Westernacher Utilities Case Study:

OCC - Operation Control Cockpit

Utilities

The Customer

As a medium-sized German power generator, Mark-E supplies about 6.6 billion kilowatt hours of electricity per year to over 230,000 retail

and business customers, 1,800 industry customers, and several energy retailers. Mark-E possesses power plants with an installed generating

capacity of over 1,000 megawatts. In 2005 overall sales totaled about €617m.

The Task

Mark-E formed a cooperation with another power generator for a

joint investment in a new 800 MW gas-steam power plant. Within

this cooperation Mark-E has the responsibility for plant operation.

A plant operation contract between the cooperation partners also

stipulates commercial rules for accounting and billing of the plant

operation costs.

As a consequence, Mark-E needed an efficient software application

that integrates the technical and commercial information management of the plant operation process.

The new application had to provide a user-friendly yet comprehensive interface to ensure consistent use by frontline personnel with

technically oriented operations backgrounds. The functionality of

the application had to reflect the plant operation process with its

defined roles representing specific responsibilities and authorizations. The technical solution had to be seamlessly integrated into

the existing SAP ERP system landscape.

© Westernacher Consulting AG. All Rights Reserved. | www.westernacher.com

The Solution:

OCC - Operation Control Cockpit

Westernacher has developed the

Operation Control Cockpit (OCC) as a

SAP/JAVA Web-Application that can be

adjusted specifically for the implementation of individual plant management

processes.

Westernacher Utilities Case Study:

OCC - Operation Control Cockpit

OCC Highlights

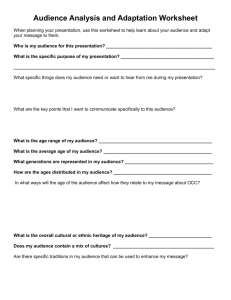

The Operation Control Cockpit (OCC) is a SAP/JAVA Web-Application that can be adjusted specifically for the implementation of

your plant management process:

••

The daily plant management business is represented in a

transparent order management.

••

The OCC, with its standardized interface architecture, meets

the requirement for a seamless integration of the new application into the existing SAP ERP environment

••

The technical structure of a power plant (incorporating the

KKS-System) serves as the master of the order management

explorer structure.

••

Processing of OCC orders is represented in a roleandstatusbased register control.

••

Actual costs and purchase commitments can be evaluated

in detail to monitor cost allocation within the plant and control budgets for projects and/or technical departments.

The daily plant management process is represented in OCC

by a transparent list of orders. Various order types can be

differentiated, e.g. trouble shooting, maintenance and special projects related to plant revisions and investments.

Order type specific processing and related responsibilities

of various departments are captured and taken into account. The function of plant management is given a clear

structure according to technical and/or organizational

requirements.

For Mark-E the technical structure of their power plants

(partially based on the KKS system) served as the model for

the explorer-navigation orientation in OCC’s order management process. Based on a reorganization that included the

implementation of an internal client and contractor relationship between the departments for plant operation and

plant services, Mark-E developed an overall model for the

plant management process.

Since the OCC web front-end incorporates the internal

organization structure and process-specific technical language all of which is familiar to operations personnel, the

system is intuitive to use. OCC obviates the need to use the

complex SAP standard user interface. This increases user acceptance and thus ensures the quality of the collected data.

The modular design of the OCC control logic facilitates flexible adjustments to changes within the business processes.

With respect to state regulations and/or cooperation

contracts for plant management, the OCC supplies detailed,

structured and traceable invoicing data.

With its integrated functionality the Operation Control

Cockpit is the core application for Mark-E´s daily business

of plant management. Approximately 150 employees on

three different sites rely on OCC to help organize plant

maintenance. So far 10 small- and medium-sized power generation plants with an overall installed capacity of 1,000

MW are incorporated in the OCC. The additional 800 MW

gas-steam power plant that triggered the OCC development

project has been in operation since mid-2007.

Westernacher Utilities Case Study:

OCC - Operation Control Cockpit

SAP Backend

•• To represent the complex technical structures of a power

plant in a hierarchical Explorer-like structure, the OCC

Backend uses the functionality of the SAP Project System

(PS).

•• The integrated link to the SAP modules MM and FI enables

the user to dispose order related resources within the OCC

web front-end.

•• Further processing of listed evaluation results (ongoing

selection/filtering, drill-down, etc.) is supported by SAP

List Viewer functionality.

•• Actual costs and purchase commitments can be

evaluated in detail to monitor cost allocation. Evaluation

results can also be used as reference for expenditure

based invoicing via the SAP SD module.

•• For internal management accounting and reporting purposes, the Operation Control Cockpit also provides required

connection to the SAP CO module.

•• Through transaction links to SAP standard reports, the

OCC provides comfortable evaluation functionalities for

plant operation costs.

Westernacher & Partner Consulting Limited

3rd Floor | 14 Hanover St. | Hanover Square | London W1S 1YH | United Kingdom

Phone: +44 870 383 0272 | Fax: +44 870 383 6272

Westernacher Business Management Consulting AG

Im Schuhmachergewann 6 | 69123 Heidelberg | Germany

Phone: +49 6221 187 62- 0 | Fax: +49 6221 187 62 - 11

E-Mail: info@westernacher.com | www.westernacher.com

© Westernacher Consulting AG. All Rights Reserved.

tion

Informta

Contac

m

ooks

acher.co

n

r

Roger Br

e

t

s

e

oks@w

roger.bro

2

38 30 27

0

7

8

4

4

+

Phone: