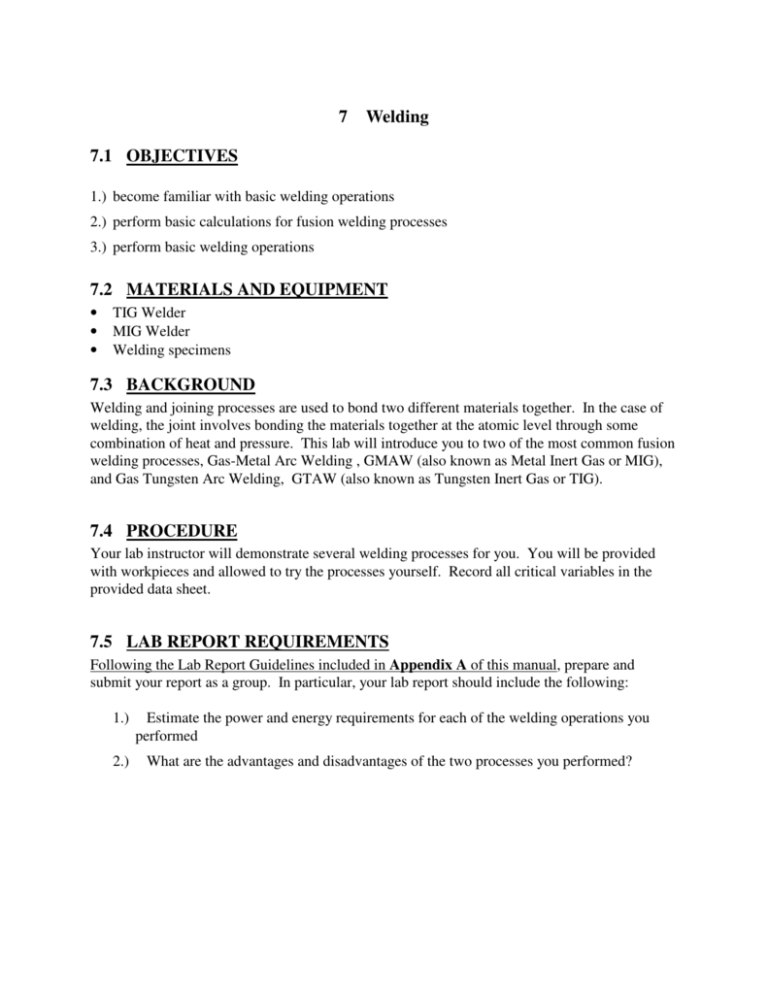

7 Welding 7.1 OBJECTIVES 1.) become familiar with basic welding operations 2.) perform basic calculations for fusion welding processes 3.) perform basic welding operations 7.2 MATERIALS AND EQUIPMENT • • • TIG Welder MIG Welder Welding specimens 7.3 BACKGROUND Welding and joining processes are used to bond two different materials together. In the case of welding, the joint involves bonding the materials together at the atomic level through some combination of heat and pressure. This lab will introduce you to two of the most common fusion welding processes, Gas-Metal Arc Welding , GMAW (also known as Metal Inert Gas or MIG), and Gas Tungsten Arc Welding, GTAW (also known as Tungsten Inert Gas or TIG). 7.4 PROCEDURE Your lab instructor will demonstrate several welding processes for you. You will be provided with workpieces and allowed to try the processes yourself. Record all critical variables in the provided data sheet. 7.5 LAB REPORT REQUIREMENTS Following the Lab Report Guidelines included in Appendix A of this manual, prepare and submit your report as a group. In particular, your lab report should include the following: 1.) Estimate the power and energy requirements for each of the welding operations you performed 2.) What are the advantages and disadvantages of the two processes you performed? Welding Data Sheet: Welding Process 1 – GMAW (MIG) Voltage Setting: ________________ Material Being Welded (type and dimensions): ________________ Welding Wire Type and Size: _________________ Shielding Gas and Flow Rate: _____________________ Measure the weld bead of your most successful weld. Sketch the weld bead here with enough dimensions to estimate the cross-sectional area. Assume that penetration into the metal converges at 45 deg. angles from the edges of the weld bead (90 degree included angle). What was the length of your weld? Make notes about the quality of the weld and any variations you observed as a result of changes to machine settings or welding technique. Welding Process 2 – GTAW (TIG) Current Setting: ________________ Material Being Welded (type and dimensions): ________________ Welding Electrode material and tip shape: _________________ Polarity and Current Settings: ____________________________ Shielding Gas and Flow Rate: _____________________ Average current during most successful weld _______________________ Average voltage during most successful weld _______________________ Measure the weld bead of your most successful weld. Sketch the weld bead here with enough dimensions to estimate the cross-sectional area. Assume that penetration into the metal converges at 45 deg. angles from the edges of the weld bead (90 degree included angle). What was the length of your weld? Make notes about the quality of the weld and any variations you observed as a result of changes to machine settings or welding technique.