Your efficiency is our target

advertisement

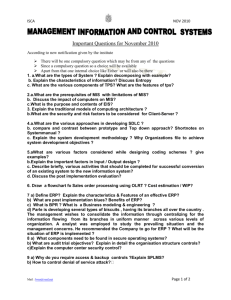

Your efficiency is our target www.creonis.be CreoniS, empowers your efficiency CSD-MES is the answer to the challenges faced by operational management when it comes to the efficiency and quality of the production process and the management of the flow of materials. We offer a modular MES suite, strongly integrated with ERP and shop floor systems. 3 main modules: Performance module Material flow module Parameter module CSD-MES is our own proprietary software, based on Microsoft technology (.Net, SQL) with a constantly evolving product roadmap. CSD-MES modules are strongly integrated with each other and the entire solution can easily be integrated in your existing application landscape. Performance module Monthly Pareto Top 10 Downtime Causes Unplanned Downtimes Real time registration of production output, down times, consumptions (E&F) allows for reliable team and line performance analysis. Standard reports include down time pareto analysis, OAE, OEE, line activity reports, … The production plan is synchronized from the ERP planning system and is visualized into a format that fits the plant management, reflecting the resources required to execute the plan. Monthly OAE Time Bar Chart Through various kinds of devices and interfaces or manual data entry, data from the floor operations can be collected and then published as desired. Material Material flow flow module module Registration Registration of which of which (and how (and much) how much) raw raw materials materials have been have used been in used which in which end products. end products. This allows This allows for : for : • detailed • detailed real time real time inventory inventory of all intermediary of all intermediary and end and end products products • traceability • traceability throughout throughout the complete the complete production production process process • exact • exact cost price cost price calculation calculation CSD-MES CSD-MES trackstracks the movement the movement of inventory of inventory and displays and displays this this information information on anyonrequired any required location location on theonplant the flplant oor. flThis oor. This part ofpart theofsystem the system controls controls material material movements movements in theinplant, the plant, whether whether entered entered manually manually or through or through automated automated systems, systems, and can andprint can identifi print identifi cationcation labels labels for allfor kind allof kind handling of handling units units (pallets, (pallets, boxes,...). boxes,...). This This enables enables controlled controlled recallrecall of semi-fi of semi-fi nished nished or finished or finished goods. goods. In case In case of a market of a market recallrecall the the commercial commercial and fiand nancial financial risks risks are mitigated. are mitigated. Parameter Parameter module module Registration of process and product parameters on each Registration of process and product parameters on level each level of theofproduction process. the production process. A multitude of parameters can becan captured from systems such such A multitude of parameters be captured from systems as LIMS Information Management Systems) and and as (Laboratory LIMS (Laboratory Information Management Systems) measuring equipment. measuring equipment. Actual values of theofparameters are compared with with Actual values the parameters are compared different specifi cations: target, upperupper and lower limit,limit, different specifi cations: target, and lower upperupper and lower blocking limit.limit. Based on the and lower blocking Based onresult the result of this the parameter and consequently ofcomparison this comparison the parameter and consequently the relevant product or process gets agets traffi c light the relevant product or process a traffi c light indicator. indicator. The essence of MES An MES system is a software solution supporting the production/manufacturing processes in a company. Its purpose is to eliminate redundant (often manual) data collection processes, in order to automate the generation of reports on manufacturing intelligence and to provide a bi-directional data exchange between back office reporting systems (like ERP) and operations. It achieves this by streamlining data collection from the shopfloor by connecting to other systems where relevant and by offering a user-friendly interface for manual data entry. Integration of the solution in the daily routines and interfacing with the surrounding systems are therefore major factors when it comes to unlocking it’s true potential. ERP MES : CSD v4 SCADA ERP vs MES? Level 4 Business planning & logistics ISA95 ERP ISA95 Level 3 Manufacturing operations & control ISA95 CSD-MES Levels 2, 1, 0 ISA88 Batch Continuous control control Discrete control ISA88 SCADA (especially Batch) ERP with MES! Comparing the functionalities of an ERP with the functionalities of an MES, it is clear that both are complementary. An ERP covers your business processes, an MES covers your production / manufacturing processes. Unit Time frame Scope Output MES: Manufacturing Execution System ERP: Enterprise Resource Planning www.creonis.be ERP MES $ # days seconds business process production process financials status, efficiency, yield References • A large multi-national brewing group is using the CSD-MES to track the complete production process, on productivity and quality as well as on material flow, from raw materials in the silos to finished pallets on the packaging lines. The software is completely integrated with their ERP solution and other systems like LIMS, WMS and SCADA. • A pharma company (B2C) is using the Performance Module to manage the efficiency of its packaging lines. • The Material Flow Module is in use in several hospitals, to manage the flow of medical instruments from the cleaning and sterilisation area to the operation room (and back). • A pharma company (API manufacturer) is using the Parameter Module to keep track of all product and process parameters. • A discrete manufacturer of beverage containers About CreoniS • Privately owned IT services Company • Based in Leuven, Belgium is using CSD-MES to track the inventory of the materials and goods in the warehouse, and to record batch-related production data. • info@creonis.be • CreoniS BVBA Oude Markt 25 3000 Leuven • http://www.creonis.be