Course Title Operations Management Course Code DE6306 Level 6

advertisement

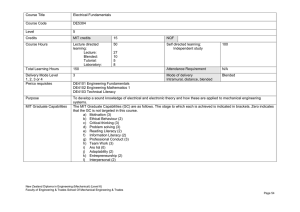

Course Title Operations Management Course Code DE6306 Level 6 Credits MIT credits 15 NQF Course Hours Lecture directed learning: Lecture Blended Tutorial: Project 150 45 Self directed learning: Independent study 105 Attendance Requirement N/A Mode of delivery Intramural, distance, blended Blended Total Learning Hours 10 15 10 10 Delivery Mode Level 1, 2, 3 or 4 Pre/co requisites 3 Purpose To develop an understanding of the principles of production operations management and its application to engineering production operations management The MIT Graduate Capabilities (GC) are as follows. The stage to which each is achieved is indicated in brackets. Zero indicates that the GC is not targeted in this course. a) Motivation (3) b) Ethical Behaviour (2) c) Critical thinking (3) d) Problem solving (3) e) Reading Literacy (2) f) Information Literacy (2) g) Professional Conduct (3) h) Team Work (3) i) Aro hā (0) j) Adaptability (2) k) Entrepreneurship (2) l) Interpersonal (2) MIT Graduate Capabilities DE6305 Quality and Reliability New Zealand Diploma in Engineering (Mechanical) (Level 6) Faculty of Engineering & Trades School Of Mechanical Engineering & Trades Page 102 Learning Outcomes Outline of Content Learning and Teaching Methods Assessment Valid/Reliable LO1 Explain and discuss the principles and strategies associated with engineering operations management. Principles and definitions of production and operations management Interactive learning will be the primary learning method, which will enable one-on-one contact, group work and greater group interaction and cohesion. Assessment Type Weighting Assignment Project Project 40% 40% 20% LO2 Analyse facilities and carry out layout planning Facilities and layout planning LO3 Apply the principles and strategies of engineering operations management Work Study, method study, work measurement Process strategies and capacity planning Location strategies Principles of productivity measurement and improvement Materials handling Waste management and reduction LO4 Analyse a process for the purpose of waste management Group work will enable students to engage in class activities encouraging optimal use of the individual‟s preferred learning style while developing the students‟ ability to work together as a team. Site visits will be used to demonstrate to students the range of actual work in an production environment LMS will be used as an interactive workshop, information repository to enable students to access materials presented in the classroom, and a means of interface between the participants to re-enforce the learning in the laboratory and classroom. Resources Required Text, Web links, Equipment, Computer Labs etc as applicable Outcome s Assesse d 1 2,3 4 Formative Assessment: Small structured tasks provide opportunities for ongoing formative assessment of students progress where possible students will do this in groups e.g. crossword puzzles, short quizzes, research assignments, Students are given the opportunity to practise their skills in a structured and supervised environment. This facilitates the opportunity for Q & A and constructive feedback on an ongoing basis especially during the early stage of the project. Summative Assessment: Two assignments on the principles and strategies associated with engineering operations management. LO 1, weighting 40% Two project reports to investigate the theory and application of principles and strategies of engineering operations management components, layout planning and waste management LO 2-4, weighting 60% Learning commons environment including Digital classroom for group research activities and presentation. Internet access Microsoft visual or similar for layout planning. Electronic resources Case study for plant Layout: http://www.slideshare.net/s arangbhutada/case-studyfor-plant-layout-a-modernanalysis-presentation Material on planning the warehouse: http://logistics.about.com/o d/forsmallbusinesses/a/war ehouse_plan.htm Material on design and analysis of layout http://www.proplanner.com/ documents/filelibrary/produ cts/layout_planner/docume nts/Layout_Planner_PDF_7 2B8670215BC5.pdf New Zealand Diploma in Engineering (Mechanical) (Level 6) Faculty of Engineering & Trades School Of Mechanical Engineering & Trades Page 103 Tutorials will enable knowledge to be consolidated and clarified. The student must achieve a min of 50% to pass the course. Waste Management: http://www.eeiu.org/chapter s/philippines2/supplements/ waste-management.ppt Hazardous waste management in India http://ec.europa.eu/environ ment/international_issues/p resentations/haz_waste_m gt_india_state.ppt New Zealand Diploma in Engineering (Mechanical) (Level 6) Faculty of Engineering & Trades School Of Mechanical Engineering & Trades Page 104