Hardness Testing: Brinell & Rockwell - Lab Guide

Mechanical properties laboratory practice guide

2015

Hardness test methods

Hardness is resistance of material to plastic deformation caused by indentation.

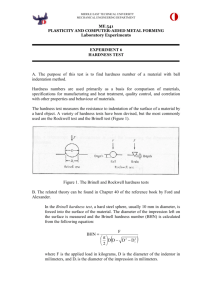

1. Brinell Hardness Test [1]

Dr. J. A. Brinell invented the Brinell test in Sweden in 1900. The oldest of the hardness test methods in common use today, the Brinell test is frequently used to determine the hardness of forgings and castings that have a grain structure too course for Rockwell or Vickers testing. Therefore, Brinell tests are frequently done on large parts. By varying the test force and ball size, nearly all metals can be tested using a Brinell test. Brinell values are considered test force independent as long as the ball size/test force relationship is the same.

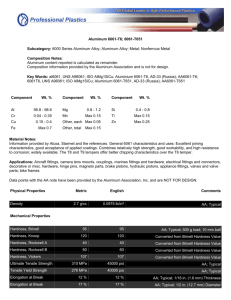

In the USA, Brinell testing is typically done on iron and steel castings using a 3000 Kg test force and a 10 mm diameter carbide ball. Aluminum and other softer alloys are frequently tested using a 500 Kg test force and a 10 or 5mm carbide ball. Therefore the typical range of Brinell testing in this country is 500 to 3000kg with 5 or 10mm carbide balls. In Europe Brinell testing is done using a much wider range of forces and ball sizes. It's common in Europe to perform Brinell tests on small parts using a 1 mm carbide ball and a test force as low as 1kg. These low load tests are commonly referred to as baby Brinell tests.

Standards

Brinell Test methods are defined in the following standards:

ASTM E10 ; ISO 6506

Brinell Test Method

All Brinell tests use a carbide ball indenter. The test procedure is as follows:

The indenter is pressed into the sample by an accurately controlled test force.

The force is maintained for a specific dwell time, normally 10 - 15 seconds.

After the dwell time is complete, the indenter is removed leaving a round indent in the sample.

The size of the indent is determined optically by measuring two diagonals of the round indent using

either a portable microscope or one that is integrated with the load application device.

The Brinell hardness number is a function of the test force divided by the curved surface area of the indent. The indentation is considered to be spherical with a radius equal to half the diameter of the ball. The average of the two diagonals is used in the following formula to calculate the Brinell hardness. where:

HB = the Brinell hardness number

F = the imposed load in kg

D = the diameter of the spherical indenter in mm

d = diameter of the resulting indenter impression in mm

The Brinell number, which normally ranges from HB 50 to HB 750 for metals, will increase as the sample gets harder. Tables are available to make the calculation simple.

1

Applications

Because of the wide test force range the Brinell test can be used on almost any metallic material. The part size is only limited by the testing instrument's capacity.

Strengths

1.

One scale covers the entire hardness range, although comparable results can only be obtained if the ball size and test force relationship is the same.

2.

A wide range of test forces and ball sizes to suit every application.

3.

“Nondestructive”, sample can normally be reused.

Weaknesses

1.

The main drawback of the Brinell test is the need to optically measure the indent size. This requires that the test point be finished well enough to make an accurate measurement.

2.

Slow. Testing can take 30 seconds not counting the sample preparation time.

Laboratory exercise: Brinell hardness test

We will measure the hardness of an aluminum plate.

T he diameter of the spherical indenter in will be 2,5 mm , the imposed load will be 30 kgf, the time of loading will be 30 s. We will measure the indent size with the aid of optical microscope, its division is 1/10 mm.

The Hardness test machines can only be operated by the leader of practice

1. Select a location for the test Remove oil or dirt, but the surface does not need to be polished

2. Make sure the part can be held securely.

3. Raise the spherical indenter according to the red mark on the scale.

4. Apply the 30 kgf load and wait 30 seconds

5. Remove the load

6. Measure the indent size with the aid of the optical microscope.

7. Calculate the Brinell hardness with the appropriate equation, use HB

8. Write a short report on the Brinell results. The standard way to write Brinell hardness of 45 (it is only an example) would be 45 HB.

