ACC 204 Chapter 9 PPT Handout

advertisement

Dutchess Community College

ACC 204 – Managerial Accounting

Quiz Prep Chapter 9

Budgetary Planning

Peter Rivera

March 2011

Disclaimer

This Quiz Prep is provided as an outline of

the key concepts from the chapter.

It is not intended to be comprehensive or

exhaustive.

Quizzes may include material from the

classroom lectures, the text or the homework

assignments.

ACC 204 Chapter 9

1

Primary Benefits of Budgeting

The primary benefits of budgeting are:

(1) It requires all levels of management to plan ahead

and to formalize goals on a recurring basis.

(2) It provides definite objectives for evaluating

performance at each level of responsibility.

(3) It creates an early warning system for potential

problems, so that management can make changes before

things get out of hand.

continued

Primary Benefits of Budgeting

(4) It facilitates the coordination of activities within

the business by correlating the goals of each segment

with overall company objectives.

(5) It results in greater management awareness of the

entity’s overall operations and the impact of external

factors such as economic trends.

(6) It motivates personnel throughout the organization

to meet planned objectives.

ACC 204 Chapter 9

2

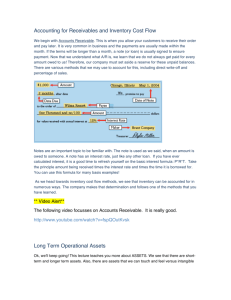

Components of the Master Budget

Sales Budget

Operating

Budgets

Production Budget

Direct Materials

Budget

Manufacturing

Overhead Budget

Direct Labor Budget

Selling & Administration Budget

Budgeted Income Statement

Capital Expenditure

Budget

Budgeted

Balance Sheet

Cash Flow

Budget

Financial

Budgets

Sales Budget

Sales Budgets consists of • Quantity (units)

• Unit Selling Price

Expected Unit Sales

x Unit Selling Price

= Total Sales $

1Q

3,000

60

180,000

Yellow boxes in the

schedules indicate inputs.

All other numbers are either

calculated or carried

forward from a previous

schedule

ACC 204 Chapter 9

2Q

3,500

60

210,000

3Q

4,000

60

240,000

4Q

4,500

60

270,000

Year

15,000

60

900,000

The Unit Selling Price for the year =

Total Sales for the Year

Total Expected Units for the year

3

Production Budget

The 1Q from the next year is

needed for the 4Q Desired Ending

Inventory Calculation

From Sales Budget

Expected Unit Sales

Add: Desired Ending %

Add: Desired Ending Q

Less: Beginning Inv

= Production Quantity

1Q

3,000

20%

700

600

3,100

2Q

3,500

20%

800

700

3,600

3Q

4,000

20%

900

800

4,100

4Q

4,500

20%

1,000

900

4,600

Year Next Yr 1Q

5,000

15,400

The Beginning Inventory for a quarter = the

Ending Inventory from the previous quarter

Balance Sheet

Typically, the Desired Ending Inventory is a % of the next

period’s sales; e.g., 1Q 20% x 2Q Sales of 3,500 = 700

Direct Materials Budget

From Production Budget

Units to be Produced

x Direct Material per Unit

= Total DM needed

Add: Desired Ending %

Add: Desired Ending Q

Less: Beginning Inventory

= RM Purchased

x Cost per RM

= Total Cost of DM Purchase

1Q

3,100

2

6,200

10%

720

620

6,300

4

25,200

Balance Sheet

Similar process as in the

Production Budget

ACC 204 Chapter 9

2Q

3,600

2

7,200

10%

820

720

7,300

4

29,200

3Q

4,100

2

8,200

10%

920

820

8,300

4

33,200

4Q

4,600

2

9,200

10%

1,020

920

9,300

4

37,200

Year Next Yr 1Q

10,200

124,800

The 1Q from the next year is

needed for the 4Q Desired Ending

Inventory Calculation

4

Labor Budget

From Production Budget

Units to be Produced

x Direct Labor Hours per Unit

= Total # of Direct Labor Hours

x Direct Labor Cost per Hour

= Total Labor Cost

1Q

3,100

2

6,200

10

62,000

2Q

3,600

2

7,200

10

72,000

3Q

4,100

2

8,200

10

82,000

4Q

4,600

2

9,200

10

92,000

308,000

Manufacturing Overhead Budget

The Manufacturing Overhead Budget has 2 parts:

• Variable Costs

• Fixed Costs

ACC 204 Chapter 9

5

Manufacturing Overhead Budget

In this example, The Variable Manufacturing Overhead is assumed

to be allocated based on Direct Labor Hours as calculated in the

Direct Labor Budget.

