Equipment Types - Blog de Logística

advertisement

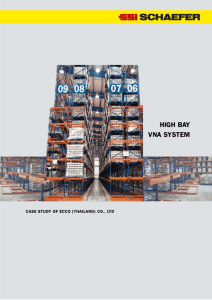

Equipment Types Peter Baker Cranfield School of Management Agenda • Palletised storage and handling equipment • Conveyors and automated guided vehicles • Carton and small parts storage • Carton transport and sortation equipment Block stacking Block stacking Block stacking Advantages • High density • Low cost • Operated by normal counterbalanced fork lift truck Disadvantages • Limited height • possible crushing (NB pallet collars) • stability • Honeycombing • Accessibility Drive in / through Drive-in racking Source: Redirack Drive in / through racking Advantages Disadvantages • High density • Relatively high cost • No crushing of loads • Limited pallet types • Height • Tight tolerances • possible rack damage • driver strain • Honeycombing • Accessibility • Special sprinklers Push back racking Push back racking Advantages Disadvantages • High density • High cost • Height • Last in first out (LIFO) • Accessibility by row (rather than by stack) • Limited utilisation factor • Limited accessibility • Maintenance • Special sprinklers Pallet live storage Pallet live storage Source: Jungenheinrich Pallet live storage Advantages Disadvantages • High density • High cost • Height • Limited utilisation factor • Accessibility by row (rather than by stack) • Limited accessibility • First in first out (FIFO) • Warehouse flow (may be advantage or disadvantage) • Tolerances / maintenance • Special sprinklers Adjustable pallet racking Adjustable pallet racking served by counterbalanced fork lift truck Note: typical aisle width 3.5 metres Adjustable pallet racking served by reach truck Note: typical aisle width 2.7 metres Source: Linde Adjustable pallet racking served by articulated truck Note: typical aisle width 2.0 metres Source: Aisle-Master Double deep racking Source: Link 51 Adjustable pallet racking Advantages • Individual pallet access • Relatively low cost • Relatively easy to reconfigure Disadvantages • Relatively poor use of floor area • Floor surface critical over 8 metres • Height (typically up to 10 metres) • Suitable for ground floor picking Double deep Double deep • Improved floor utilisation • Reduced pallet access Powered mobile racking Powered mobile racking Source: Redirack Powered mobile racking Advantages Disadvantages • Good use of floor area • Slow in operation • High density • Possible queuing • Individual pallet access • High cost • Floor reinforcement • Special sprinklers Narrow aisle racking Note: typical aisle width 1.7 -1.8 metres Narrow aisle racking Typical narrow-aisle “combi” truck for pallet movements and order picking Narrow aisle racking Advantages • Height (typically up to 14 metres) • Good use of floor area • Individual pallet access Disadvantages • Floor surface critical • Specialist (and high cost) trucks • Usually needs P&D stations (for pick up and deposit) Automated storage and retrieval system (AS/RS) Stacker crane on a transfer car Source: Siemens “Curve-going” cranes Source: Jungheinrich. Automated satellite crane Source: Jungheinrich. Rack clad building AS/RS systems Advantages • Height (typically up to 20-40 metres) • Good use of floor area (typically 1.5-1.8 metre aisles) • Individual pallet access (or deeper) • Fast • Reliable • Low running costs Disadvantages • High capital costs • Strong foundations • Building / fire regulations • Planning permission • Inflexible (suited to pallet-in / pallet-out operations) • Unit load dimension limitations Typical location utilisations (reserve storage) Adjustable Doublepallet deep racking Location utilisation 90% 85% Narrow aisle Block / drive-in 90% 70% (i.e. % of locations that can be filled before impacting on operational efficiency) Note: actual figures will vary by exact nature of application. Mobile 90% Live Pushback 85% 80% By storage requirements and picking activity Source: Phillips, E. at www.strategosinc.com/warehouse.htm, accessed 22nd August 2006. By number of pallets stored and number of SKUs 4000 Number of SKUs 3000 To 9m standard selective or power mobile (if slow moving) Free path narrow aisle to 12m Fixed path aisle changing crane 12-16m Fixed path AS/RS 14-20m 2000 Two-deep free path to 8m 1000 Drive-in racks or block stacking or palletflo (if fast moving) to 9m 1000 2000 Two-deep fixed path to 16m Remote recovery unit 14-18m 3000 4000 5000 Number of pallets stored 6000 Source: Hatton, G. (1990) “Materials Handling”, in Gower Handbook of Logistics & Distribution Management, 4th Edition, edited by Gattorna, J., Gower, Vermont, pp. 194-214. © Colby Handling Systems 11-20 6-10 2-5 1 PALLETS ON-HAND By pallets on-hand and popularity Off-site floor storage Mobile storage Pallet flow lanes Doubledeep rack