2. Rockwell Hardness Test [2]

Stanley P. Rockwell invented the Rockwell hardness test. He was a metallurgist for a large ball bearing company and he wanted a fast non-destructive way to determine if the heat treatment process they were doing on the bearing races was successful. The only hardness tests he had available at time were Vickers,

Brinell and Scleroscope. The Vickers test was too time consuming, Brinell indents were too big for his parts and the Scleroscope was difficult to use, especially on his small parts.

To satisfy his needs he invented the Rockwell test method. This simple sequence of test force application proved to be a major advance in the world of hardness testing. It enabled the user to perform an accurate hardness test on a variety of sized parts in just a few seconds.

2

Rockwell test methods are defined in the following standards:

ASTM E18 Metals, ISO 6508 Metals , ASTM D785 Plastics

Types of the Rockwell Test

There are two types of Rockwell tests:

1.

Rockwell : the minor load is 10 kgf, the major load is 60, 100, or 150 kgf.

2.

Superficial Rockwell : the minor load is 3 kgf and major loads are 15, 30, or 45 kgf.

In both tests, the indenter may be either a diamond cone or steel ball, depending upon the characteristics of the material being tested.

Rockwell Scales

Rockwell hardness values are expressed as a combination of a hardness number and a scale symbol representing the indenter and the minor and major loads. The hardness number is expressed by the symbol

HR and the scale designation.

There are 30 different scales. The majority of applications are covered by the Rockwell C and B scales for testing steel, brass, and other metals. However, the increasing use of materials other than steel and brass as well as thin materials necessitates a basic knowledge of the factors that must be considered in choosing the correct scale to ensure an accurate Rockwell test. The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters.

For soft materials such as copper alloys, soft steel, and aluminum alloys a 1/16" diameter steel ball is used with a 100-kilogram load and the hardness is read on the "B" scale. In testing harder materials, hard cast iron and many steel alloys, a 120 degrees diamond cone is used with up to a 150 kilogram load and the hardness is read on the "C" scale. There are several Rockwell scales other than the "B" & "C" scales, (which are called the common scales). A properly reported Rockwell value will have the hardness number followed by

"HR" (Hardness Rockwell) and the scale letter. For example, 50 HRB indicates that the material has a hardness reading of 50 on the B scale.

If no specification exists or there is doubt about the suitability of the specified scale, an analysis should be made of the following factors that control scale selection:

Type of material

Specimen thickness

Test location

Scale limitations

Principe of the Rockwell Test

1.

The indenter moves down into position on the part surface

2.

A minor load is applied and a zero reference position is established

3.

The major load is applied for a specified time period (dwell time) beyond zero

4.

The major load is released leaving the minor load applied

3

The resulting Rockwell number represents the difference in depth from the zero reference position as a result of the application of the major load.

Laboratory exercise: Rockwell-C hardness test

The Hardness test machines can only be operated by the leader of practice

A selection of parts are to be measured using the Rockwell Hardness tester.

1. Choose the appropriate scale to suit the material to be tested (scale C)

2. Select a location for the test Remove oil or dirt, but the surface does not need to be polished

3. Make sure the part can be held securely.

4. Raise the 120

0 diamond cone according to 10 kgf pre-load.

5. Zero the C-scale

6. Apply the 140 kgf main load and wait until the indicator stops moving

7. Remove the load

8. Take a reading. The C scale should be between 20 and 70.

9. Write a short report on the Rockwell results. The standard way to write Rockwell hardness of 45 (it is only an example) on the C scale would be 45 HRC.

3. Tensile test [3]

Basic definitions

The Stress term stress (s) is used to express the loading in terms of force applied to a certain cross-sectional area of an object. stress distribution may or may not be uniform, depending on the nature of the loading condition. For example, a bar in pure tension will essentially have a uniform tensile stress distribution. The in an axially loaded bar is simply equal to applied force divided by the bar's cross-sectional area.