1Q

6,200

Total # of Direct Labor Hours

Variable

Indirect materials

Indirect Labor

Utilities

Maintenance

Total variable costs

Indirect materials

Indirect Labor

Utilities

Maintenance

Total variable costs

$

$

$

$

$

1.00

1.40

0.40

0.20

3.00

6,200

8,680

2,480

1,240

18,600

2Q

7,200

$

$

$

$

$

1.00

1.40

0.40

0.20

3.00

7,200

10,080

2,880

1,440

21,600

3Q

8,200

$

$

$

$

$

1.00

1.40

0.40

0.20

3.00

8,200

11,480

3,280

1,640

24,600

4Q

9,200

$

$

$

$

$

Year

1.00

1.40

0.40

0.20

3.00

9,200

12,880

3,680

1,840

27,600

30,800

43,120

12,320

6,160

92,400

Manufacturing Overhead Budget

+

Total variable costs

1Q

18,600

2Q

21,600

3Q

24,600

4Q

27,600

92,400

Fixed Costs

Supervisory Salaries

Depreciation

Prop Taxes & Insurance

Maintenance

Total Fixed Costs

20,000

3,800

9,000

5,700

38,500

20,000

3,800

9,000

5,700

38,500

20,000

3,800

9,000

5,700

38,500

20,000

3,800

9,000

5,700

38,500

80,000

15,200

36,000

22,800

154,000

57,100

6,200

60,100

7,200

63,100

8,200

66,100

9,200

246,400

30,800

$

8.00

Total OH

/ Direct Labor Hours

OH Rate per hour

ACC 204 Chapter 9

6

Selling & Administrative Expense Budget

Similar to the Manufacturing Overhead Budget,

the Selling & Administrative Expense Budget has

2 parts:

• Variable Costs

• Fixed Costs

Selling & Administrative Expense Budget

In this example, The Variable Selling & Administrative Expenses are

assumed to be based on Sales Units as calculated in the Sales Budget.

+

ACC 204 Chapter 9

Budgeted Sales in Units

1Q

3,000

2Q

3,500

3Q

4,000

4Q

4,500

15,000

Variable Expense

x Selling Commissions Rate

= Selling Commissions

3

9,000

3

10,500

3

12,000

3

13,500

45,000

1

3,000

12,000

1

3,500

14,000

1

4,000

16,000

1

4,500

18,000

15,000

60,000

x Freight-out Rate

= Freight-out Cost

Total Variable

7

Selling & Administrative Expense Budget

+

Total Variable

1Q

12,000

2Q

14,000

3Q

16,000

4Q

18,000

60,000

Fixed Expenses

Advertising

Sales Salaries

Office Salaries

Depreciation

Property Taxes & Insurance

Total Fixed

5,000

15,000

7,500

1,000

1,500

30,000

5,000

15,000

7,500

1,000

1,500

30,000

5,000

15,000

7,500

1,000

1,500

30,000

5,000

15,000

7,500

1,000

1,500

30,000

20,000

60,000

30,000

4,000

6,000

120,000

Total Selling & Administrative

42,000

44,000

46,000

48,000

180,000

Budgeted Income Statement

Sales Budget

Sales Revenues

COGS per Unit

Direct Materials

Direct Labor

Maufacturing Overhead

Total COGS Per Unit

Estimated Total # of Units Sold

- COGS $

= Gross Profit

- Selling & Administrative Expenses

= Operating Income

- Interest Exp

= Income Before Taxes

- Income Tax Expense

= Net Income

ACC 204 Chapter 9

$ 900,000

$

$

$

$

Direct Materials Budget:

2 RM per Unit @ $4

Direct Labor Budget:

2 Hrs per Unit @ $10

8.00

20.00

16.00

44.00

15,000

660,000

240,000

180,000

60,000

100

59,900

12,000

$ 47,900

Manufacturing Overhead

Budget:

2 Hrs per Unit @ $8

Production Budget

Selling &

Administration Budget

8

Capital Expenditure Budget

PP&E, Beginning

+ Purchases:

Truck

- Disposals

= PP&E, Ending

1Q

182,000

2Q

182,000

3Q

192,000

4Q

192,000

10,000

182,000

192,000

Year

10,000

192,000

192,000

Cash Budget

Vtá{ \á ^|Çz4

This example assumes that the company wishes to maintain

a minimum cash balance of $15,000.