Pushback rack Single-deep rack POPULARITY Source: Frazelle, E.H. (2002) World-Class Warehousing and Material Handling, McGraw-Hill, New York. Decision tree How many pallets per SKU? 1 to 4 pllts/SKU 4-12 pllts/SKU Is throughput per SKU greater than 5 pllts / week? Is throughput per SKU greater than 5 pllts / week? No No Yes Yes Is cost of powered mobile justified? No Yes Powered mobile Is it possible / cost effective for lift height to be: < 11 m? Yes APR (reach truck) No 11-14 m? No Is it possible / cost effective for lift height to be: < 11 m? Is it possible / cost effective for lift height to be: Yes Double-deep, No Yes Narrow aisle No >14 m? >12 pllts/SKU 11-14 m? Yes push-back, or live < 11 m? Narrow aisle 11-14 m? No Yes AS/RS single-deep >14 m? Yes No Yes No Yes AS/RS double-deep >14 m? Yes Block storage, drive-in, or live (Consider options above and below) AS/RS high-density Source: Rushton, A., Croucher, P. & Baker, P. (2006) The Handbook of Logistics and Distribution Management, 3rd Edition, Kogan Page, London. % of respondents Palletised storage equipment 100 90 80 70 60 50 40 30 20 10 0 Wide aisle Narrow aisle AS/RS Equipment type AS/RS = Automated storage and retrieval systems Source: Baker, P. (2004) “The adoption of innovative warehouse equipment”, Logistics Research Network Conference Proceedings, pp. 25-34. Other Automated palletised storage 40 % of respondents 35 30 25 20 15 10 5 0 Single deep Double deep > 2 deep Equipment type Source: Baker, P. (2004) “The adoption of innovative warehouse equipment”, Logistics Research Network Conference Proceedings, pp. 25-34. Any ASRS Roller conveyor Pallet transport Conveyors vs. trucks Pallet transport Factors • Length of movement • Amount to be moved • Number of pick-up points and destinations • Nature of terrain • Speed of movement • Cost • Flexibility required Automated guided vehicles Pallet transport Source: Indumat AGV route example Pallet transport Source: Wagner Small parts storage Non-pallet storage Bins and drawers Suitable for very small parts Standard shelving Can be configured within pallet racking Longspan shelving Fewer uprights Cantilever shelving No uprights. (Also cantilever racking) Mobile shelving Dense storage, but slow access Live storage FIFO. Often used in order picking Mezzanine floors Good use of height but access and stanchions Horizontal carousels Goods to picker system Vertical carousels Uses building height with good access Automated systems Mini-load (i.e. crane) systems Bins and shelving Non-pallet storage Mobile shelving Non-pallet storage Source: Link 51 Carousels Non-pallet storage Source: Siemens Source: Kardex Miniload cranes Non-pallet storage • Miniload storage and retrieval systems • Achieve up to 150 double cycles per hour • Products stored in tote bins or uniform cartons Source: Swisslog % of respondents Non-palletised storage equipment 100 90 80 70 60 50 40 30 20 10 0 Shelving (pedestrian) Shelving (man-up) Carousels Miniload Equipment type Source: Baker, P. (2004) “The adoption of innovative warehouse equipment”, Logistics Research Network Conference Proceedings, pp. 25-34. Other Carton transport • Various trolleys and pallet trucks • Order picking truck (e.g. PPT, free path high level, narrow aisle high level) • Conveyor • Automated retrieval system (e.g. miniload, carousel) • Sorters Pop-up wheel (or roller) sorter • Achieves 2 - 2,500 sorts per hour • Suitable for cartons and tote boxes with a flat base • Integrates with conveyor systems • Suitable for low number of sort destinations (<20) Sliding shoe sorter Source: Siemens • Achieves 4 - 6000 sorts per hour • Suitable for cartons or totes boxes of regular shape and reasonable rigidity Tilt tray sorter • Achieves 10 - 15,000 sorts per hour • Suitable for all types of product with non-stick base • Care needed over range of weights carried Cross belt sorter Source: Siemens • Achieves 10-15,000 sorts per hour • Can handle all shapes of product • More expensive than tilt tray sorters Equipment combinations Source: BT Systems Top 5 lift truck companies Global sales in 2006: 1. Toyota, Japan $5.5 billion 2. Kion Group (Linde), Germany $5.3 billion 3. Jungheinrich, Germany $2.4 billion 4. NACCO (Hyster, Yale), USA $2.3 billion 5. Crown, USA $1.7 billion Source: “Modern Materials Handling” July 2007 Top 10 materials handling systems suppliers Global sales in 2007: 1. Schaefer, Germany 2. Daifuku, Japan 3. FKI, UK 4. Dematic, Germany 5. Mecalux, Spain 6. Vanderlande, Netherlands 7. Swisslog, Switzeralnd 8. Murata, Japan 9. Kardex, Switzerland 10.Columbus McKinnon, USA Source: “Modern Materials Handling” April 2008 $2.4 $2.3 $1.6 $1.0 $0.9 $0.7 $0.7 $0.7 $0.6 $0.6 billion billion billion billion billion billion billion billion billion billion