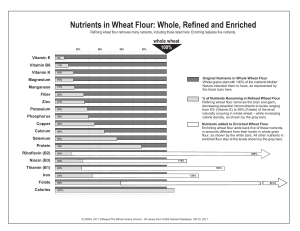

pakistan food fortification scoping study

advertisement