They will plan to borrow when the estimated available cash

is below this and plan to repay any borrowings when there is

more than the minimum amount.

There are 2 preliminary schedules that must be calculated:

• Collection of Accounts Receivable

• Payment of Accounts Payable

ACC 204 Chapter 9

9

Cash Budget

Other assumptions include:

• Short Term Investments of $2,000 are to be sold in 1 Q

• Direct Labor is paid in the current quarter

• Manufacturing Overhead in paid in the current quarter;

NOTE that Depreciation is NOT a cash expenditure

• Selling & Administration Expenses are paid in the

current quarter; NOTE that Depreciation is NOT a cash

expenditure

• Income Taxes are paid on an equal quarterly basis

Cash Budget

Collection of Accounts Receivable

In this example it is assumed that 60% of accounts receivable

are collected in the current quarter with the remainder in the

next quarter, e.g.:

1Q Sales = 180,000 * 60% = 108,000 in 1Q

180,000 Total – 108,000 in 1Q = 72,000 in 2Q

Assumption % collected in current Q =

Accts Receivable Opening

1Q

2Q

3Q

4Q

Total Collections

ACC 204 Chapter 9

1Q

60,000

108,000

168,000

60%

2Q

72,000

126,000

198,000

3Q

84,000

144,000

228,000

4Q

96,000

162,000

258,000

10

Cash Budget

Payment of Accounts Payable

In this example it is assumed that 50% of accounts payable

are paid in the current quarter with the remainder in the next

quarter, e.g.:

1Q Purchases = 25,200 * 50% = 12,600 in 1Q

25,200 Total – 12,600 in 1Q = 12,600 in 2Q

Assumption % paid in current Q =

Accounts Payable opening

1Q

2Q

3Q

4Q

Total Payments

Beginning Cash Balance

ADD: Receipts

Collection of Accounts Receivable

Sale of Securities

Total Receipts

Total Available Cash

LESS: Disbursements

Direct Materials

Direct Labor

Manufacturing Overhead: Cash

Selling & Admin Expenses: Cash

Purchase of Truck

Income Tax Expense

Total Disbursements

Excess (Deficiency) of Cash

Total Tax

$12,000 / 4

ACC 204 Chapter 9

12,600

14,600

23,200

27,200

Cash Budget

Balance Sheet

Financing

Borrowings

Repayments + $100 interest

Ending Cash Balance

10,600

12,600

1Q

38,000

2Q

25,500

50%

3Q

15,000

14,600

16,600

31,200

16,600

18,600

35,200

The Beginning Cash =

Ending Cash from

previous Q

4Q

19,400

168,000

2,000

170,000

208,000

198,000

198,000

223,500

228,000

228,000

243,000

258,000

258,000

277,400

23,200

62,000

53,300

41,000

31,200

82,000

59,300

45,000

35,200

92,000

62,300

47,000

3,000

182,500

25,500

27,200

72,000

56,300

43,000

10,000

3,000

211,500

12,000

3,000

220,500

22,500

3,000

239,500

37,900

25,500

3,000

15,000

3,100

19,400

37,900

AR Schedule

AP Schedule

DL Budget

Borrowing to maintain

minimum $15,000

Man. OH Budget

LESS

Depreciation

S & A Budget

LESS

Depreciation

Repay loan

+ interest

11

Capital Expenditure

Budget

Budgeted Balance Sheet

Cash Budget

Cash

Accounts Receivable

Inventory: Finished Goods

Inventory: Raw materials

PP&E

Less: Accumulated Depreciation

= Net PP&E

Total Assets

Accounts Payable

Common Stock

Retained Earnings: Beginning

+ Net Income

= Retained Earnings: Ending

Total Liabilities & Equity

AP Schedule

ACC 204 Chapter 9

Budgeted

Income

Statement

AR Schedule

$

37,900

108,000

44,000

4,080

192,000

48,000

144,000

$ 337,980

18,600

225,000

46,480

47,900

94,380

$ 337,980

4Q Prod. Budget Q

x Est. Unit Cost

4Q RM Budget Q

x Unit Cost

Accum. Depreciation

Beginning (given)

$ 28,800

+ Prod Depreciation

+ S&A Depreciation

Balance Sheet

12