The loaded stress the

Strain

Strain is the response of a system to an applied stress. When a material is loaded with a force, it produces a stress, which then causes a material to deform. Engineering strain is defined the amount of deformation in the direction of the applied force divided the initial length of the material. For example, the strain in a bar that is being stretched in tension is the amount of elongation (or change in length) divided by its original length. as by

Elastic deformation

If the stress is small, the material may only strain a small amount and the material will return to its original size after the stress is released. This is called elastic deformation, because like elastic it returns to its unstressed state. Elastic deformation only occurs in a material when stresses are lower than a critical stress called the yield strength. If a material is loaded beyond it elastic limit, the material will remain in a deformed condition after the load is removed. This is called plastic deformation.

4

Engineering and True Stress and Strain

The discussion above focused on engineering stress and strain, which use the fixed, undeformed crosssectional area in the calculations. True stress and strain measures account for changes in cross-sectional area by using the instantaneous values for the area. The engineering stress-strain curve does not give a true indication of the deformation characteristics of a metal because it is based entirely on the original dimensions of the specimen, and these dimensions change continuously during the testing used to generate the data.

Engineering stress and strain data is commonly used because it is easier to generate the data and the tensile properties are adequate for engineering calculations. When considering the stress-strain curves in the next section, however, it should be understood that metals and other materials continues to strain-harden until they fracture and the stress required to produce further deformation also increase.

Tensile Properties

Tensile properties indicate how the material will react to forces being applied in tension. A tensile test is a fundamental mechanical test where a carefully prepared specimen is loaded in a very controlled manner while measuring the applied load and the elongation of the specimen over some distance. Tensile tests are used to determine the modulus of elasticity, elastic limit, elongation, proportional limit, reduction in area, tensile strength, yield point, yield strength and other tensile properties.

The main product of a tensile test is load versus elongation curve which then converted into a stress versus strain curve. Since both the engineering stress and the engineering strain are obtained by dividing the load and elongation by constant values (specimen geometry information), the load-elongation curve will have the same shape as engineering stress-strain curve. The stress-strain curve relates the applied stress to the resulting strain and each material has its own unique stressstrain curve. A typical engineering stress-strain curve is shown below. If true stress, based on the actual crosssectional area of the specimen, is used, it is found that the stress-strain curve increases continuously up to fracture. a is the the

Linear-Elastic Region and Elastic Constants

As can be seen in the figure, the stress and strain initially increase with a linear relationship. This is the linear-elastic portion of the curve and it indicates that no plastic deformation has occurred. In this region of the curve, when the stress is reduced, the material will return to its original shape. In this linear region, the line obeys the relationship defined as Hooke's Law where the ratio of stress to strain is a constant.

The slope of the line in this region where stress is proportional to strain and is called the modulus of elasticity or Young's modulus . The modulus of elasticity (E) defines the properties of a material as it undergoes stress, deforms, and then returns to its original shape after the stress is removed. It is a measure of the stiffness of a given material. To compute the modulus of elastic , simply divide the stress by the strain in the material

5

Yield Point

In ductile materials, at some point, the stress-strain curve deviates from the straight-line relationship and

Law no longer applies as the strain increases faster than the stress. From this point on in the tensile test, some permanent deformation occurs in the specimen and the material is said to react plastically to any further increase in load or stress. The material will not return to its original, unstressed condition when the load is removed. In brittle materials, little or no plastic deformation occurs and the material fractures near the end of the linear-elastic portion of the curve.

With most materials there is a gradual transition from elastic to plastic behavior, and the exact point at which plastic deformation begins to occur is hard to determine. Therefore, various criteria for the initiation of yielding are used depending on the sensitivity of the strain measurements and the intended use of the data.

For most engineering design and specification applications, the yield strength is used.

The yield strength is defined as the stress required to produce a small, amount of plastic deformation.

Some materials such as gray cast iron, soft copper and aluminum exhibit essentially no linear-elastic behavior. For these materials the usual practice is to define the yield strength as the stress required to produce some total amount of strain. Offset yield point (proof stress): When a yield point is not easily defined based on the shape of the stress-strain curve an offset yield point is arbitrarily defined. The value for this is commonly set at 0.1 or 0.2% strain compared to original gauge length. The offset value is given as a subscript, e.g., R p0.2

=310 MPa. High strength steel and aluminum alloys do not exhibit a yield point, so this offset yield point is used on these materials.

Ultimate Tensile Strength

The ultimate tensile strength (UTS) or, more simply, the tensile strength, is the maximum engineering stress level reached in a tension test. The strength of a material is its ability to withstand external forces without breaking. In brittle materials, the UTS will at the end of the linear-elastic portion of the stress-strain curve or close to the elastic limit. In ductile materials, the UTS will be well outside of the elastic portion into the plastic portion of the stressstrain curve.

On the stress-strain curve above, the UTS is the highest point where the line is momentarily flat. Since the UTS is based on the engineering stress, it is often not the same as the breaking strength. The UTS may not be completely representative of the highest level of stress that a material can support, but the value is not typically used in the design of components anyway. For ductile metals the current design practice is to use the yield strength for sizing static components. However, since the UTS is easy to determine and quite reproducible, it is useful for the purposes of specifying a material and for quality control purposes. On the other hand, for brittle materials the design of a component may be based on the tensile strength of the material.

Breaking strength

The stress coordinate on the stress-strain curve at the point of rupture.

Measures of Ductility (Elongation and Reduction of Area)

The ductility of a material is a measure of the extent to which a material will deform before fracture. The amount of ductility is an important factor when considering forming operations such as rolling and extrusion. It also provides an indication of how visible overload damage to a component might become before the component fractures. Ductility is also used a quality control measure to assess the level of impurities and proper processing of a material.

6

As previously discussed, tension is just one of the way that a material can be loaded. Other ways of loading a material include compression, bending, shear and torsion, and there are a number of standard tests that have been established to characterize how a material performs under these other loading conditions.

Introduction to the measurement:

The force and elongation signals from the Tensile test machine are forwarded to the enclosed computer, and they are read out with a special Labview program. The program will display the force-elongation diagram.

The green sign indicates the operation of the data collection.

The screen of the special Labview program

After the termination of the measurement the program displays the graph. You can read out the data with the aid of two cursors. The force is displayed in Newton (N),, the elongation is displayed in micrometers

(μm) .

Measurement data saving and acquisition

The program saves the data file in .csv format. The data saved in D:\szakito\meresek folder.

CSV (Comma Separated Values) is an ASCII data file.

If you are using an MS Excel program with international setting it can read the CSV file directly.

If you are using an MS Excel program with Hungarian regional setting first change all the column separating comma sign (,) into semicolon sign (;). After it change all dot sign (.)into comma sign (,). The first column in data file is the elongation in micrometers (μm), the second column is the force in Newton

(N)for example:

326,0;26,2

344,8;33,0

364,5;41,9

...

In order to display the graph in Excel mark the two columns, and start the XY point graph diagram displaying option with a line between the dots. Give values and units to the two axis of diagram.

7

F m

F e

F c

Force in

Newton break

l

Elongation in micrometers

Sample Force-elongation diagram generated with Excel without values

You can read out from the diagram: F e is the offset yield force; F m is the maximal force,

F c is the breaking force;

l is the plastic (non-elastic) elongation of the specimen.

We negotiate the beginning non-linear portion of the diagram, it is supposed to the gripping

Failures of the specimen (all such diagram-beginning of metals should be linear).

Laboratory exercise: Tensile test

The tensile test machine can only be operated by the leader of practice!

1.

Prepare the aluminium plate according to the drawing below. Fix the plate into the clamp and from it with the aid of the rasp. l

0 a

A

0 b l c l

1

The scales of the drawing can be calculated using the following equations: l

0

k A

0 l c

l

0

1 , 5

5 , 65

A

0 a

b distance of the inner marks: initial gauge length.

l

0

1 , 5 a

b distance of the outer marks: length of the reduced cross section.

8

Where:

A

0

=a*b is the cross section of the reduced area,

Plate thickness: a= 2 mm ,

Plate width: b= 14 mm

2.

Mark the calculated l

0

,l c length on the plate with the aid of a scratcher and Vernier calliper.

3.

Fix the test specimen into the gripping heads of the machine.

4.

Initialise the measurement program with Start button

5.

Begin the test with the machine!

6.

The black indicator shows the actual force, the red indicator will stop at the maximal force (F m

).

7.

After the break of the specimen terminate machine work with Stop button.

8.

Terminate the program with Stop button.

9.

Give a name for the generated CSV data file, and save it to a virus-free pen drive.

PZO made coordinate measuring microscope Above: measuring of the specimen thickness after the break : a u

(microscope ocular picture)

Below: measuring reed with 1/100 mm scale

The the specimen thickness after the break: a u cannot be measured with Vernier caliper, because it is so small, that cannot be see by the naked eye. This a u can only be measured with the aid of the coordinate measuring microscope. First set the crossing line in the ocular to the beginning of the after break thickness, after it at the end of the thickness. Read the two values from measuring reed, it’s difference gives the a u value.

9

Calculated values:

Tensile strength is measured in units of force per unit area. In the SI system, the units are Newton per square meter (N/m²) or Pascal (Pa), with prefixes as appropriate. If You substitute the area in mm² and the Force in

Newton, You will have MPa units for the stress calculations.

Ultimate tensile strength (UTS):

Breaking strength:

m c

F m

A

0

F c

A u

MPa

MPa

Relative elongation :

Relative elongation based on

l=l u

-l

0

:

l u

l

0

100 % l

0

l

100 % l

0

Offset yield point

(proof stress):

R p0,2

F e

A

0

M Pa

Relative reduction of area:

A

0

A u

A

0

100 %

Where:

F e is the offset yield force

F m is the maximal force,

F c is the breaking force,

A

0

is the initial cross section of the specimen,

A u

is the cross section of the specimen after break, l

0 is the distance of the inner marks: initial length, l u is the distance of the inner marks after break.

The tensile test machine draws force-elongation diagram. From force-elongation diagram calculate some values, and draw stress-strain (

:

) diagram. The main advantage of stress-strain diagram: it is independent from the cross section of the specimen.

Control questions:

1. Define the hardness!

2. List the steps of Brinell hardness measurement!

3. List the steps of Rockwell hardness measurement!

4. Define stress and strain!

5. Equations of calculated values for tensile test.

Literature:

[1] http://www.instron.us/wa/applications/test_types/hardness/brinell.aspx

[2] http://www.instron.us/wa/applications/test_types/hardness/rockwell.aspx

[3] http://www.ndt-ed.org/EducationResources/CommunityCollege/Materials/Mechanical/Tensile.htm

10

Report of the mechanical

Made by:

…………………………………… ………

properties laboratory practice

Name neptun code, group identification

Leader of laboratory practice: Date: Note:

1. Brinell hardness measurement

Steps of Brinell hardness measurement :

Equipment used for the measurement:

1.

2.

Number Name Manufacturer

Recorded, measured and calculated values:

Initial data:

Measured data:

Sample identification:

D (diameter of the spherical indenter in mm):

F (imposed load in kgf): d (diameter of the resulting indenter impression in mm):

Brinell hardness value: Calculated value:

Calculations: equation with letters and substitution:

Explanation of the results:

Type

11

2. Rockwell hardness measurement

Steps of Rockwell hardness measurement :

Equipment used for the measurement:

Number Name

1.

2.

Recorded and measured values:

Manufacturer

Initial data:

Measured data:

Explanation of the results:

Sample identification:

Indentder material, shape and measure:

F (pre-load) kgf:

F (main load) kgf:

Rockwell hardness value:

Type

12

3. Tensile test

Drawing of the aluminium plate specimen before the test with it’s measures!

Steps of the tensile test::

Equipment used for the measurement:

1.

2.

3.

Number Name

Measured and calculated values:

Manufacturer Type

Initial data:

Initial plate width b

0

:

Initial cross section area A

0

:

Force data.

Data measured after break:

Initial length l

0

:

Length of the reduced cross section l c

:

F e

(Yield force):

F m

(Maximal force):

F c

(Breaking force): a u

(plate thickness after break): b u

(plate width after break):

A u

(cross section of the specimen after break):

Calculated values

Initial plate thickness a

0

: l u

(length of the inner marks after break):

l=l u

-l

0

R p0,2

(yield stress) MPa:

σ m

(UTS) MPa:

σ c

(Breaking strength) MPa:

ε (relative elongation) %:

Ψ

( relative reduction of area ) %:

Calculations: equations with letters and substitution:

Stress-strain (

:

) diagram:

Explanation of the results:

13